Construction method for integrally and downward putting cofferdam ring beams by means of continuous jack method

A construction method and jacking technology, applied in infrastructure engineering, construction, etc., can solve problems such as high construction safety risks, large labor force, and difficulty in synchronous control, so as to reduce the amount of high-altitude operations, avoid labor force, and reduce the assembly of ring beams the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

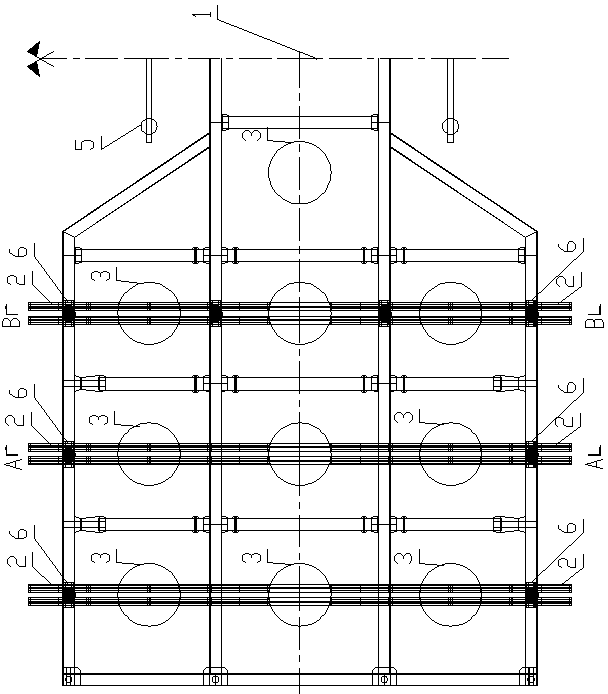

[0031] figure 1 Number 1 shows the axis of the bridge. Figure 7 The middle mark B shows the position where the steel strands of the upper ring beam are inserted; Figure 9 Center C shows the position where the steel strands of the ring girder of the lower layer are inserted.

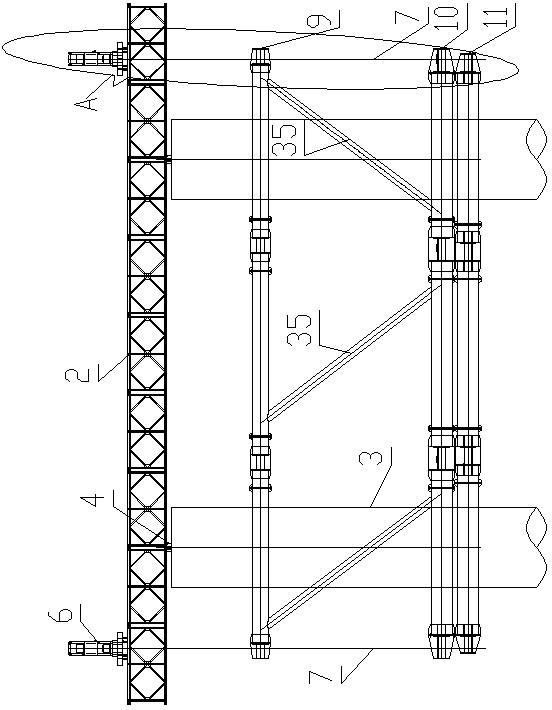

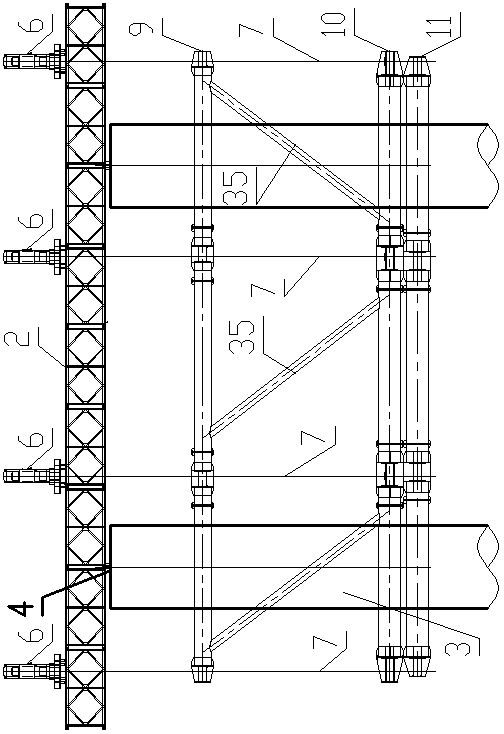

[0032] Such as figure 2 As shown, a steel pipe connection system 35 is provided between the middle ring beam 10 and the upper ring beam 9 .

[0033] Such as Figure 1 to Figure 9 As shown, the continuous jack method cofferdam ring beam integral lowering construction method of the present invention is carried out according to the following steps successively:

[0034] The first step is to install the ring beam suspension system. This step includes the following sub-steps:

[0035] ① Install the ring beam and lower the Bailey beam 2, such as Figure 1 to Figure 3 As shown, there are more than 6 groups of Bailey beams 2 on the top floor, preferably 6 groups, and the laying of the Bailey beams 2 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com