Cohesive action nutrient source SRB sewage sludge immobilization particle, production and uses in treating heavy metal wastewater thereof

A nutrient source and heavy metal technology, applied in the field of environmental engineering, can solve the problems of difficult utilization of organic carbon sources, secondary pollution of organic matter, high COD of effluent, and achieve the effect of avoiding direct poisoning, high treatment efficiency and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Step 1, after washing and removing impurities from the urban sewage treatment plant, put the remaining sludge into the sludge bottle, and add the culture medium (component KH 2 PO 4 0.5g / L, NH 4 Cl 1.0g / L, MgSO 4 ·7H 2 O 0.06g / L, CaSO 4 1.0g / L, FeSO 4 ·7H 2 O 0.01g / L, Na 2 SO 4 4.5g / L, CaCl 2 ·H 2 O 0.06g / L, sodium lactate 3.5g / L), after sealing, pass nitrogen for 30 minutes, put the sludge bottle into a biochemical incubator for cultivation at 30°C, replace part of the medium every day, pass nitrogen, and the cultivation is completed in 7-10 days , to get SRB sludge.

[0050] Step 2: Take out the SRB sludge mixture, and centrifuge at 3000r / min for 10min to obtain SRB sludge; weigh a certain amount of polyvinyl alcohol (PVA) and place it in deionized water for heating and dissolving. After cooling to 40°C, the SRB Add sludge and activated carbon, stir evenly, and its concentration (wt%) is about 30% SRB sludge, 9% PVA, 5% activated carbon, and then use a p...

Embodiment 2

[0054] The comparison of the effects of different SRB methods in treating zinc-containing wastewater is shown in Table 1. The cohesive nutrient source SRB pellets are prepared in the same way as in Example 1; the free SRB sludge is obtained from step 1 in Example 1; the SRB pellets are obtained from step 2 in Example 1, and the pellets are sterilized in a sterilizing pot After that, a blank pellet is obtained. The data in the table are the statistical results after multiple experiments. The data in the table shows that the removal of heavy metal ions and the reduction of sulfate radical by cohesive nutrient source SRB pellets reach 99% and 95% respectively. The COD value of the effluent is also controlled below the national standard of 120mg / L (GB 8978-1996). The amount of sodium lactate adsorbed inside the cohesive nutrient source SRB pellets is 62mg / g (sodium lactate / ball), which is equivalent to 2907.8mg / L of COD. If an external method is used, the same amount of sodium l...

Embodiment 3

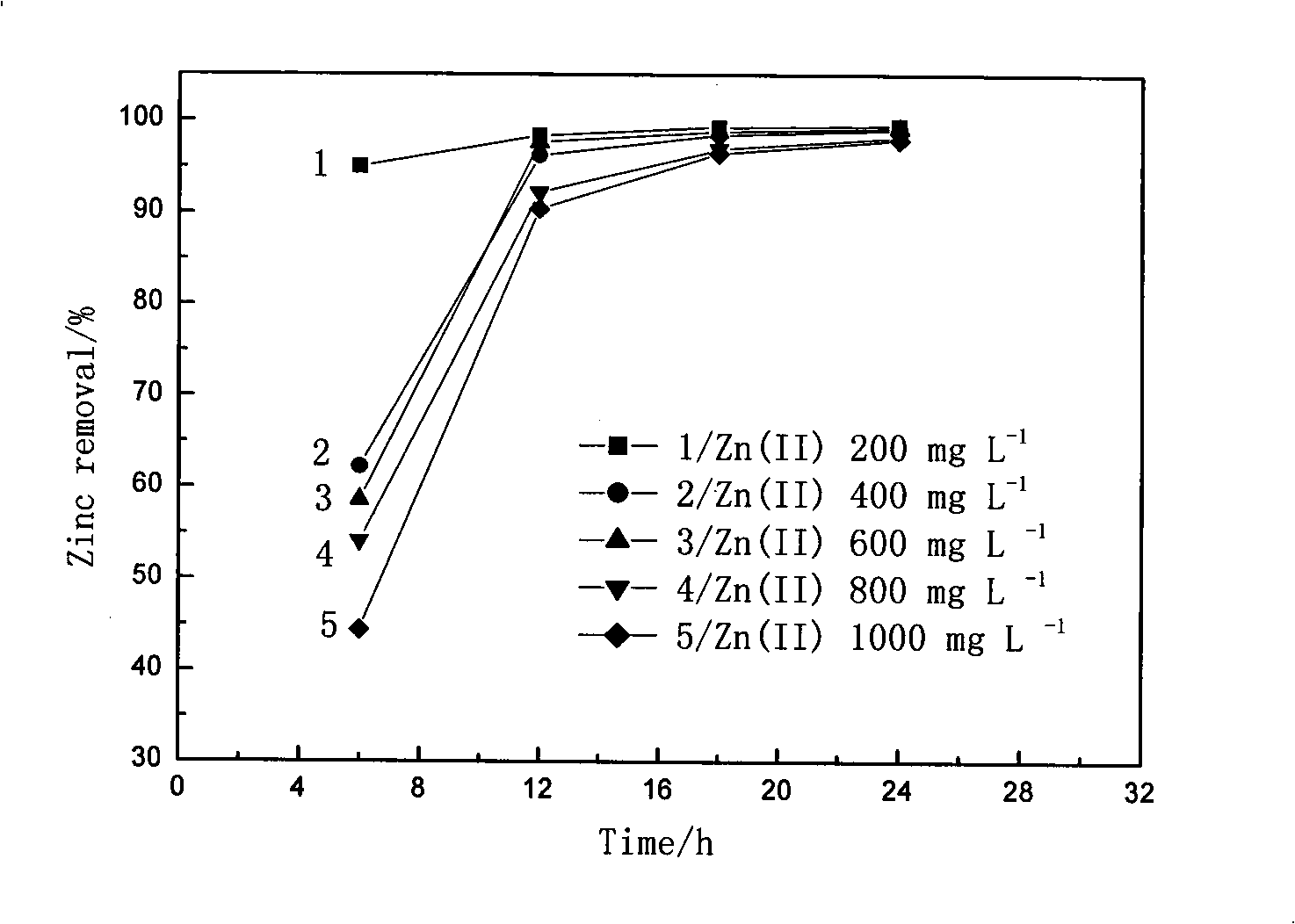

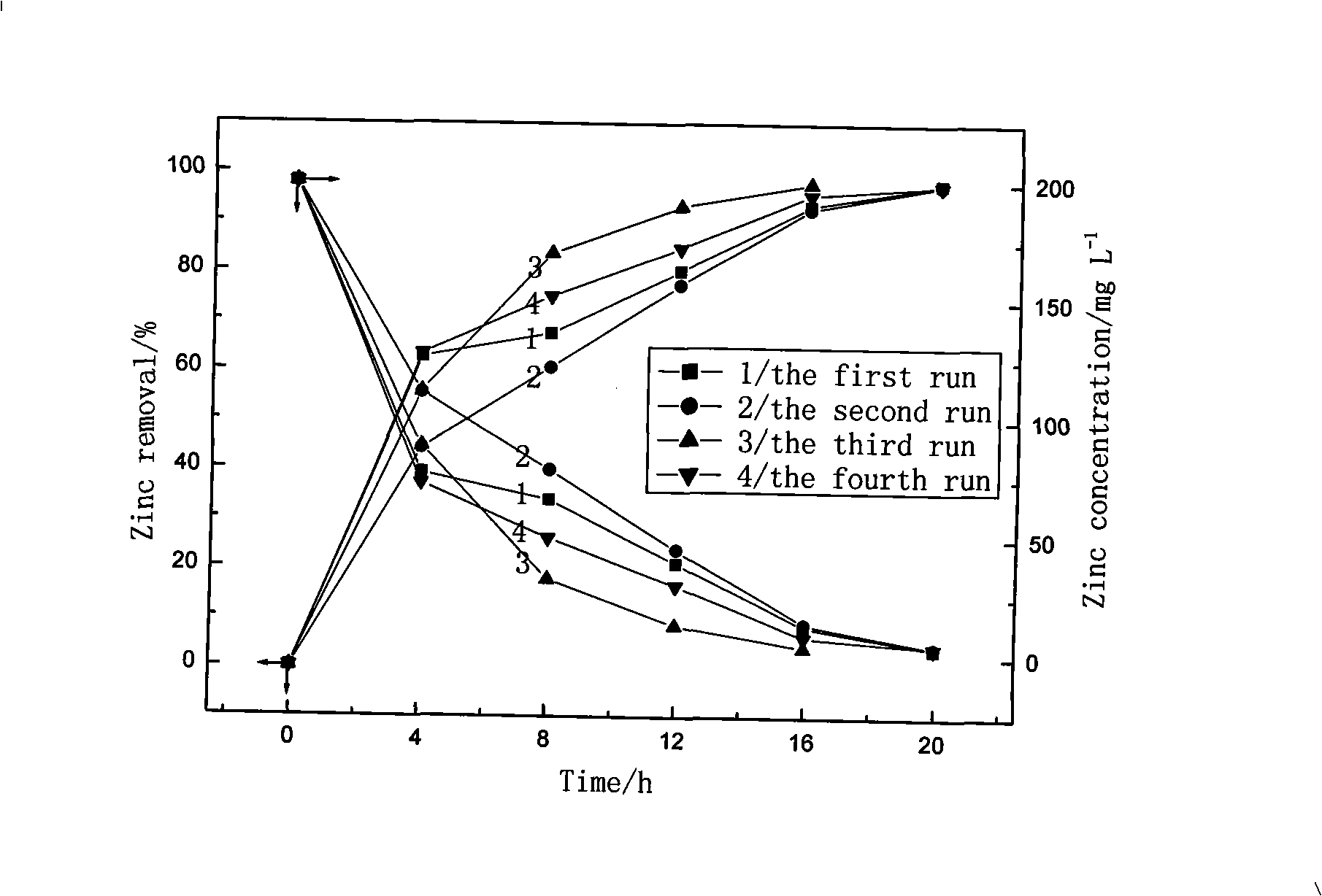

[0058] Prepare cohesive nutrient source SRB immobilized pellets according to Example 1, under anaerobic conditions, 30°C, shaking rate 100rpm, treat 200mg / L zinc-containing wastewater, after the sodium lactate carbon source in the pellets is exhausted, wash, and follow the implementation In example 1, step 3 regenerates nutrient source, and the effect of treating zinc-containing wastewater four times is as follows image 3 shown. Four times of regeneration, the zinc removal rate exceeds 99% each time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com