Device and method for constructing assembled crossing frame

A spanning frame and vertical technology, which is applied in the field of devices for constructing vertical spanning frames, can solve the problems of high labor intensity of construction personnel, inability to ensure verticality, and cumbersome assembly methods, etc. The effect of high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

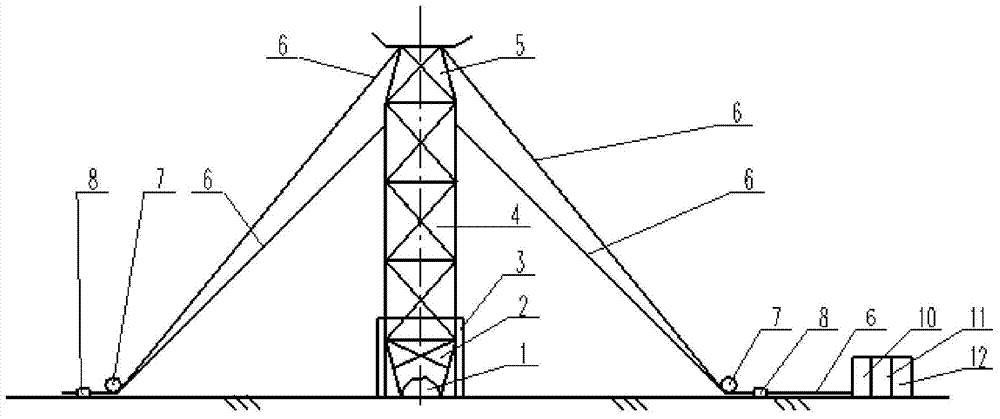

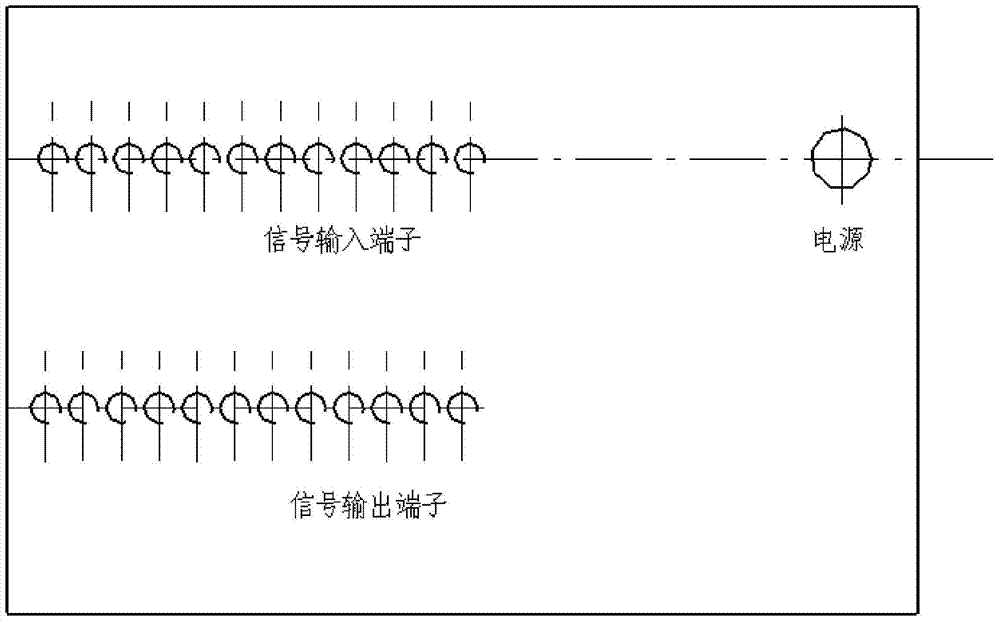

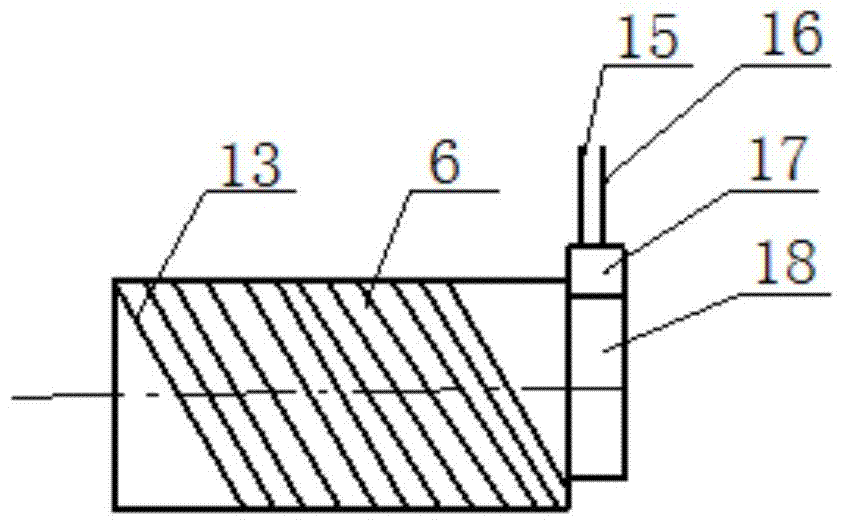

[0039] In this embodiment, the device for constructing a vertical spanning frame is taken as an example, such as figure 1 As shown, the spanning frame provided by the embodiment of the present invention is vertically arranged on the horizontal base 1, including: the tower root 2, the middle section 4 and the tower head 5; the jacking frame 3 is arranged around the tower root 2; and the jacking frame 3 is located A synchronous control device 10, a retractable rope mechanism 11 and a power source 12 are arranged on the same plane; two layers of pull wires 6 are arranged symmetrically on both sides of the tower head 5 and the middle section 4, and a steering wheel is arranged between the pull wire 6 and the retractable rope mechanism 11. The pulley 7 and the tension sensor 8; the jacking frame 3, the synchronous control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com