High-altitude large-span curved roof hydraulic lifting construction method

A technology of hydraulic lifting and hydraulic lifter, applied in the field of structural engineering steel structures, can solve the problems of uneconomical hoisting of large-scale equipment, long cycle, and difficulty in assembling space components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

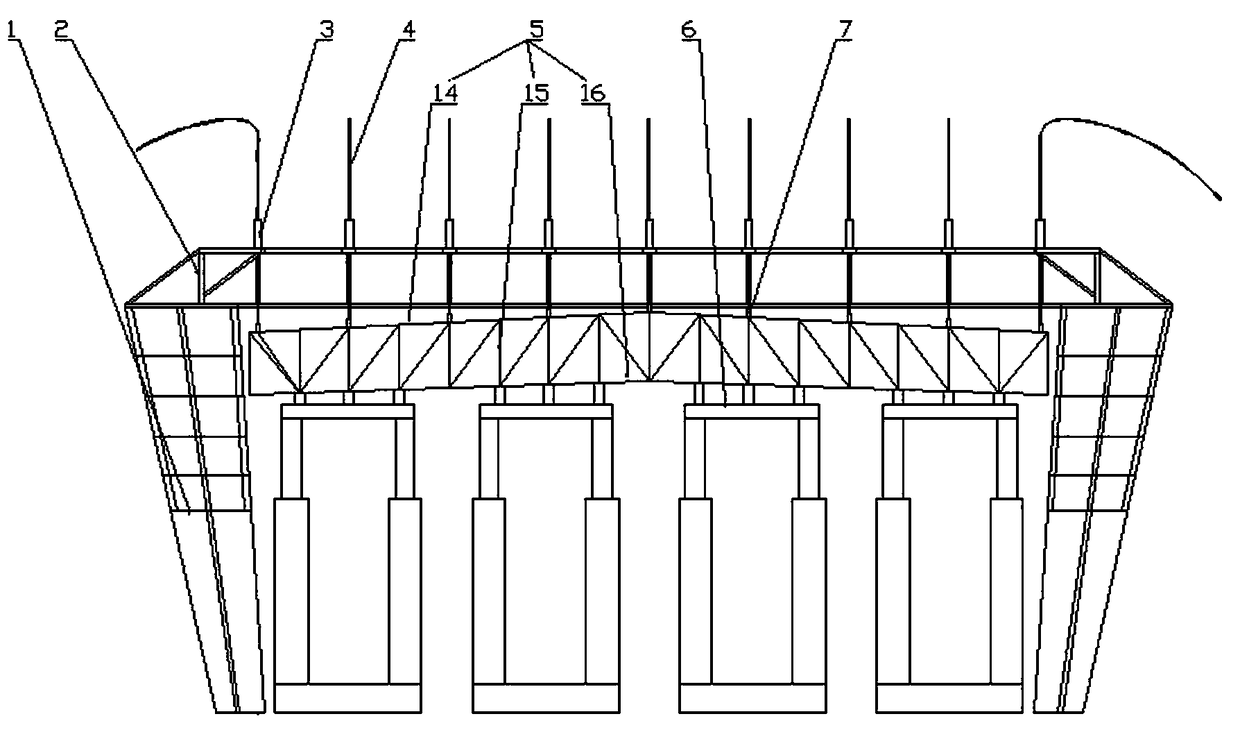

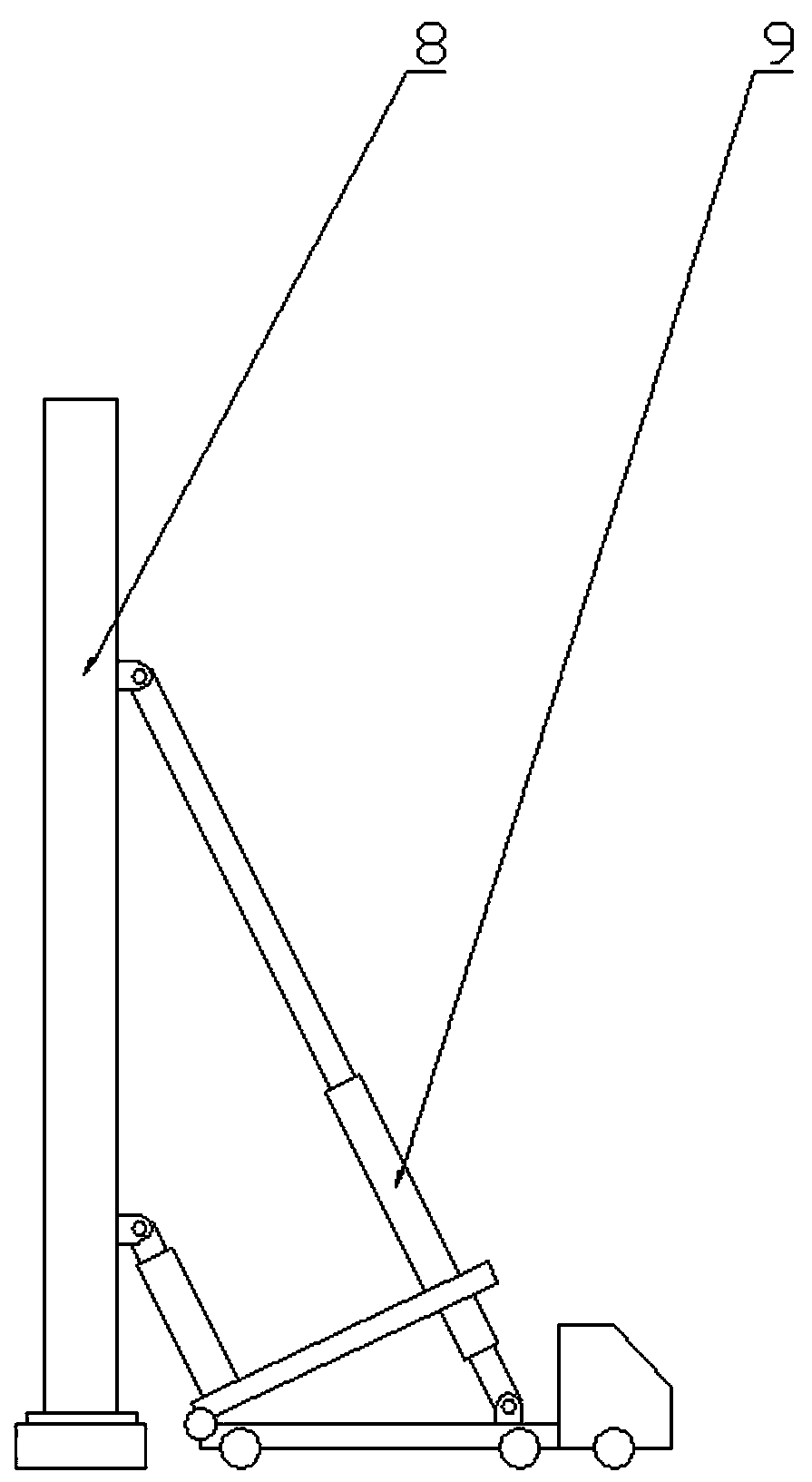

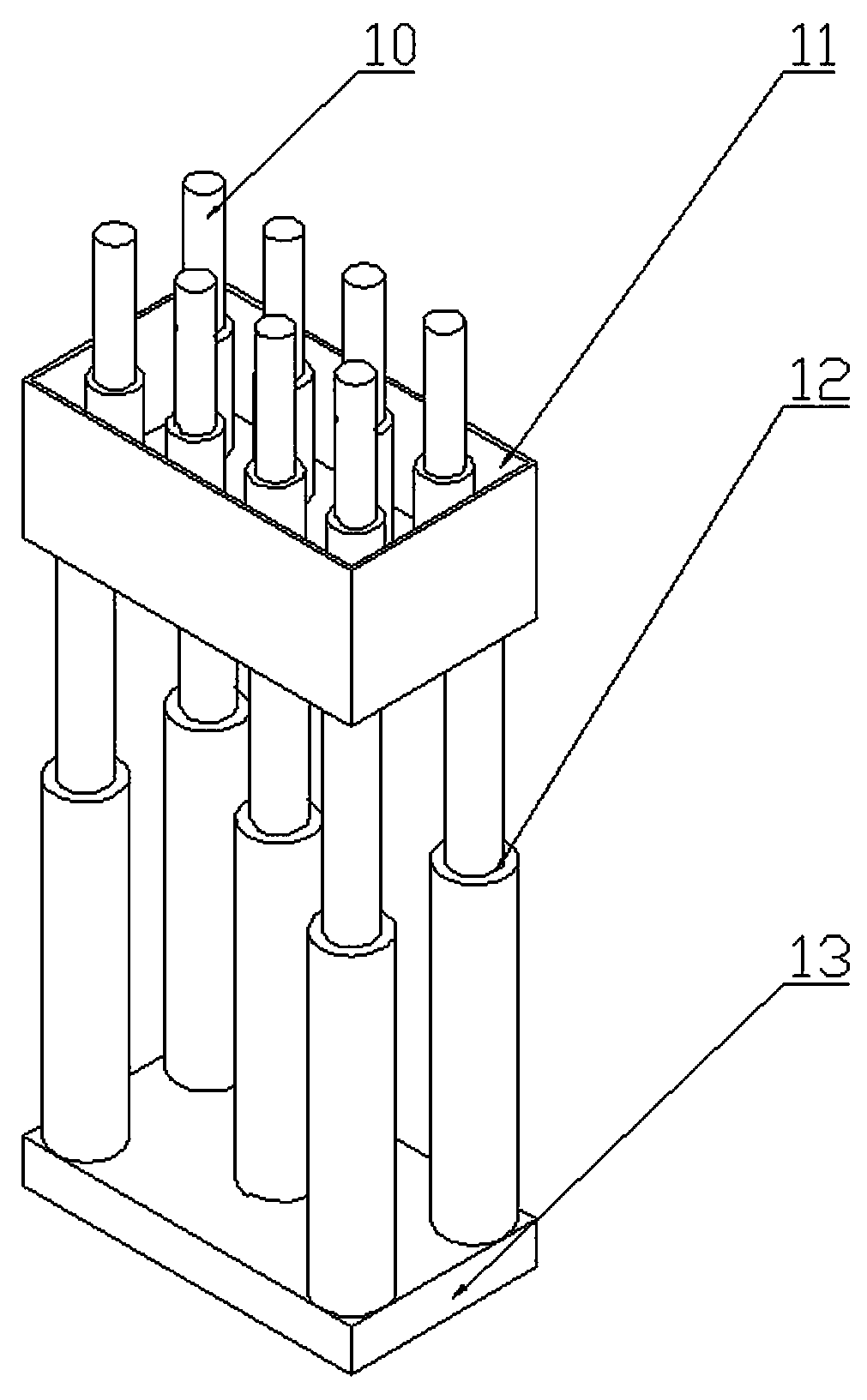

[0027] Example: such as figure 1 , figure 2 with image 3 As shown, a high-altitude large-span curved roof hydraulic lifting device includes a curved roof 5. The curved roof 5 includes a truss upper chord 15. The upper end of the truss upper chord 15 is provided with a roof surface 14 that is filled and welded with the truss upper chord 15. The truss The bottom of the upper chord 15 is provided with the lower chord 16 of the truss which is embedded and welded with the upper chord 15 of the truss, the lower end of the lower chord 16 of the truss is provided with a number of roof support columns 8, and the side of the roof support column 8 is equipped with a hydraulic column car with lug-type screw connection 9. Several roof support columns 8 are provided with a number of hydraulic lifting assemblies 6 that are lifted and fixed with the lower end surface of the lower chord 16 of the truss. The upper end surface of the hydraulic support cylinder 12 is provided with a guardrai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com