Physical ore dressing removal method for heavy metals in copper tailing

A technology of heavy metal and copper tailings, which is applied in the field of mine ecological environment and tailings resource reuse, can solve the problems of high energy consumption, high cost, heavy metal hazards, etc., and achieve the effect of improving economic benefits and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

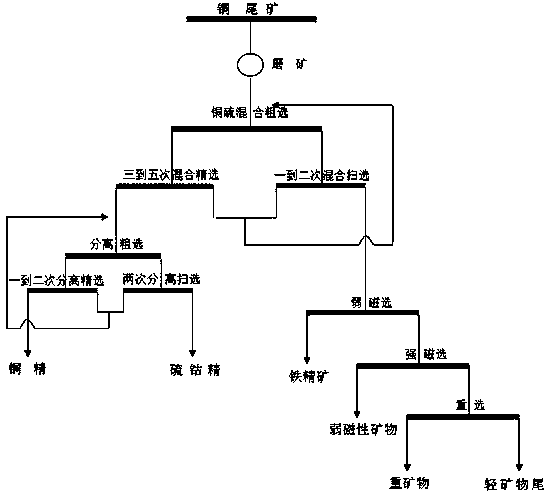

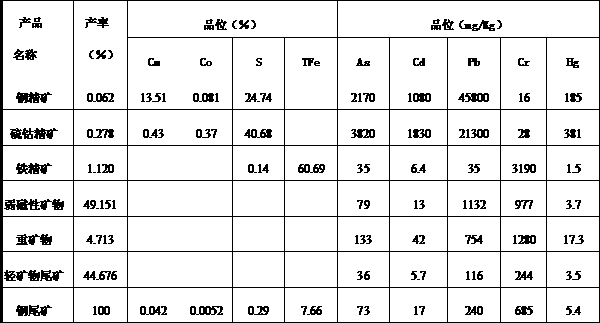

[0032] The raw material is the tailings newly discharged from a large-scale porphyry copper ore dressing plant in China, of which: the copper tailings contain 0.040% copper, 0.29% sulfur, 0.012% cobalt, 7.66% iron, arsenic, Cadmium, lead, chromium, mercury content are respectively 0.0073%, 0.0017%, 0.024%, 0.0685%, 0.00054%, utilize technology of the present invention, carry out following steps, as figure 1 :

[0033] A. Grinding step: Put the copper ore tailings into the ball mill for closed-circuit grinding operation, and grind to -0.074mm content of 76.8%;

[0034]B. Mixed flotation step of sulfide ore: Add the ground copper tailings to the flotation equipment, add soda ash to adjust the pH value of the slurry to 8-9, use butyl xanthate and Z-200 as collectors, and terpineol oil As a foaming agent, a closed-circuit flotation operation of roughing once, twice sweeping, and five times of beneficiation is carried out, and an appropriate amount of water glass is added as a dis...

Embodiment 2

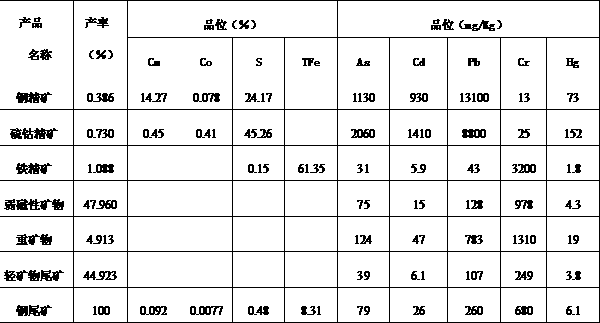

[0042] Copper beneficiation tailings from a large-scale porphyry-type copper mine tailings pond in China are used as raw materials, of which: copper tailings contain 0.092% copper, 0.48% sulfur, 0.0077% cobalt, 8.31% iron, arsenic, cadmium, lead, Chromium, mercury content are respectively 0.0079%, 0.0018%, 0.026%, 0.0680%, 0.00061%, utilize technology of the present invention, carry out following steps, as figure 1 :

[0043] A. Grinding step: put the copper ore tailings into the ball mill for closed-circuit grinding operation, and grind to -0.074mm content of 71.5%;

[0044] B. Mixed flotation step of sulfide ore: Add the ground copper tailings to the flotation equipment, add soda ash to adjust the pH value of the slurry to 8-9, use butyl xanthate and Z-200 as collectors, and terpineol oil As a foaming agent, a closed-circuit flotation operation of roughing once, twice sweeping, and three times of beneficiation is carried out, and an appropriate amount of water glass is adde...

Embodiment 3

[0052] As another preferred embodiment of the present application, refer to the attached figure 1 , this example discloses:

[0053] A material dressing and removal method for heavy metals in copper tailings, comprising the following steps:

[0054] A. Grinding step: add copper ore tailings into the grinding equipment for closed-circuit grinding operation, and grind to -0.074mm content of 65%;

[0055] B. Mixed flotation step of sulfide ore: add the copper tailings ground in the above grinding step to the flotation equipment, add soda ash to adjust the pH value of the pulp to 8-9, and use butyl xanthate and Z-200 as the collection agent, pine oil as a foaming agent, a closed-circuit flotation operation of roughing, two sweeps, and four beneficiations; water glass is added as a dispersant in the beneficiation operation to obtain copper-sulfur mixed concentrate and flotation Dressing tailings: butyl xanthate roughing 50g / ton, 5g / ton each for the first and second sweeping, Z-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com