Powder coating leveling agent and preparation method and application thereof

A powder coating and leveling agent technology, applied in the direction of coating, etc., can solve the problem of slow leveling speed of acrylic leveling agents, complicated preparation methods of silicone leveling agents, low surface tension of silicone leveling agents, etc. problem, to achieve the effect of low price, good heat resistance and strong hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

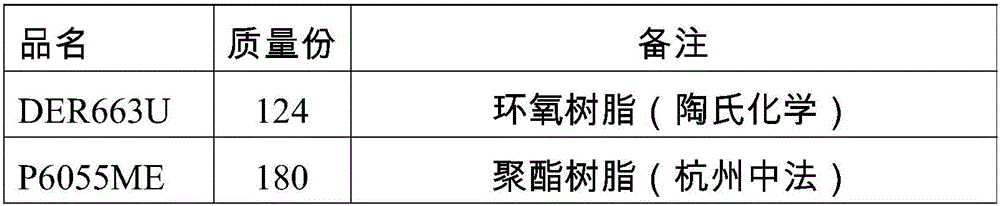

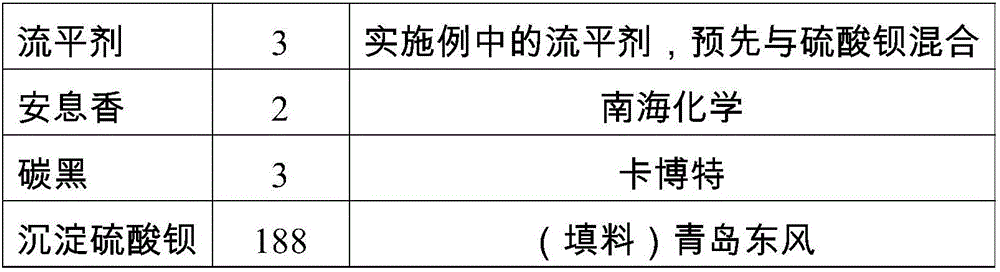

Examples

Embodiment 1

[0029] The invention provides a powder coating leveling agent and a preparation method thereof: add 400g xylene in a 2000ml four-necked flask with a stirring, thermometer and reflux device; mix 360g butyl acrylate, 40g soybean oil, and 10.2gBPO initiator , to completely dissolve the BPO, put it into the dropping funnel; heat the xylene to 105°C, start dropping, control the reaction temperature at 105-110°C, after 1.5h dropwise addition, continue to keep warm for 1.5h; remove the solvent in vacuo, and get Pale yellow transparent liquid, sample number 1#.

Embodiment 2

[0031] The invention provides a powder coating leveling agent and a preparation method thereof: add 400g xylene in a 2000ml four-neck flask with a stirring, thermometer and reflux device; mix 340g butyl acrylate, 60g soybean oil, and 9.2g BPO initiator Mix to dissolve the BPO completely, put it into the dropping funnel; heat the xylene to 105°C, start to add dropwise, control the reaction temperature to 105-110°C, complete the dropwise addition in 1.5h, keep it warm for 1.5h; remove the solvent in vacuum to get Pale yellow transparent liquid, sample number 2#.

Embodiment 3

[0033] The invention provides a powder coating leveling agent and a preparation method thereof: add 400g xylene in a 2000ml four-neck flask with a stirring, thermometer and reflux device; mix 300g butyl acrylate, 100g soybean oil, and 9.2g BPO initiator Mix to dissolve the BPO completely, put it into the dropping funnel; heat the xylene to 105°C, start to add dropwise, control the reaction temperature to 105-110°C, complete the dropwise addition in 1.5h, keep it warm for 1.5h; remove the solvent in vacuum to get Pale yellow transparent liquid, sample number 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com