Power plant, method and system for controlling garbage incineration power plant equipment based on DCS (Distributed Control System)

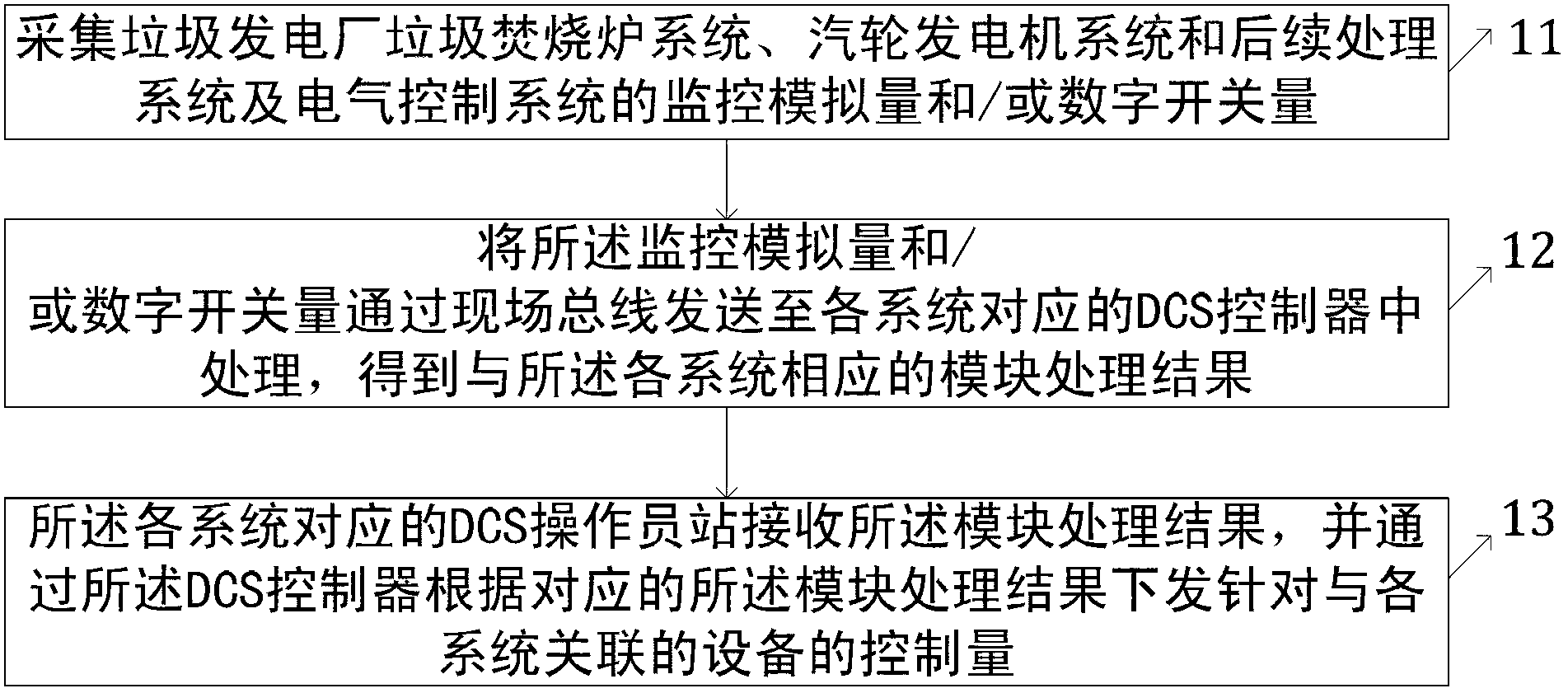

A technology of DCS controller and control method, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., and can solve problems such as inconvenient maintenance, high communication pressure, and inability to control orderly equipment running in parallel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

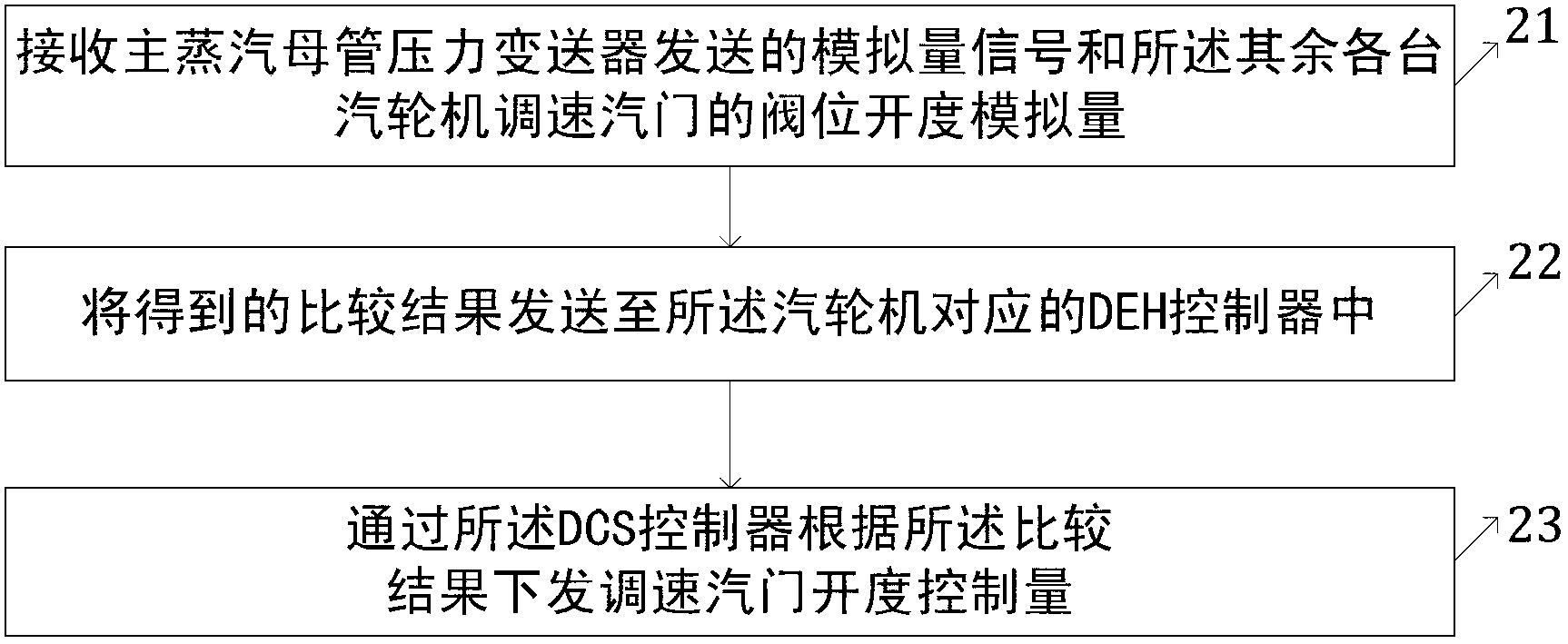

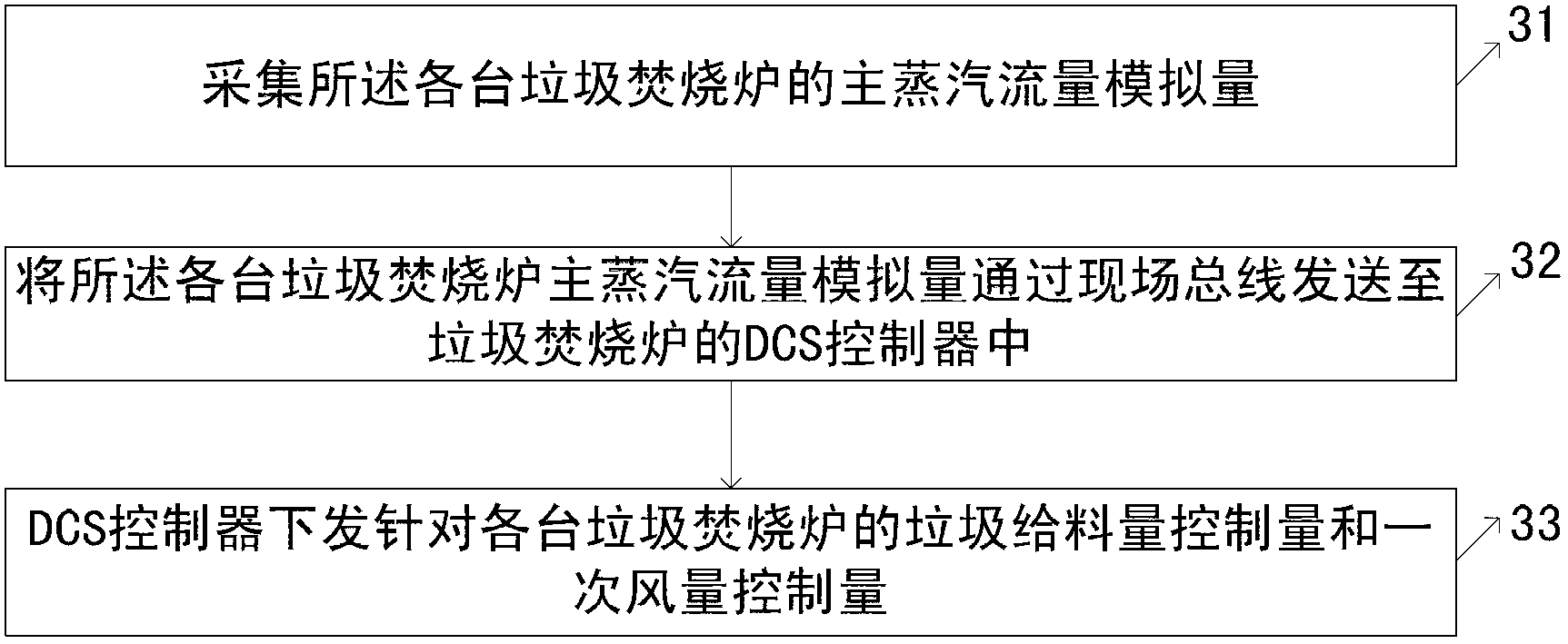

Embodiment Construction

[0091] For reference and clarity, technical terms, abbreviations or abbreviations used hereinafter are summarized as follows:

[0092] DCS: Distributed Control System, distributed control system;

[0093] PLC: Programmable Logic Controller Programmable Logic Controller;

[0094] DEH: Digital Electric Hydraulic Control System, steam turbine digital electro-hydraulic control system; in the present invention, the function of DEH is realized by the same set of DCS system;

[0095] Profibus DP: Profibus DP is an international, open, field bus standard independent of equipment manufacturers; Profibus DP transmission speed can be selected in the range of 9.6Kbps ~ 12Mbps and when the fieldbus system starts, all Devices on the fieldbus should be set to the same speed.

[0096] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com