Leachate suspended matter removal device for garbage power plant

A technology for leachate and power plants, which is applied in the field of leachate suspended solids removal devices in waste-to-energy plants, can solve the problems of high manufacturing requirements for mechanical grids, poor sanitation conditions, and low risk factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

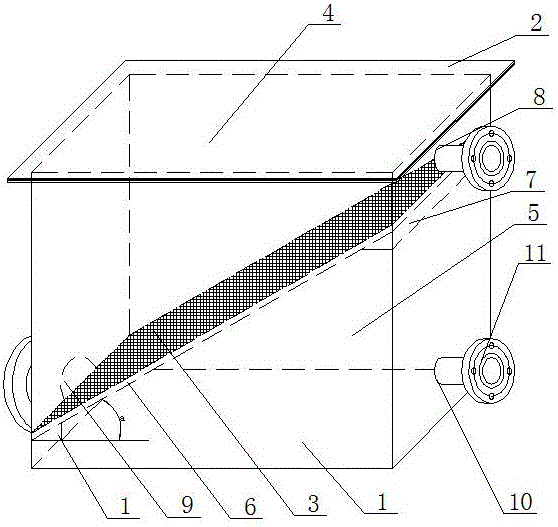

[0012] Such as figure 1 As shown, the present invention includes a box body 1 and a box cover 2 connected to the upper end of the box body 1, and opening the box cover 2 just allows maintenance and thorough cleaning of the inside of the box body.

[0013] The box 1 is provided with an obliquely arranged screen 3 to divide the box 1 into an upper cavity 4 and a lower cavity 5. The screen 3 is made of 304 stainless steel, and the inclination angle of the screen 3 is a, a=30° , The mesh number of screen cloth 3 is 7 meshes.

[0014] The screen 3 is supported in the box body 1 by a square grid plate 6, the two ends of the box body 1 are respectively equipped with support members 7, the two ends of the square grid plate 6 are respectively supported on the corresponding support members 7, and the screen cloth 3 is supported on On the square grid plate 6, the screen cloth 3 and the square grid plate 6 can be freely taken out.

[0015] The upper end of the upper chamber 4 located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com