Low-noise power capacitor based on damping steel plate

A technology for power capacitors and capacitors, which is applied to fixed capacitor casings/packages, sounding devices, and fixed capacitor components, etc. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is described in further detail:

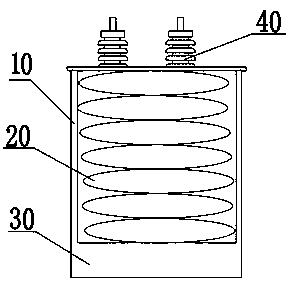

[0015] The low-noise power capacitor of the present invention comprises a capacitor case 10, a capacitor core 20, a sound insulation chamber 30 and a terminal sheath 40, the capacitor core 20 is arranged inside the capacitor case 10; the sound insulation chamber 30 is composed of two inner and outer layers A closed cavity structure composed of steel plates, the sound insulation cavity 30 is set at the bottom of the capacitor shell 10, the closed cavity structure is fixed on the bottom of the capacitor by welding, and a damping material is provided between the outer steel plate and the inner steel plate to form a three-dimensional structure. Layer closed cavity structure; the terminal sheath 40 is disposed on the top of the capacitor case 10 . The inside of the closed cavity is air. The thickness of the air layer inside the closed cavity is 25 mm. The steel plate is a stainless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com