Deep deacidification and white smoke removing system and method for flue gas of garbage power plant

A technology for power plants and flue gas, applied in the field of flue gas deacidification and dewhitening systems, can solve the problems of high power, difficult to achieve, and high energy consumption of the absorption liquid circulating pump, and achieves the solution of atmospheric haze pollution and reduction of moisture content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

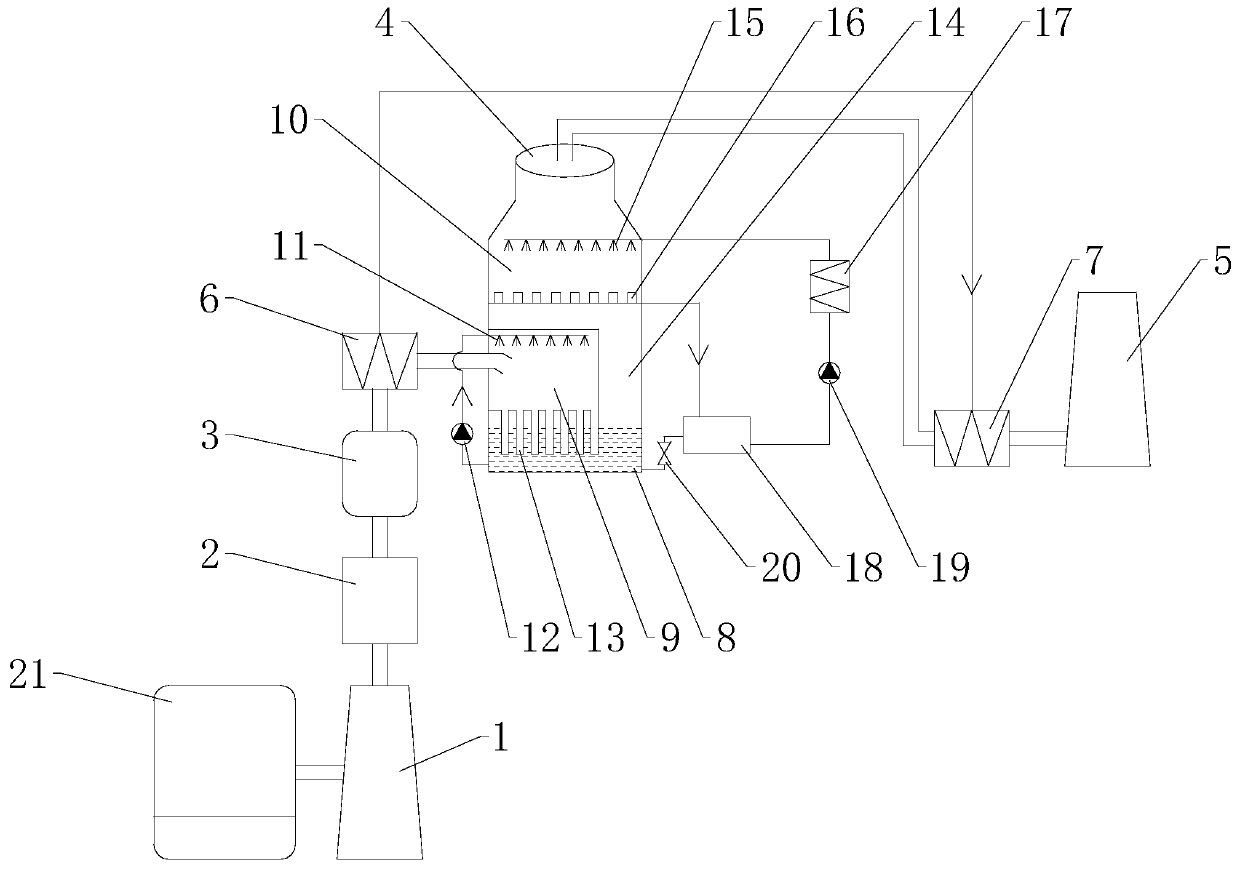

[0030] refer to figure 1 , The deep deacidification and whitening system of flue gas in a garbage power plant of the present invention includes a desuperheating tower 1, an activated carbon injector 2, a bag filter 3, a wet tower 4, and a chimney 5.

[0031] The flue gas inlet of the desuperheating tower 1 is connected to the exhaust port of the garbage incinerator 21, the flue gas outlet of the desuperheating tower 1 is connected to the activated carbon injector 2, and the flue gas outlet of the activated carbon injector 2 is connected to the bag filter 3 , the air outlet of the bag filter 3 is connected to the first heat exchanger 6, and the air outlet of the first heat exchanger 6 is connected to the wet tower 4, and the rear stage of the wet tower 4 is connected to the second heat exchanger 7, The air outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com