Aluminum alloy composite plate

An aluminum alloy plate and aluminum alloy technology, which is applied in the field of aluminum alloy, can solve the problems of honeycomb plate difficult to shape, high production cost, divergent peeling, etc., and achieve the effect of strong binding force, low production cost and less aluminum consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and effect of the present application more clear and definite, the present application will be further described in detail below with reference to the accompanying drawings and examples.

[0019] The present application provides an aluminum alloy composite panel, which can be used in the construction industry as a curtain wall material and an interior decoration material, and can also be used in fields such as caravans, shelters, vans, buses, and containers. It has the advantages of high strength, lighter and thinner, can reduce light pollution, fire prevention, and low energy consumption. It can also be used as a supporting material in other industries. The aluminum alloy composite board is light in weight, high in strength, capable of carrying heavy objects, and is not easily deformed.

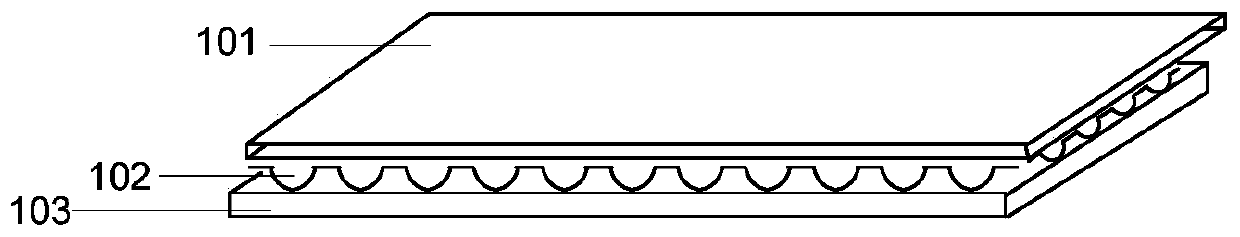

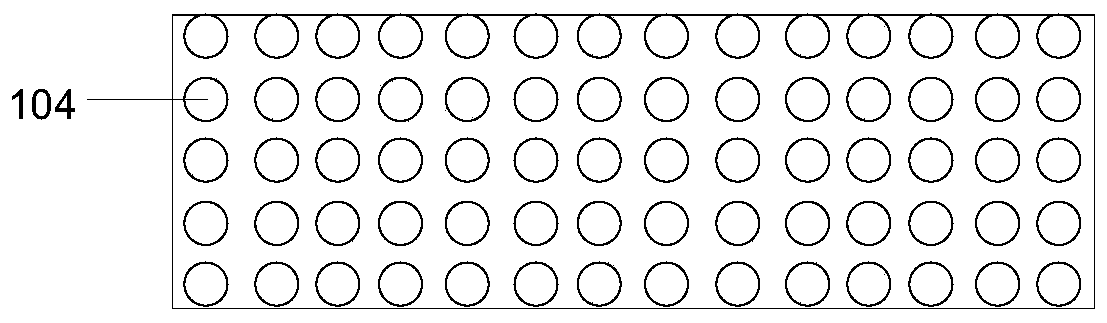

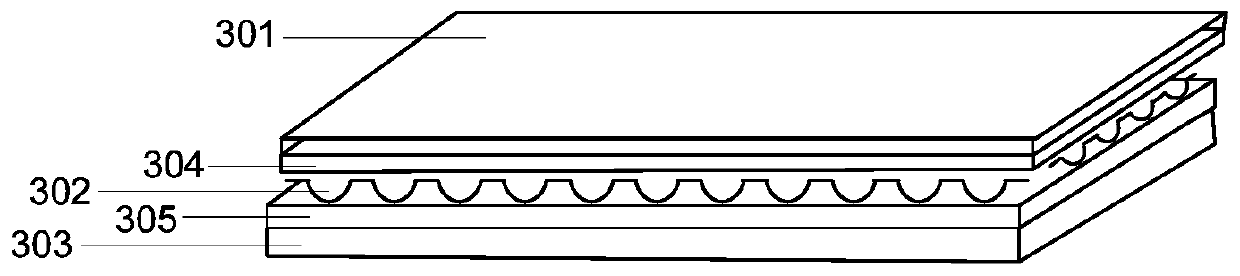

[0020] see figure 1 and figure 2 , figure 1 It is a structural schematic diagram of the first embodiment of the aluminum alloy com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com