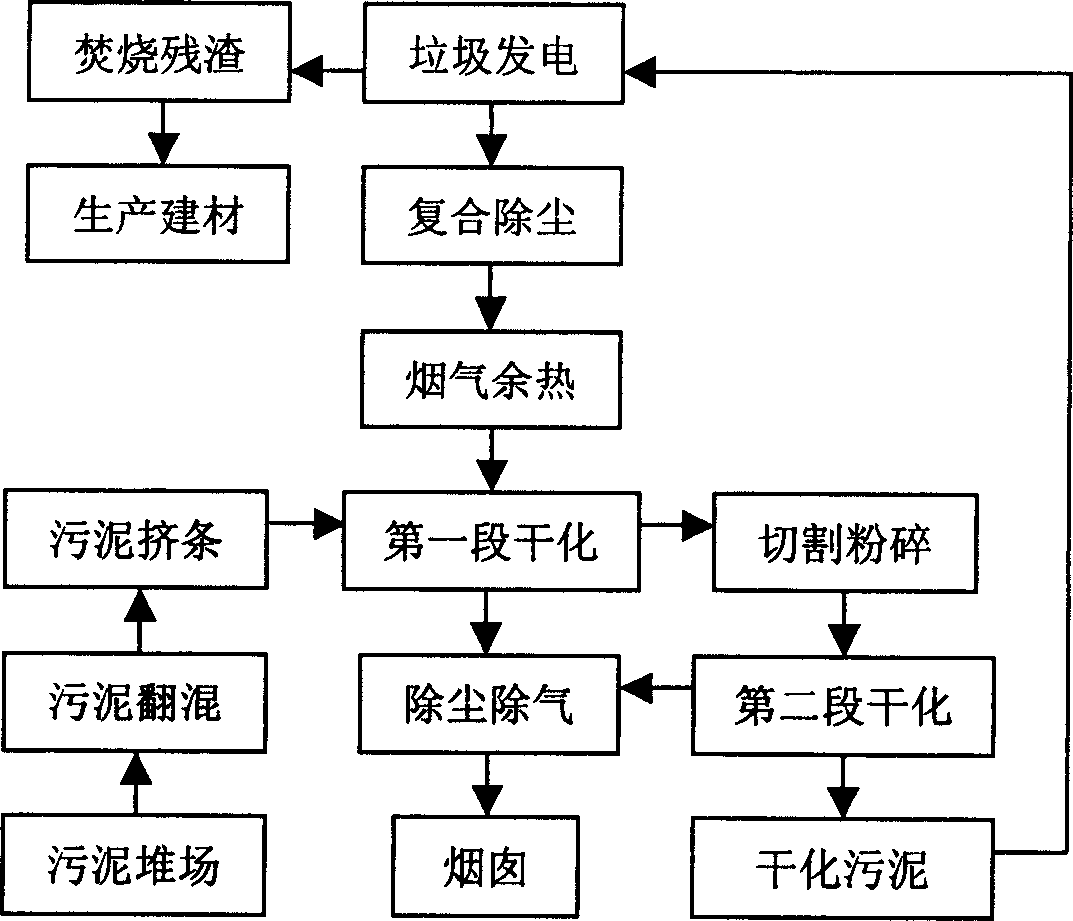

Method for integrating drying sludge using remaining heat of flume from power plant by rubbish and electricity generation using sludge

A technology for drying sludge and flue gas waste heat, which is applied in the directions of oxidation treatment sludge, dehydration/drying/thickening sludge treatment, sludge treatment through temperature control, etc., which can solve the problems of high cost and large amount, and achieve significant social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1, Jiangsu Wuxi Waste-to-energy Plant, two existing waste incinerators are put into operation, and the amount of flue gas produced by each incinerator is 150,000m3 3 / hour, the waste heat temperature of the flue gas is about 150°C, and this technology is used to process 100 tons of urban sludge (with a moisture content of about 75%) per day. First, the sludge is pretreated in the stacking yard, part of the water is naturally evaporated, and the sludge is homogenized, and then the sludge is extruded into a column with a diameter of 8 mm through the extruder, and sent to the first rotary Drying kiln, use 100000m 3 The amount of flue gas per hour is carried out in the first stage of drying to reduce the moisture content of the sludge by 25%. After the sludge leaves the kiln, it passes through the cold conveyor belt and enters the second rotary drying kiln. 3 The amount of flue gas per hour, the second stage of drying reduces the moisture content of the sludge by 3...

Embodiment 2

[0028] Example 2, Zhejiang Garbage Power Plant, the amount of flue gas produced by waste incineration power generation is 130000m3 3 / hour, the waste heat temperature of the flue gas is about 130°C, and this technology can process 50 tons of urban sludge (with a moisture content of about 75%) per day. First, the sludge is pretreated in the stacking yard, part of the water is naturally evaporated, and the sludge is homogenized, and then the sludge is extruded into a column with a diameter of 8 mm through the extruder, and sent to the first rotary Drying kiln, with 80000m 3 The amount of flue gas per hour is dried in the first stage to reduce the moisture content of the sludge by 20%. After the sludge leaves the kiln, it passes through the cold conveyor belt and enters the second rotary drying kiln. 3 The amount of flue gas per hour, the second stage of drying reduces the moisture content of the sludge by 33%, and the sludge after the second stage of flue gas waste heat drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com