Assembled periodic octahedral truss lattice structure

A lattice structure, octahedral technology, applied in building elements, slender elements, improvement of process efficiency, etc., can solve the problems of reducing the intrinsic mechanical properties of the base material, low material utilization, cumbersome post-processing, etc. Improve the value of engineering applications, simplify the production process, and improve the effect of process constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

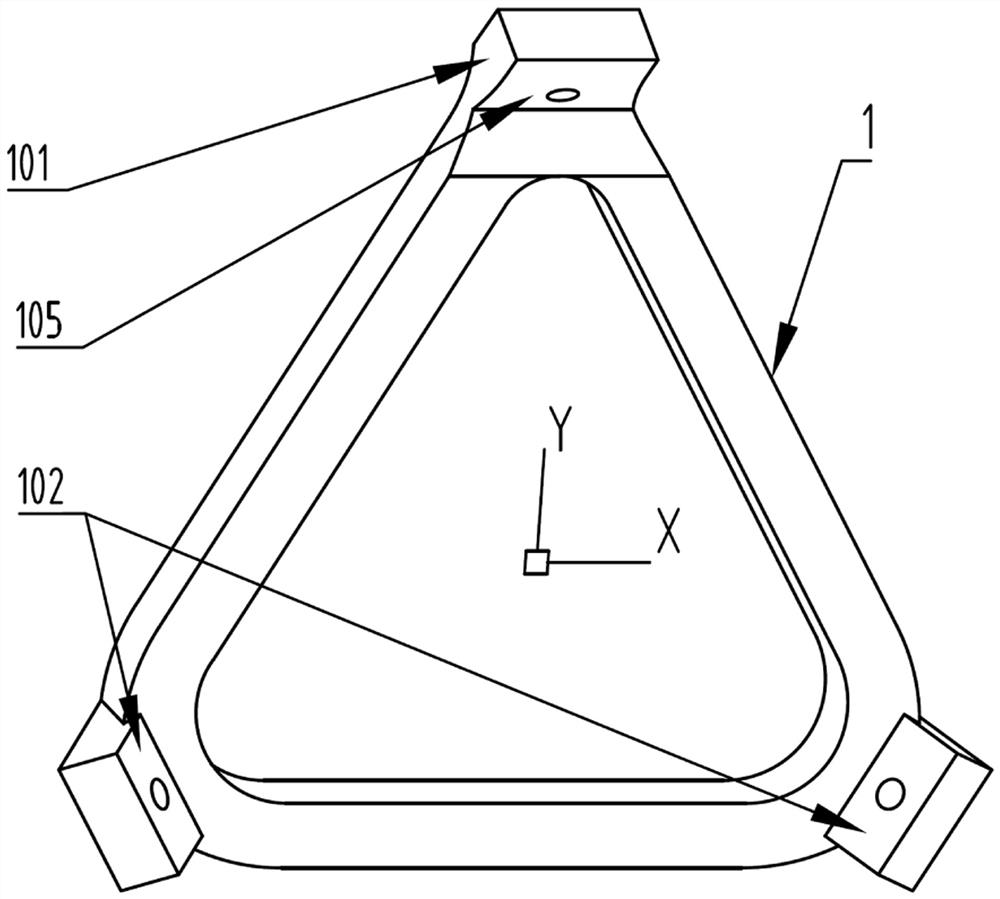

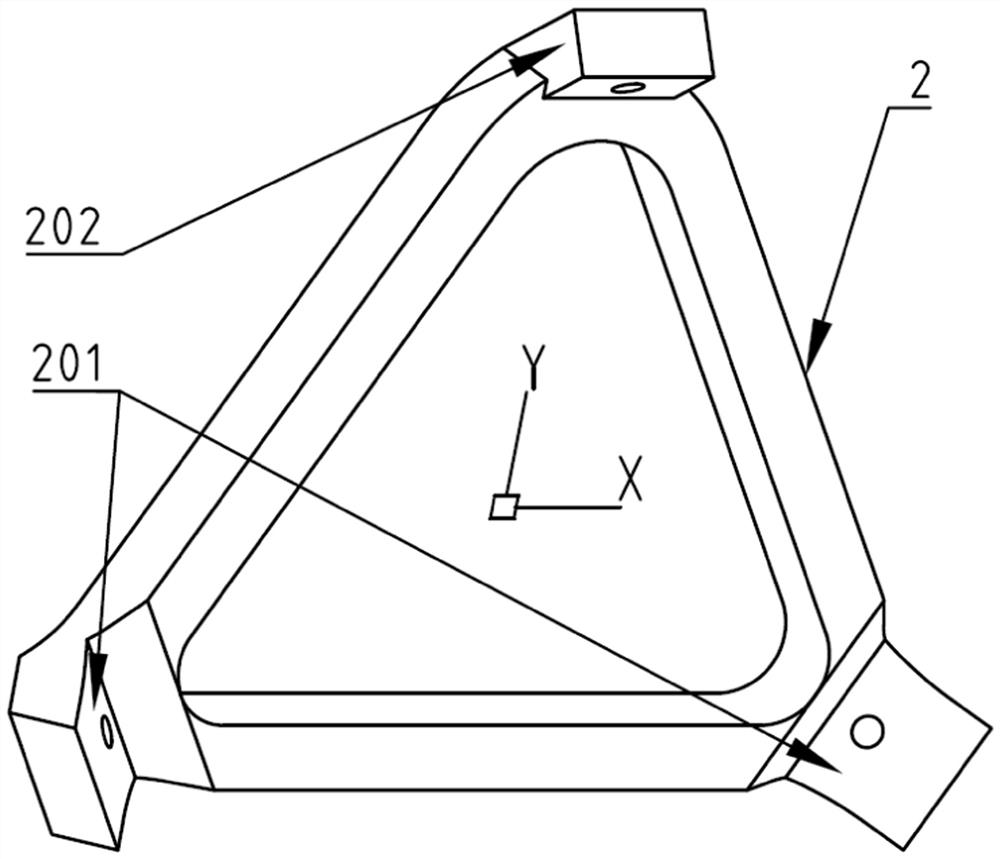

[0032] see Figure 1-10 , The assembled periodic octahedral truss lattice structure provided by the present invention is composed of two Type I connecting blocks 1, two Type II connecting blocks 2 and bolt groups.

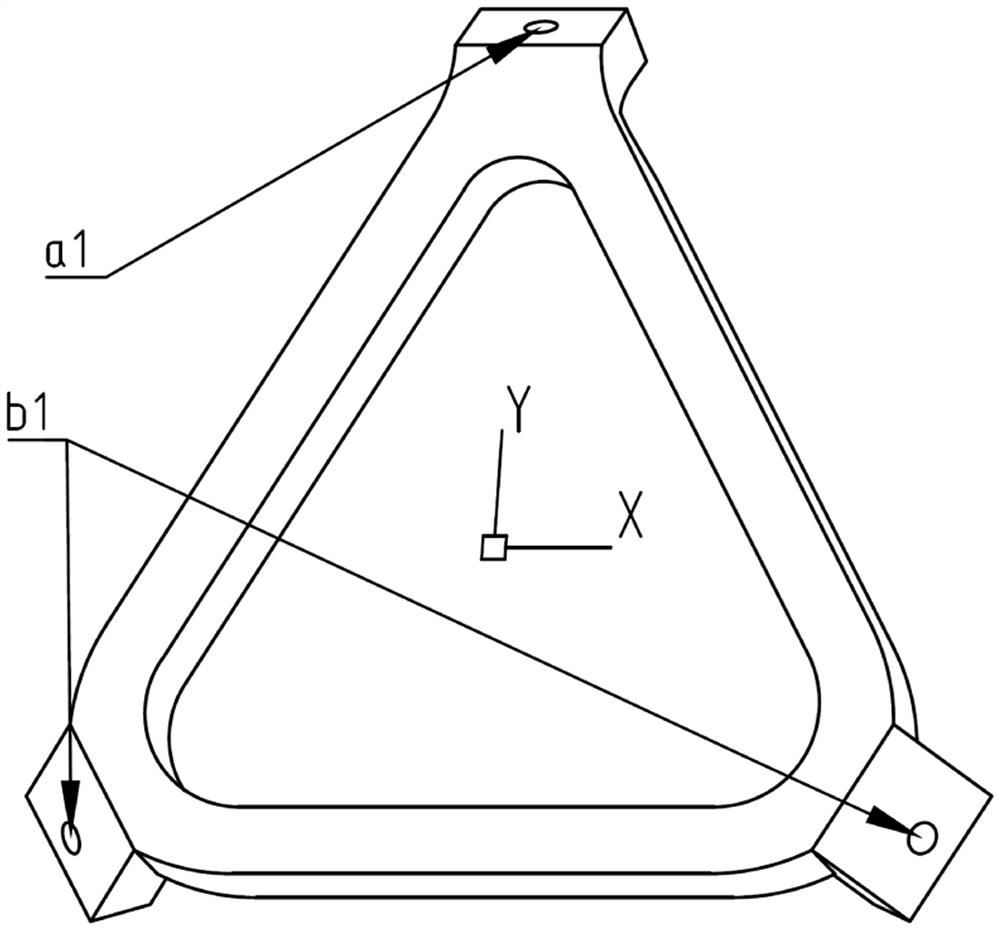

[0033]Further, the inner sides of the Type I connection block 1 and the Type II connection block 2 are closed regular triangles with rounded corners that are symmetrical about the Y axis; wherein the inner contour of the Type I connection block 1 has two radii R1 and 1 rounded corner with a radius of R2, 2 sockets and 1 mounting head with a certain thickness on the outside; 1 rounded corner with a radius of R1 and 2 rounded corners with a radius of R2 on the outside of the Type II connection block, Correspondingly, it has 2 installation heads and 1 socket head, and has a certain thickness, take

[0034] Further, in this embodiment, the overall maximum size of the unit cell is L, the radius of the large fillet in the rounded triangles of the inner contours of the...

Embodiment 2

[0039] see Figure 9-11 , in order to improve the connection strength of the periodic octahedral truss lattice structure, the connection mode of the octahedral truss lattice unit cells can be adjusted.

[0040] Specifically, as described in Example 1, multiple octahedral truss lattice unit cells are combined and assembled, and adjacent unit cells are interconnected by long bolt groups to form a duplex unit cell group.

[0041] Further, using the ideas of point-to-line, line-to-surface, and surface-to-body, the truss lattice unit cell space structure 8 is gradually formed, which helps to improve the strength and stability of the porous structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com