Prefabricated cast-in-place combination type superposed shear wall

A technology of superimposed shear walls and shear walls, applied to walls, building components, buildings, etc., can solve the problems of unsatisfactory industrialized residential walls and housing shortages, and achieve the improvement of drawing strength, reduction of high-altitude operations, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

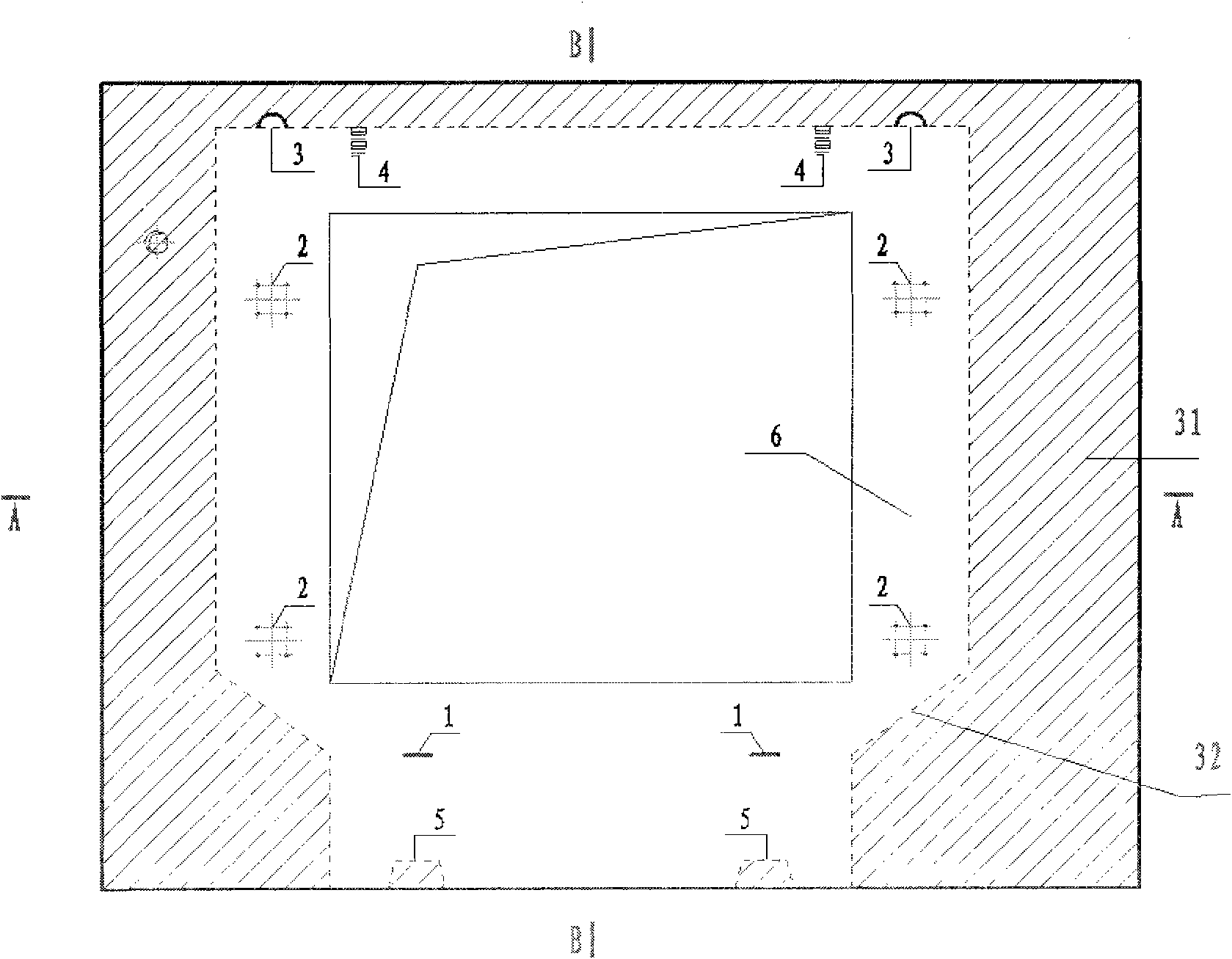

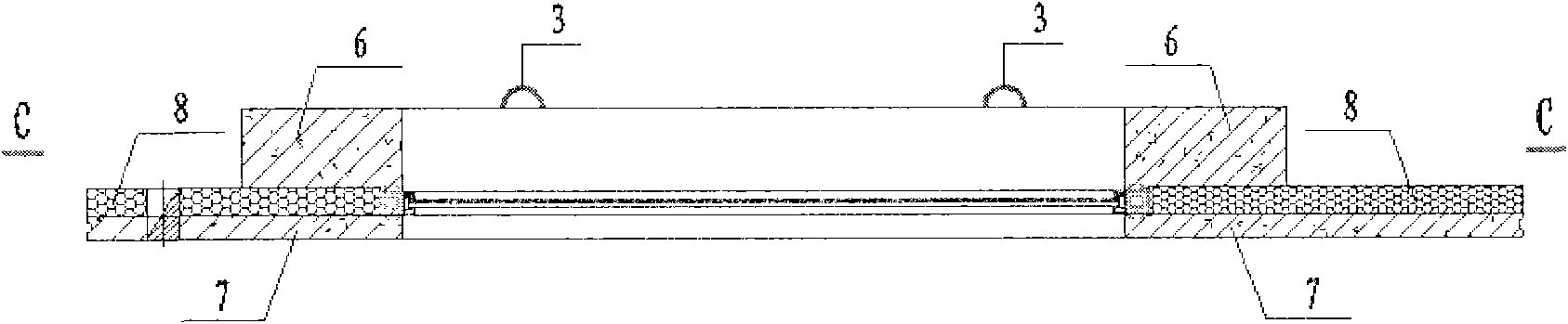

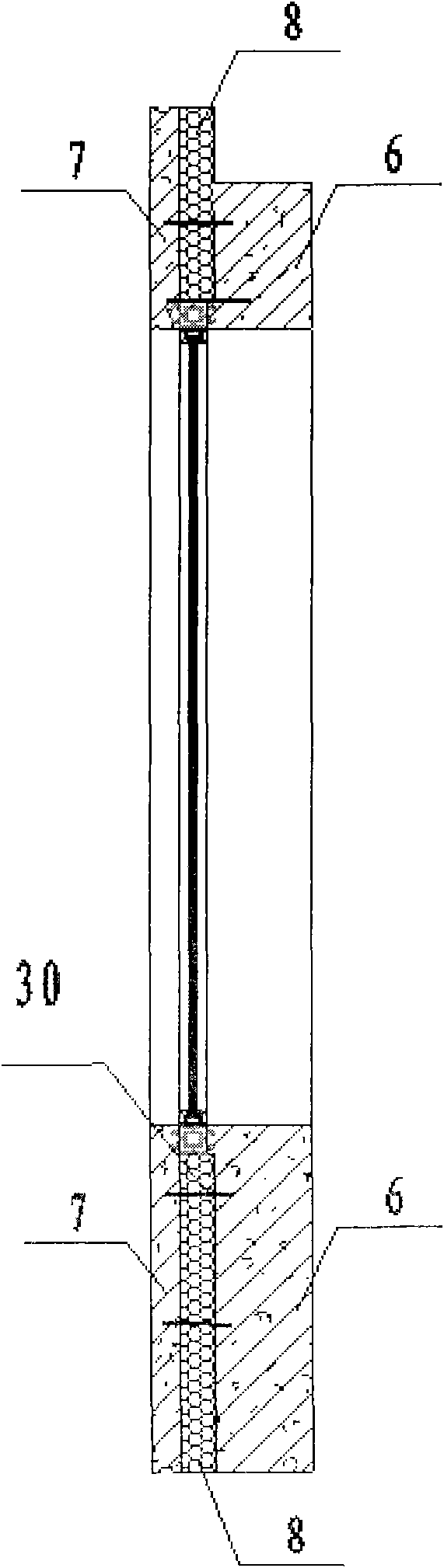

[0044] Such as Figure 1 to Figure 6 Shown is a shear wall structure with a window, including an outer wall 7, an insulating material layer 8, and an inner wall 6, and the insulating material layer 8 is interposed between the outer wall 7 and the inner wall 6 Between, the inner leaf wall 6 and the outer leaf wall 7 are connected by a connector 30, the inner leaf wall 6 is composed of two parts, one part is a prefabricated part, and the other part is a cast-in-place part 31, and the inner leaf wall 6 The prefabricated part is located in the middle part of the outer leaf wall 7, and the area of the prefabricated part of the inner leaf wall 6 is smaller than the outer leaf wall 7 to reserve the space of the cast-in-place part, the inner leaf wall 6 and the outer leaf wall 7 and The insulation material layer 8 reserves the position of the window, and the window frame is made into one with the prefabricated part; as Figure 4 ~ Figure 6 As shown, the prefabricated part of the in...

Embodiment 2

[0052] Figure 7 ~ Figure 10It is another kind of embodiment of the present invention, and the difference between this embodiment and embodiment 1 is: the shear wall does not have reserved hole (window), but integral, same as embodiment 1, comprises outer leaf wall 7, insulation Material layer 8, inner page wall 6, the thermal insulation material layer 8 is interposed between the outer page wall 7 and the inner page wall 6, the inner page wall 6 and the outer page wall 7 are connected by tie bars 30, the The inner wall 6 is made up of two parts, one is a prefabricated part, and the other is a cast-in-place part 31. The prefabricated part of the inner wall is located in the middle of the outer wall 7, and the area of the prefabricated part of the inner wall is smaller than the The outer page wall 7 is to reserve the space of the cast-in-place part, and the inner page wall is also provided with a lifting point 3, a steel bar handle 1, and a position adjustment device; the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com