Cyclic utilization method of desulphurization waste water

A technology for desulfurization wastewater and concentrated water, which is applied in chemical instruments and methods, gaseous effluent wastewater treatment, water/sewage multi-stage treatment, etc. It can solve the problems of heavy metal ions without self-purification and biodegradability, animal and plant life activities hazards, etc. , to achieve the effects of increasing salt content, reducing material and energy consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

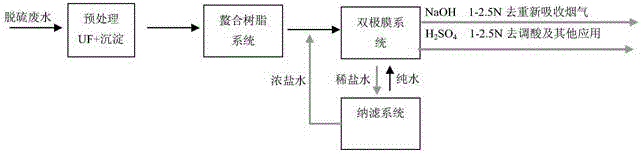

[0021] With reference to the accompanying drawings, the desulfurization wastewater entering the process of the present invention is first processed in step (1): the desulfurization wastewater is treated with precipitation, chelating resin and ultrafiltration system, large particle substances are removed by precipitation, and ultrafiltration (UF) To remove small suspended solids and colloids, the desulfurization wastewater first enters the sedimentation tank for precipitation, and the effluent enters the ultrafiltration system. The ultrafiltration system produces water, which is treated with chelating resin and then enters step (2). The concentrated water enters the sedimentation tank for precipitation. . In step (1), the recovery rate of ultrafiltration is controlled above 95%, and the removal rate of total suspended solids TSS reaches above 98%, <1mg / L; after treatment with chelating resin, heavy metal ions <1mg / L . The above parameters can also be adjusted according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com