U-shaped movable hold hoop type lifting lug for hoisting tower facility and hoisting method thereof

A U-shaped, lifting lug technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of large consumption and increase of steel, and achieve the effect of low production cost, convenient use and speeding up the progress of the project.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

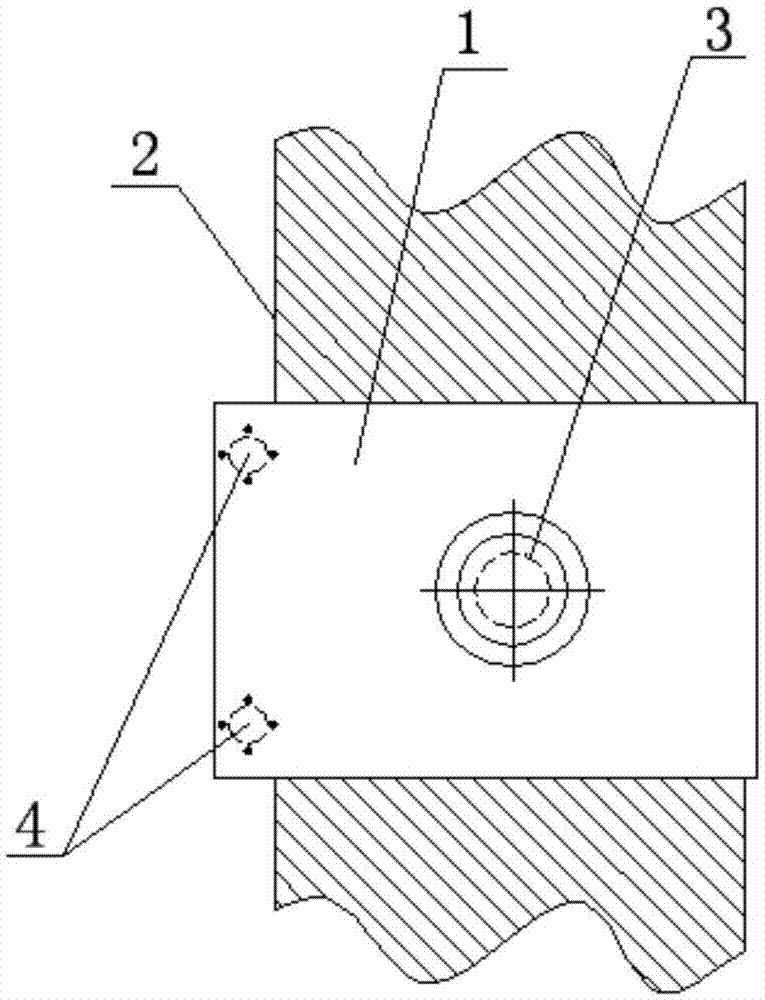

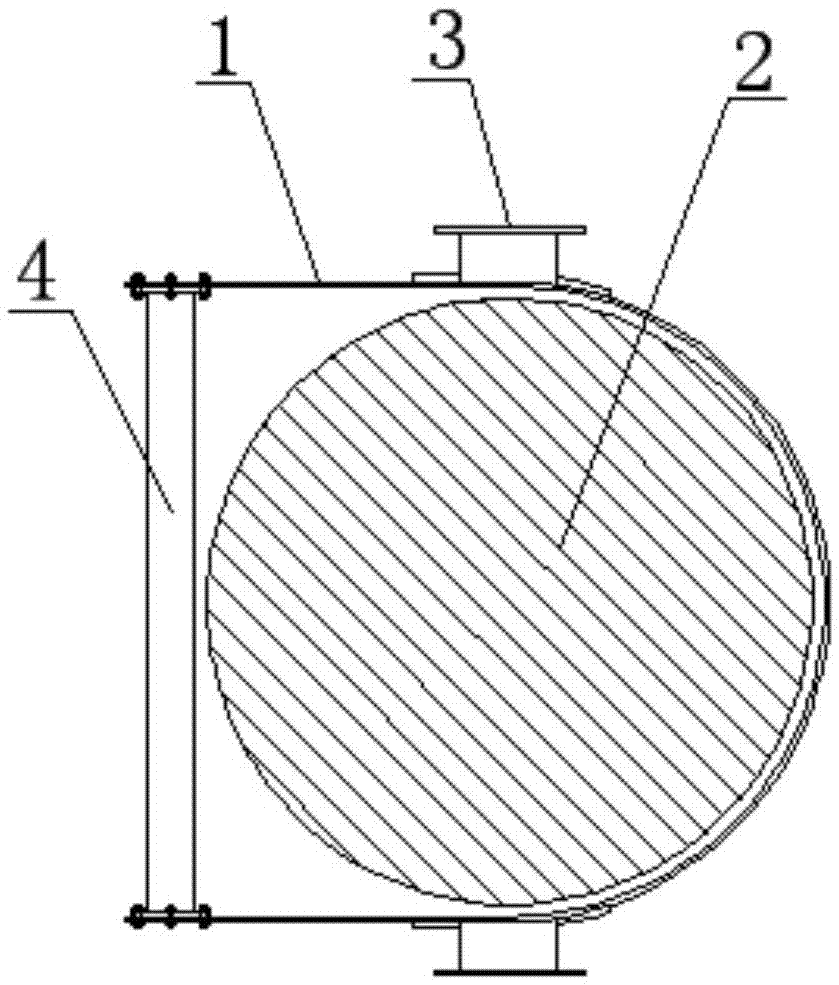

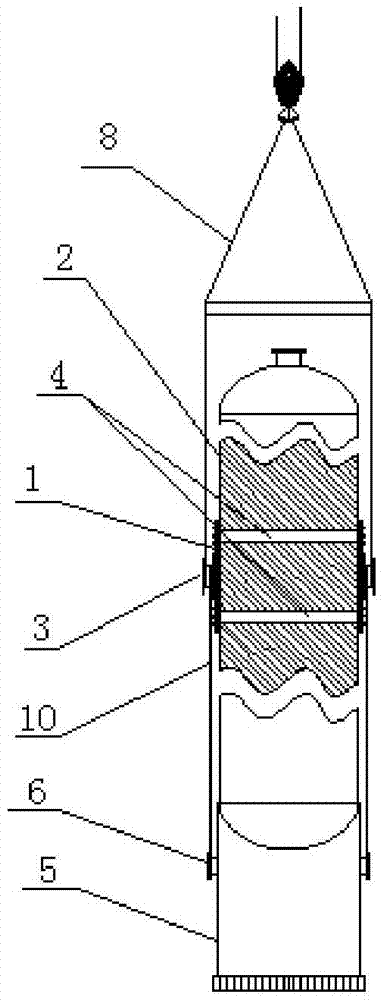

[0029] like figure 1 , 2 As shown, a U-shaped movable hoop-type lifting lug for tower equipment hoisting according to the present invention includes a U-shaped hoop 1, which is formed by bending a steel plate, and the thickness of the bent plate of the U-shaped hoop 1 is 30mm, the hoop of U-shaped hoop 1 is hooped on the side wall of tower body 2. The diameter of the tower is 2.5m, the height is 54m, and the weight is 98t. The curvature of the hoop of U-shaped hoop 1 is the same as that of the side wall of tower body 2. The curvature of the U-shaped hoop 1 is symmetrical, and a pair of tube-shaft lifting lugs 3 are symmetrically arranged on both sides of the U-shaped hoop 1. The tube-shaft lifting lugs 3 are made of steel pipes on site. It just falls on the axis connection of the two tubular lifting lugs 3. There is a reinforcing ring between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com