Integrated system of using garbage power plant smoke residual heat to dry sludge and sludge power generation

A flue gas waste heat and sludge drying technology, which is applied in oxidation treatment of sludge, dehydration/drying/thickened sludge treatment, incinerator, etc., can solve the problems of high cost, achieve emission reduction, and significant social and environmental benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

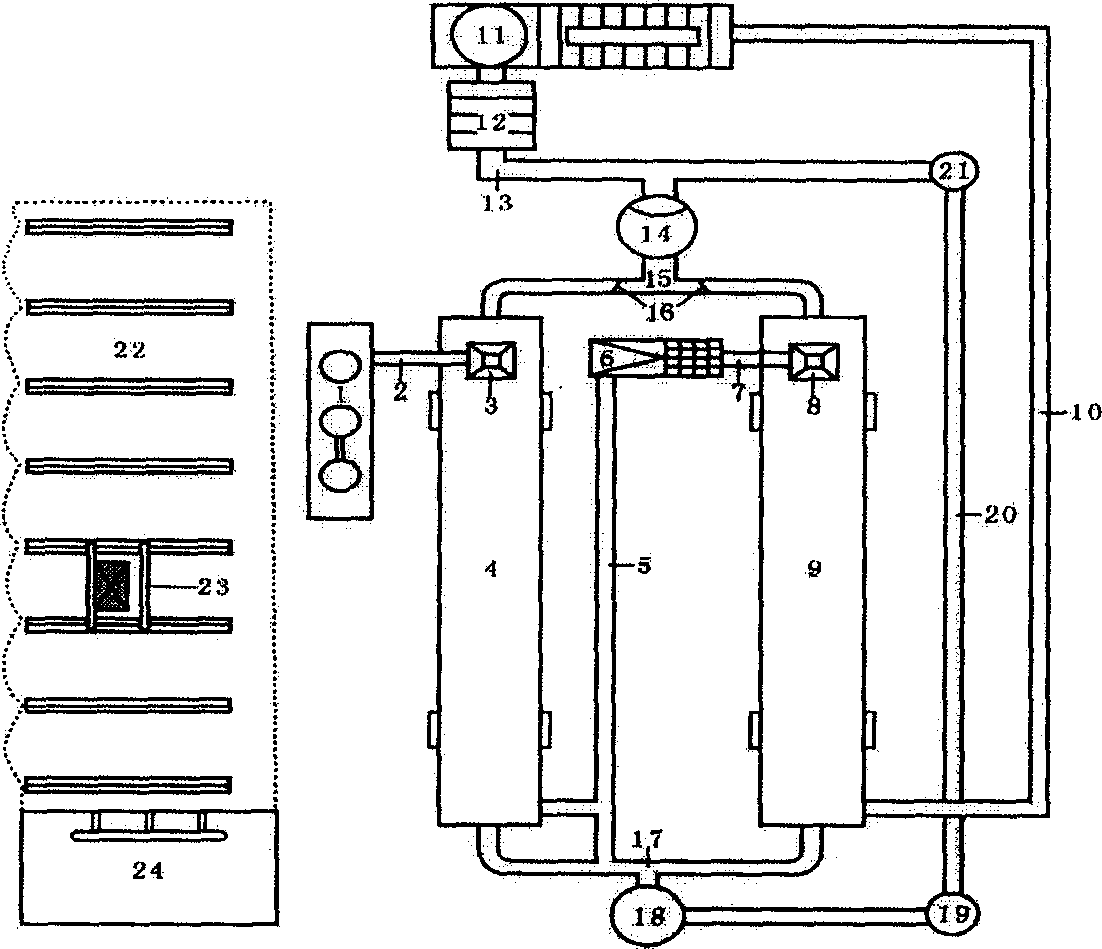

[0019] As shown in the attached figure, the integrated system for drying sludge and sludge power generation by using the waste heat of flue gas in waste-to-energy plants includes a sludge pretreatment system, a feed system, a heat source system, a sludge drying system, a dedusting and degassing system, and a waste Sludge incineration power generation system; the sludge pretreatment system has a trough-type sludge dump (22), and a mixer 23 and a soil biological filter bed 24 are arranged in the trough-type sludge dump; the feeding system has extruded strips connected in sequence machine 1, the first bucket elevator 2 and the first feed port 3; the heating system has a garbage sludge incineration power generation device 11, a composite dust removal device 12, a flue 13, a first induced draft fan 14, The first ventilation pipe 15, the damper 16, and the damper 16 are respectively connected with the first rotary drying kiln 4 and the second rotary drying kiln 9; the sludge drying s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com