Aromatic polyamide composite membrane

An aromatic polyamide and composite diaphragm technology, applied in electrical components, electrochemical generators, circuits, etc., can solve problems such as affecting the production process, large fiber gaps, affecting production efficiency, etc., to simplify the production process and the preparation process. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

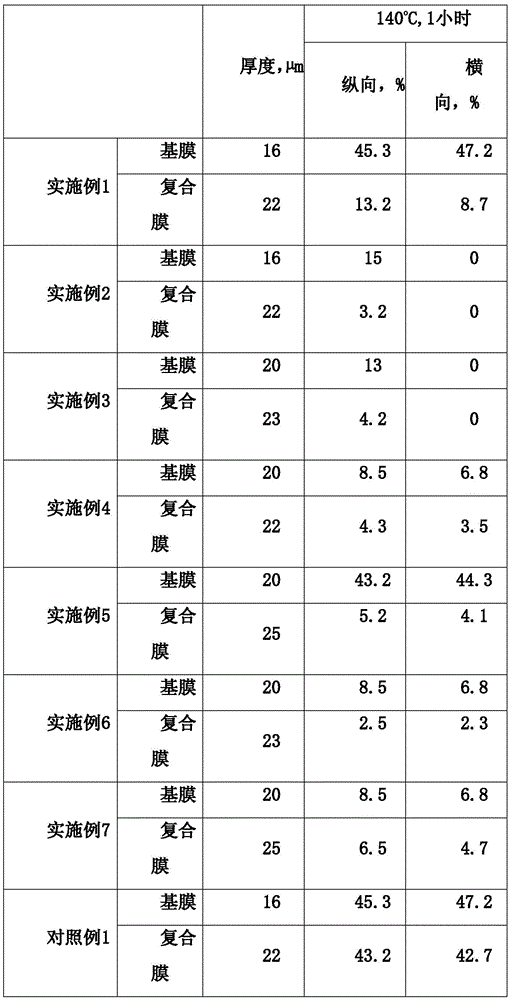

[0041] Now introduce an example of the preparation method of the present invention. In an embodiment of the method for preparing the composite diaphragm of the present invention, the method includes the following steps: add lithium salt to solvent A to dissolve completely, and then add aromatic polyamide and stir until completely dissolved , Slowly add an appropriate amount of water while stirring, control the water content so that the aromatic polymer does not precipitate directly from the solvent to obtain component A 1 . After adding inorganic nanoparticles and high-temperature closed-cell material in solvent B to fully disperse, add gel polymer to stir and dissolve and then disperse evenly to obtain component B 1 . Component A 1 Can be used alone as a coating liquid, or combined with component B 1 It is used as a coating liquid after being uniformly mixed and dispersed. The coating liquid is coated on one or both surfaces of the porous base film and dried to obtain the arom...

Embodiment 1

[0051] Add 10 parts of LiTFSI to 100 parts of DMAC and stir until it is completely dissolved, then add 10 parts of Aramid 1313 and continue to stir until completely dissolved, and then slowly drop 10 parts of deionized water into the solution to obtain component A 1 As a coating liquid. A 16μm thick polyethylene monolayer membrane prepared by wet biaxial stretching and a porosity of 40% was immersed in the resulting coating solution to obtain an aromatic polyamide composite with a 3μm thick coating on both sides after drying. Diaphragm. The performance of the composite diaphragm is shown in Table 1.

Embodiment 2

[0053] Add 10 parts of LiTFSM to 80 parts of NMP and stir until it is completely dissolved, add 10 parts of Aramid 1313 and continue to stir until completely dissolved, and then slowly drop 10 parts of deionized water into the solution to obtain component A 1 . Add 5 parts of PEO to 80 parts of DMAC, and obtain component B after complete dissolution 1 . Component A 1 And component B 1 After mixing uniformly, a coating liquid is formed. A polypropylene monolayer membrane with a thickness of 16μm and a porosity of 50% prepared by dry single drawing was immersed in the resulting coating solution to obtain an aromatic polyamide composite membrane coated with a 3μm thick coating on both sides after drying. . The performance of the composite diaphragm is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com