Multifunctional flue gas treatment system

A flue gas treatment system and multi-functional technology, which can be used in gaseous discharge wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Single function and other problems, to achieve the effect of full utilization, simple structure and reducing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

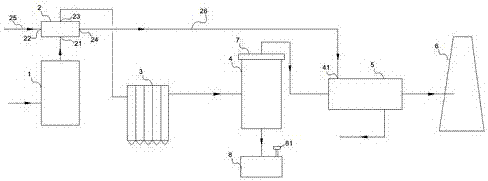

[0024] This embodiment provides a multifunctional flue gas treatment system, which can not only effectively remove sulfur dioxide and nitrogen oxides in the flue gas, but also effectively utilize waste heat and treat waste water. For details, please refer to figure 1 The schematic diagram of the structure is shown.

[0025] The multifunctional flue gas treatment system includes an SCR denitrification unit 1 , a flue gas-air heat exchange unit 2 , a bag-type dust removal unit 3 , a desulfurization tower 4 , a heating unit 5 and a smoke exhaust unit 6 connected in sequence through pipelines.

[0026] The SCR denitrification unit 1 is used to remove nitrogen oxides in the flue gas, the flue gas-air heat exchange unit 2 is used to exchange heat between flue gas and air, and the bag-type dust removal unit 3 is used to remove nitrogen oxides in the flue gas. dust, the desulfurization tower 4 is used to remove sulfur dioxide in the flue gas, and the smoke exhaust unit 6 is used to di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com