Method for recycling waste residue in manganese industry production

A technology of waste residue and filter residue, applied in application, agriculture, process efficiency improvement and other directions, can solve the problems of using many auxiliary materials and mechanical equipment, large production area, long process route, etc., to achieve no waste residue discharge and increase heavy metal content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

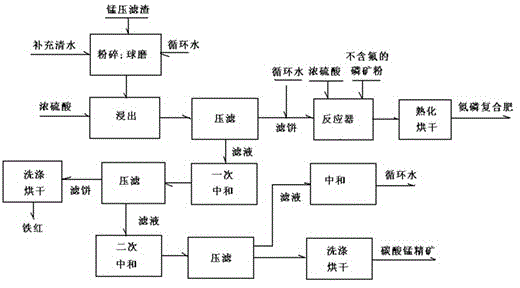

Method used

Image

Examples

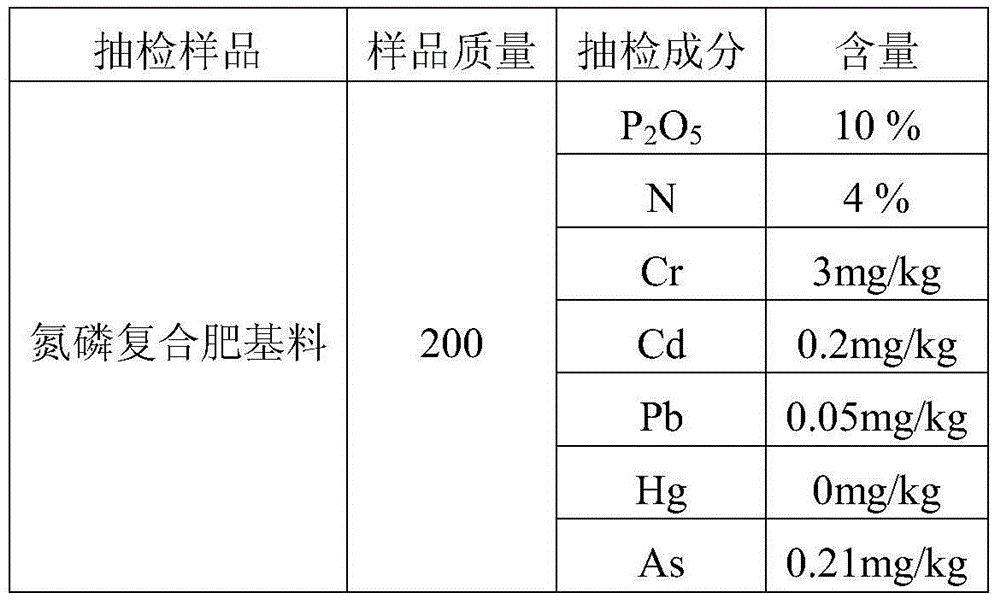

Embodiment 1

[0030] 1. Weigh 1000g of leached filter press residue and 8L of clean water, put them into a pulverizer to pulverize them into a pulp, and pass through a 100-mesh sieve. Finally, pass through a 100-mesh sieve and add the compound mixing tank together, start the mixer, and stir at a stirring speed of 65 rpm.

[0031] 2. Measure 98% H2SO4500ml, add it into the mixing tank while stirring, continue stirring for about 4 hours, measure the pH value to 1.5, and stop stirring.

[0032] 3. Filtrate for solid-liquid separation, put the filter residue away for future use, put the filtrate into the neutralization and hydrolysis mixing tank, start the mixer, and stir at a stirring speed of 65 rpm.

[0033] 4. Slowly add NH4HCO3 powder while stirring, neutralize once, and test the pH value of the solution. When the pH is 4, stop adding NH4HCO3, continue stirring until no bubbles are generated, and stop stirring.

[0034] 5. Filtrate solid-liquid separation, put the filtrate into the neutra...

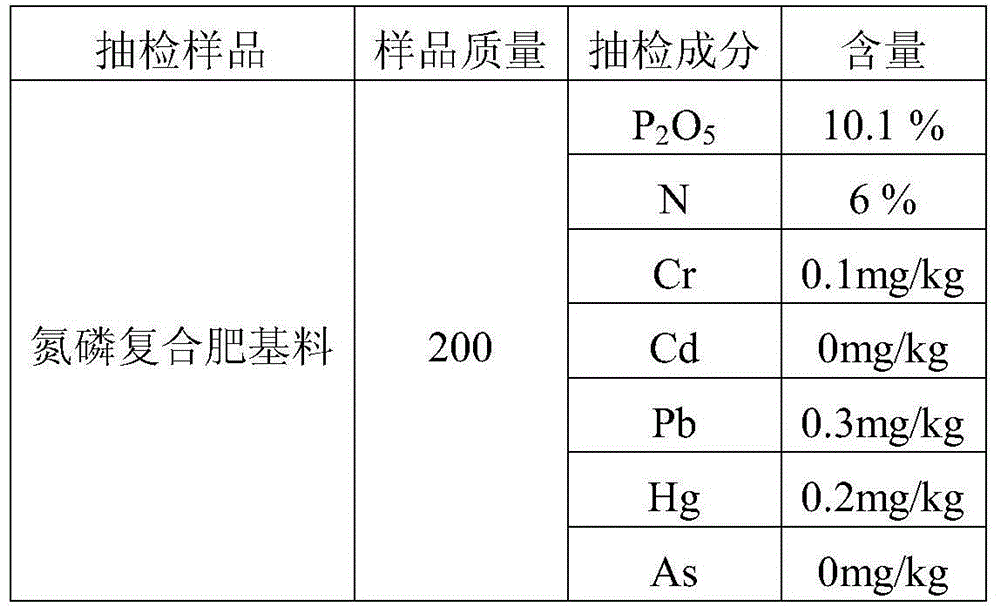

Embodiment 2

[0049] 1. Weigh 1000g of the leached filter press residue, measure 2 / 3 of the water in the "eighth item" circulating bucket in the example (1), put it into a pulverizer to pulverize it into a pulp, and pass it through a 100-mesh sieve, and the undersieve enters The compound mixing tank, the sieved material enters the small grinder, adds the remaining water in the "eighth item" circulating bucket of the previous example to grind together, and then passes through the 100-mesh sieve and adds the compound mixing tank together, and starts the mixer to stir at a stirring speed of 65 rpm .

[0050] 2. Measure 98% H2SO4500ml, add it into the compound mixing tank while stirring, continue stirring for 4 hours, measure the pH value to 1.0, and stop stirring.

[0051] 3. Filtration solid-liquid separation: put the filter residue away for use, put the filtrate into the neutralization hydrolysis mixing tank, start the mixer, and stir at a stirring speed of 65 rpm.

[0052] 4. Slowly add (N...

Embodiment 3

[0069] 1. Weigh 1000g of the leached filter press residue, measure 2 / 3 of the water in the circulating bucket of "Example (2) Item 8", put it into a pulverizer to pulverize it into a pulp, and pass it through a 100-mesh sieve, and the under-sieve enters In the compounding mixing tank, the supernatant and the remaining water in the "Example (2) Item 8" circulating water tank are added into a small grinder for grinding, and then all pass through a 100 mesh screen and added to the compounding mixing tank. Start the mixer to stir at a stirring speed of 65 rpm.

[0070] 2. Measure 98% H2SO4, add it into the compound mixing tank while stirring, continue stirring for 4 hours, measure the pH value to 0.5, and stop stirring.

[0071] 3. Filtrate for solid-liquid separation, put the filter residue aside for use, put the filtrate into the neutralization and hydrolysis mixing tank, and start the mixer to stir at a stirring speed of 65 rpm.

[0072] 4. Slowly add ammonia water containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com