Crack width checking and control method of underground continuous wall

A technology of underground diaphragm wall and crack width, applied in the direction of calculation, computer-aided design, special data processing application, etc., can solve the problems of waste of reinforcement reinforcement of ground walls and large results, so as to reduce waste, improve work efficiency and reduce engineering costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

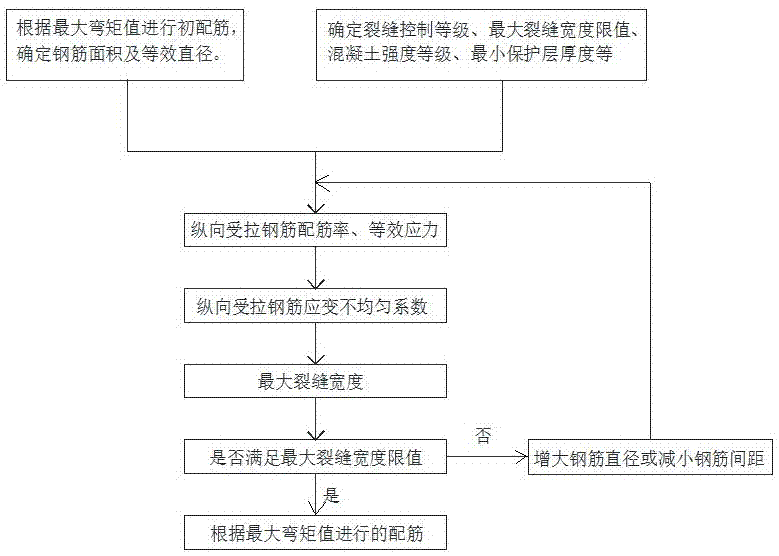

Method used

Image

Examples

Embodiment 1

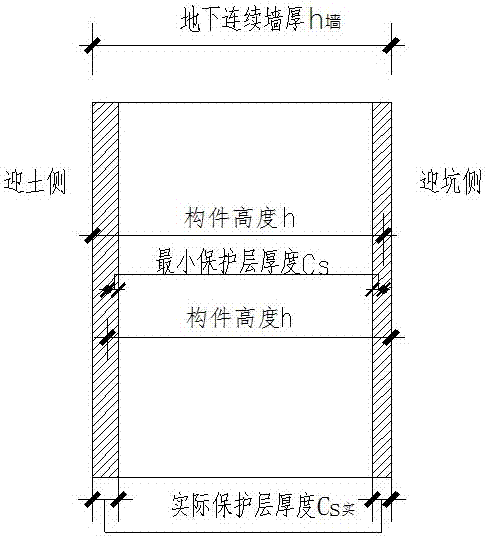

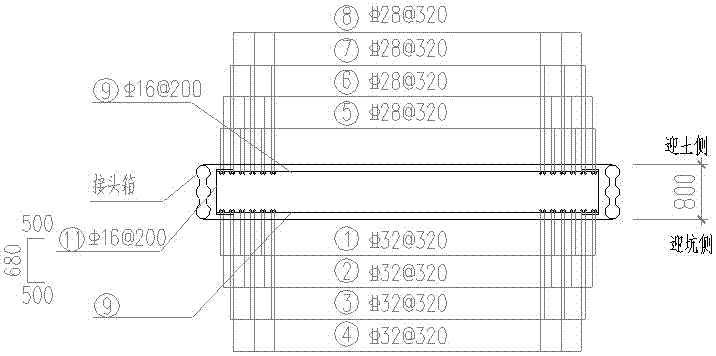

[0044] See attached figure 2 , the excavation depth of the foundation pit project is 14m, and the underground diaphragm wall + three concrete support enclosures are adopted. The combination of the underground diaphragm wall and the main structure is considered as a permanent component. The strength grade of the concrete of the underground diaphragm wall is C35 (ftk=2.20N / mm2), the main reinforcement of the steel bar is HRB400, and the thickness of the diaphragm wall is 800mm (h 墙 ), the thickness of the protective layer on the side facing the soil is 70mm (c s实 ), the thickness of the protective layer on the pit side is 50mm (c s实 ), the ground wall structure is considered as a single-reinforced rectangular cross-section beam, and the component width b = 1000mm. As a part of the permanent structure, the underground diaphragm wall is checked and calculated according to the third-level crack control according to the national standard. The crack width limit on the side facing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com