Low-noise power capacitor using damping steel plates

A power capacitor and low-noise technology, which is applied in the field of noise control of high-voltage power equipment, can solve the problems of unsatisfied, no substantial reduction in noise, etc., and achieve the effects of reducing bottom vibration, bottom noise, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

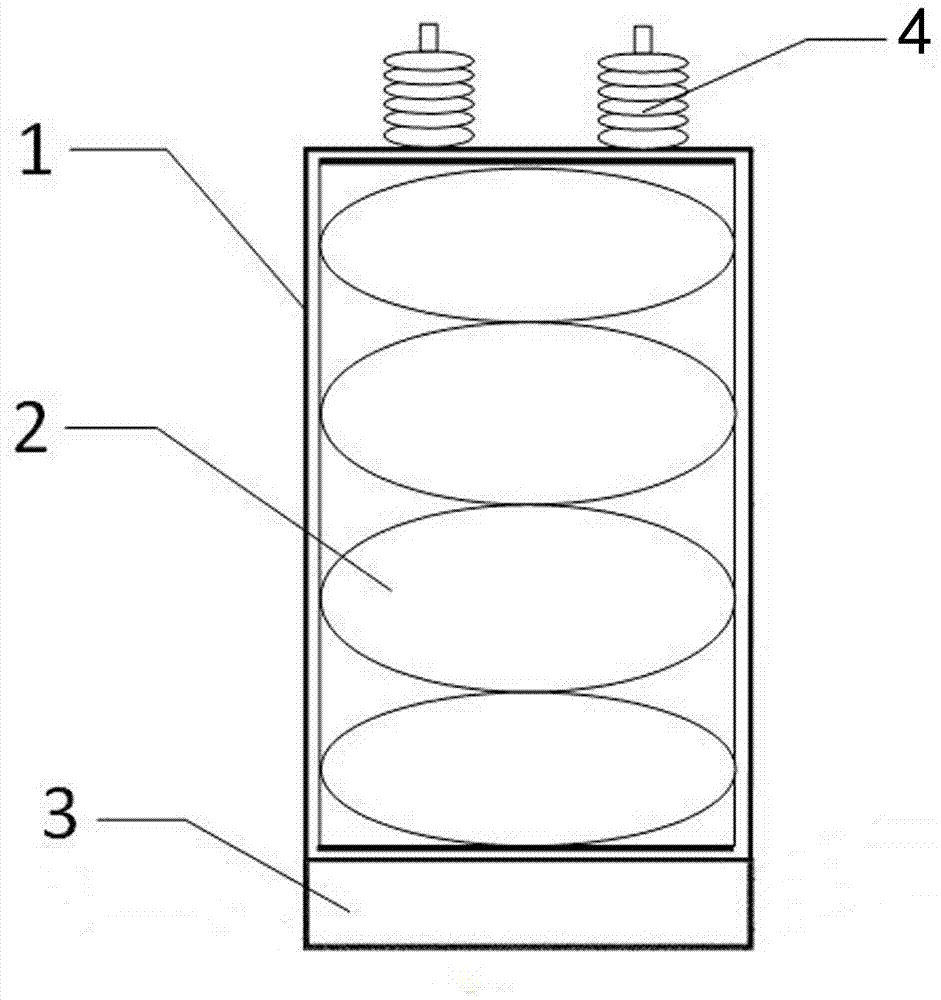

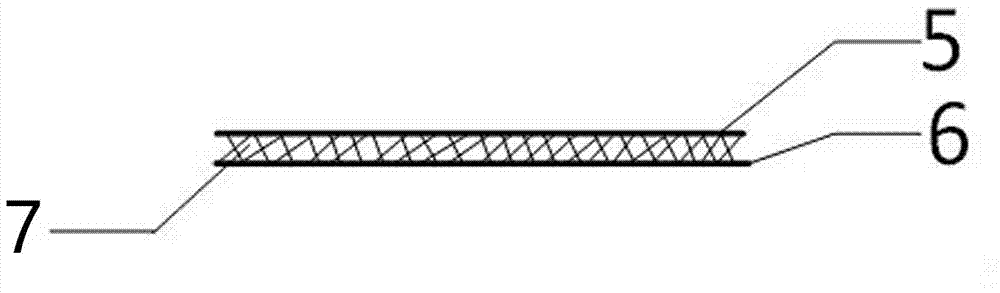

[0022] Such as figure 1 , figure 2 As shown, a low-noise power capacitor using a damping steel plate includes a capacitor case 1, a core 2, a bushing 4 and a sound insulation chamber 3, the bushing 4 is set on the top of the capacitor case 1, and the core 2 is set on the capacitor case 1 Inside, the sound insulation cavity 3 is arranged at the bottom of the capacitor case 1; the sound insulation cavity 3 is a closed cavity structure composed of two layers of steel plates inside and outside, and a damping material 7 is arranged between the outer layer steel plate 6 and the inner layer steel plate 5 , forming a closed cavity structure with three layers.

[0023] The closed cavity structure is fixed to the bottom of the capacitor by welding.

[0024] The inside of the closed cavity is air.

[0025] The thickness of the air layer inside the closed cavity is 20mm-30mm.

[0026] The steel plate is a stainless steel plate with a thickness of 0.5 mm and an area density of 3.95 kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com