Modified trash storing pit landfill leachate collecting system

A technology for landfill leachate and a collection system, which is applied in the field of effective collection systems for landfill leachate in landfill storage pits, can solve problems such as failure, hidden dangers of structure safety and durability of landfill pits, clogging of landfill leachate collection systems, etc., and achieves improved efficiency. , Good energy utilization and environmental protection, the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

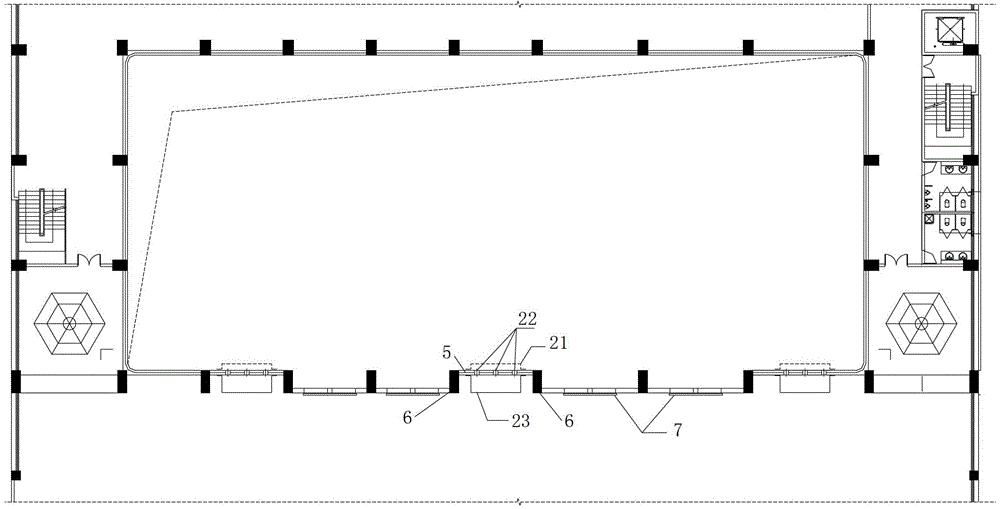

[0021] The present invention is an improved garbage leachate collection system for garbage storage pits, which includes a horizontal collection system 1, a vertical collection system 2 and a collection pool 3.

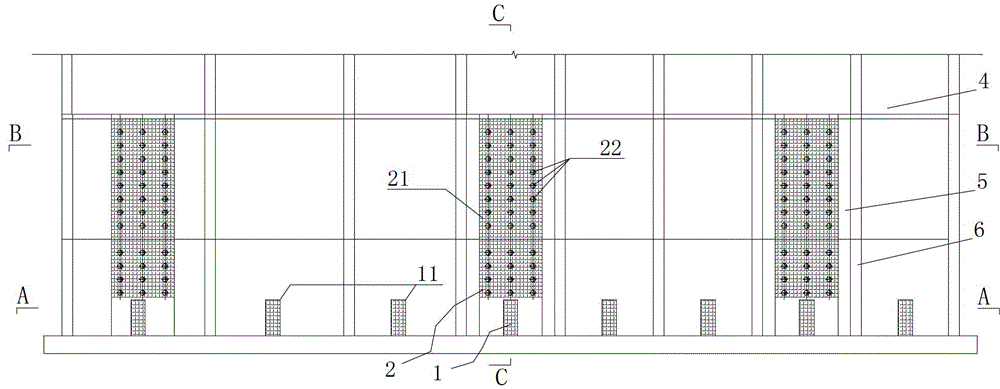

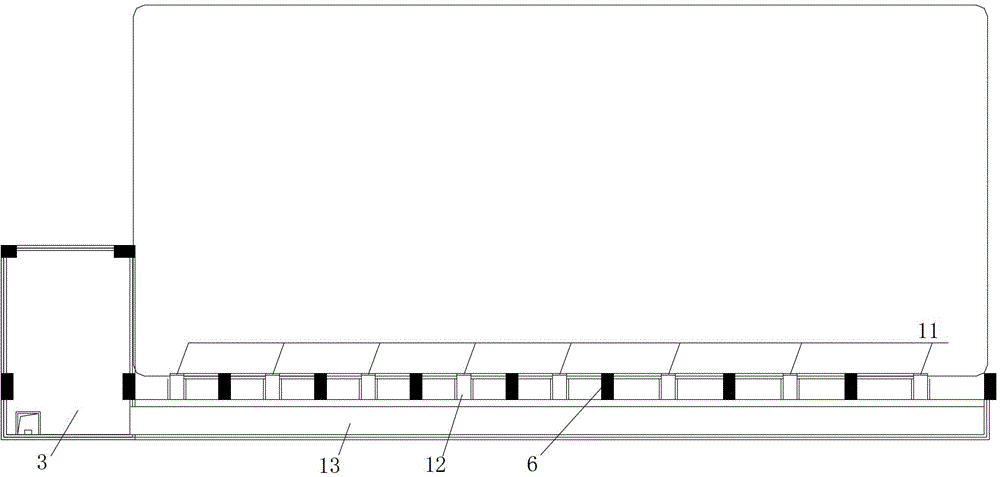

[0022] Such as figure 1 , figure 2 As shown, the horizontal collection system 1 includes a plurality of collection grids 11 arranged in the horizontal direction at the bottom of the side wall of the garbage storage pit, a garbage leachate collection pit 13, and a leachate collection ditch 12.

[0023] Such as figure 1 , image 3 , Figure 4 As shown, the vertical collection system 2 is vertically arranged above the horizontal collection system 1 to the bottom of the discharge platform 4 of the garbage storage pit. The vertical collection system 2 is installed on the wall 5 between columns of the garbage storage pit. The vertical collection system 2 includes a drain hole 22 penetrating the side wall of the garbage pit, a movable grille 21 that can move up and down and is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com