Curing formation equipment of positive temperature coefficient (PTC) heating device

A heating device, curing molding technology, applied in the direction of ohmic resistance heating parts, electric heating devices, electrical components, etc., can solve problems such as loose aluminum tube heating elements, large power consumption, and non-parallel sides of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

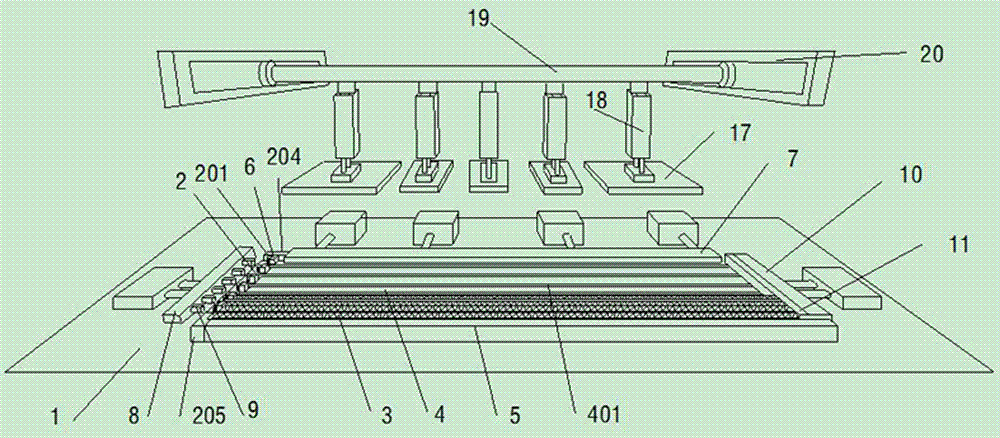

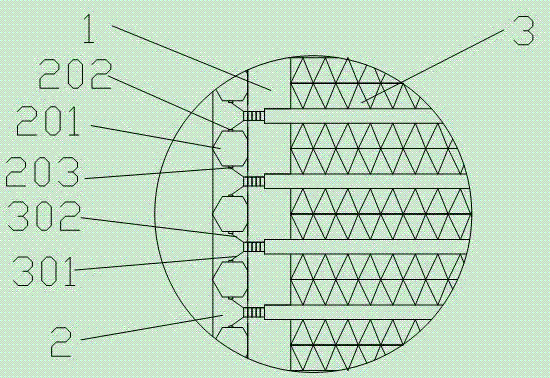

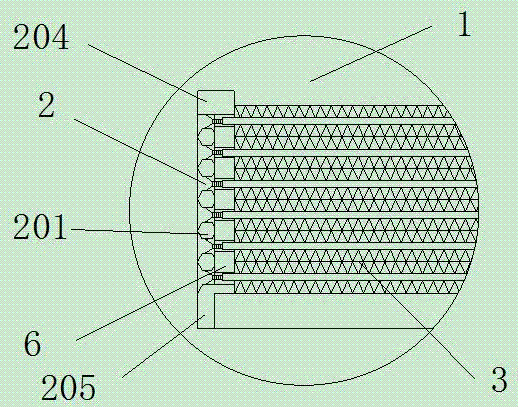

Embodiment 1

[0049] Such as Figure 1~3 The solidification molding equipment of a kind of PTC heating element shown, comprises console 1, and described console one end is fixed with circuit board 2, and described circuit board 2 is provided with several No. 1 fixing blocks 201 alternately, and No. 1 fixing blocks 201 The two sides are respectively provided with a positive electrode head 202 and a negative electrode head 203, and the PTC heating element 3 is arranged on the console 1, and the positive electrode sheet 301 and the negative electrode sheet 302 of the electrode lead-out end of the PTC heating element 3 are connected to the positive electrode head 202 and the negative electrode head respectively. 203 connection, there is a groove 4 corresponding to the PTC heating device 3 on the operating table 1, and the width of the groove 4 is greater than or equal to the width of the heating element of the heating device.

[0050] Further, the groove 4 has a convex strip 401 in the middle. ...

Embodiment 2

[0060] Such as figure 1The non-leading tail end surface positioning device of the solidification molding equipment of a PTC heating device as shown includes an operation table 1, a circuit board 2 is fixed at one end of the operation table, and a PTC heating device 3 is arranged on the operation table 1, and the PTC heating device 3 A current loop is formed with the circuit board 2, and the positioning device includes a No. 3 push plate 10, which pushes and positions the end of the PTC heating element 3 in the width direction through the No. 3 push plate 10. The positioning device is arranged at one end of the console 1 .

[0061] Further, between the No. 3 push plate 10 and the end of the PTC heating element 3, there is an adjustment spacer 11 parallel to the No. 3 push plate 10 and the end of the PTC heating element 3. The adjustment spacer 11 is controlled and promoted by No. 3 push pedal 10 .

Embodiment 3

[0063] Such as Figure 8 The electrode lead-out positioning device of the solidification molding equipment of a PTC heating device as shown includes an operation table 1, a circuit board 2 is fixed at one end of the operation table, and a PTC heating device 3 is arranged on the operation table 1, and the PTC heating device 3 and The circuit board 2 forms a current loop, and the electrode lead-out positioning device includes a positioning baffle 12, the positioning baffle 12 is perpendicular to the console 1, and the positioning baffle 12 is connected to the PTC heating element 3 placed on the console 1 The lead-out end faces of the electrodes are parallel and close to each other, and there is a No. 2 groove 13 for accommodating and leading out the lead-out electrodes at the position corresponding to the lead-out electrodes of the heating element 3 at the wall thickness of the positioning baffle 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com