Method for replacing upper anchor cable of mooring anchor legs

A replacement method and mooring anchor technology, which is applied in the direction of anchoring arrangements, ship components, transportation and packaging, etc., can solve the problems of difficult control of tension, high performance requirements of operating ships, and difficult control of construction progress, so as to achieve dismantling and Easy and efficient installation, satisfying the convenience of construction, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Such as figure 1 — Figure 10 Shown, the present invention adopts following steps:

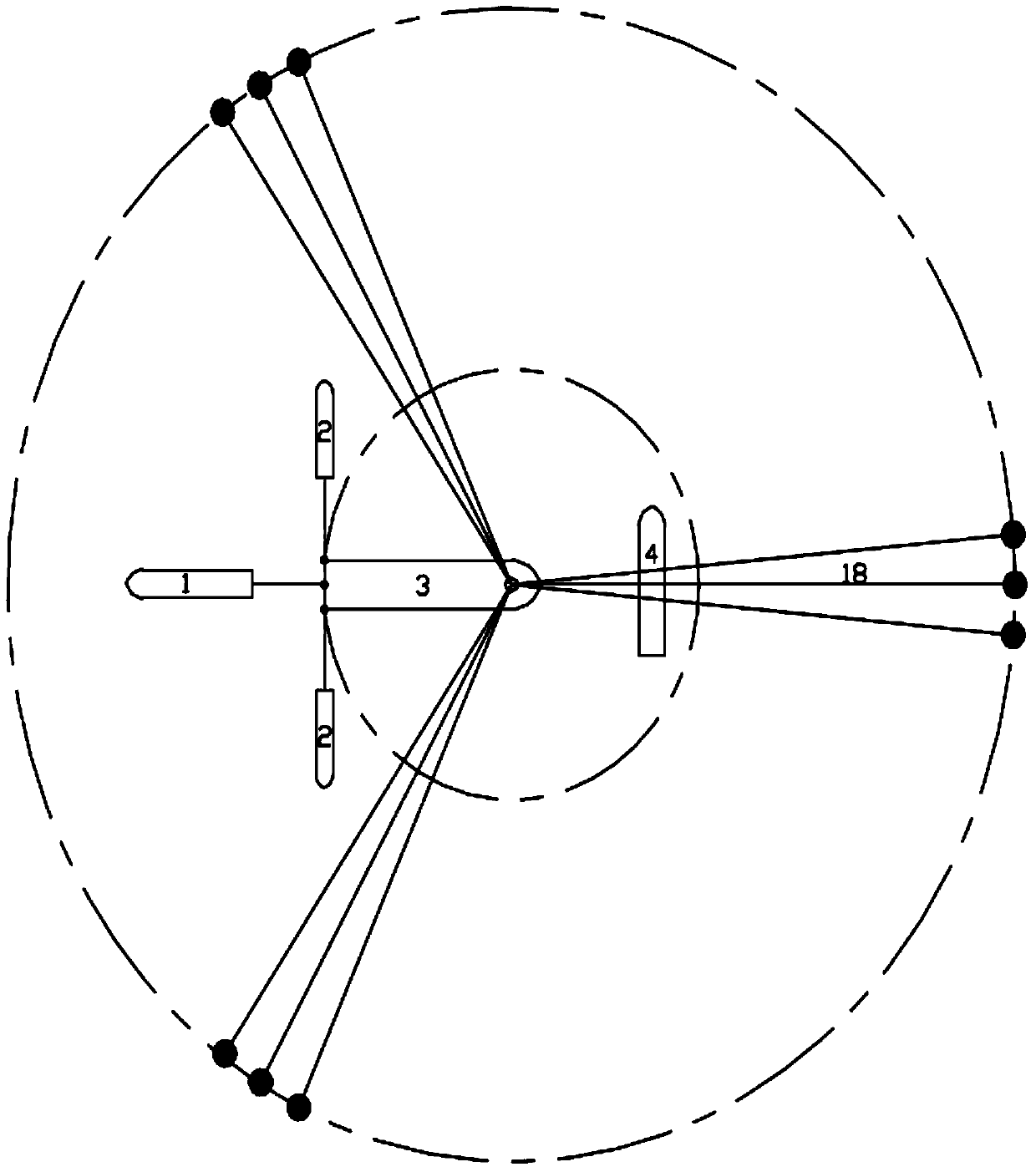

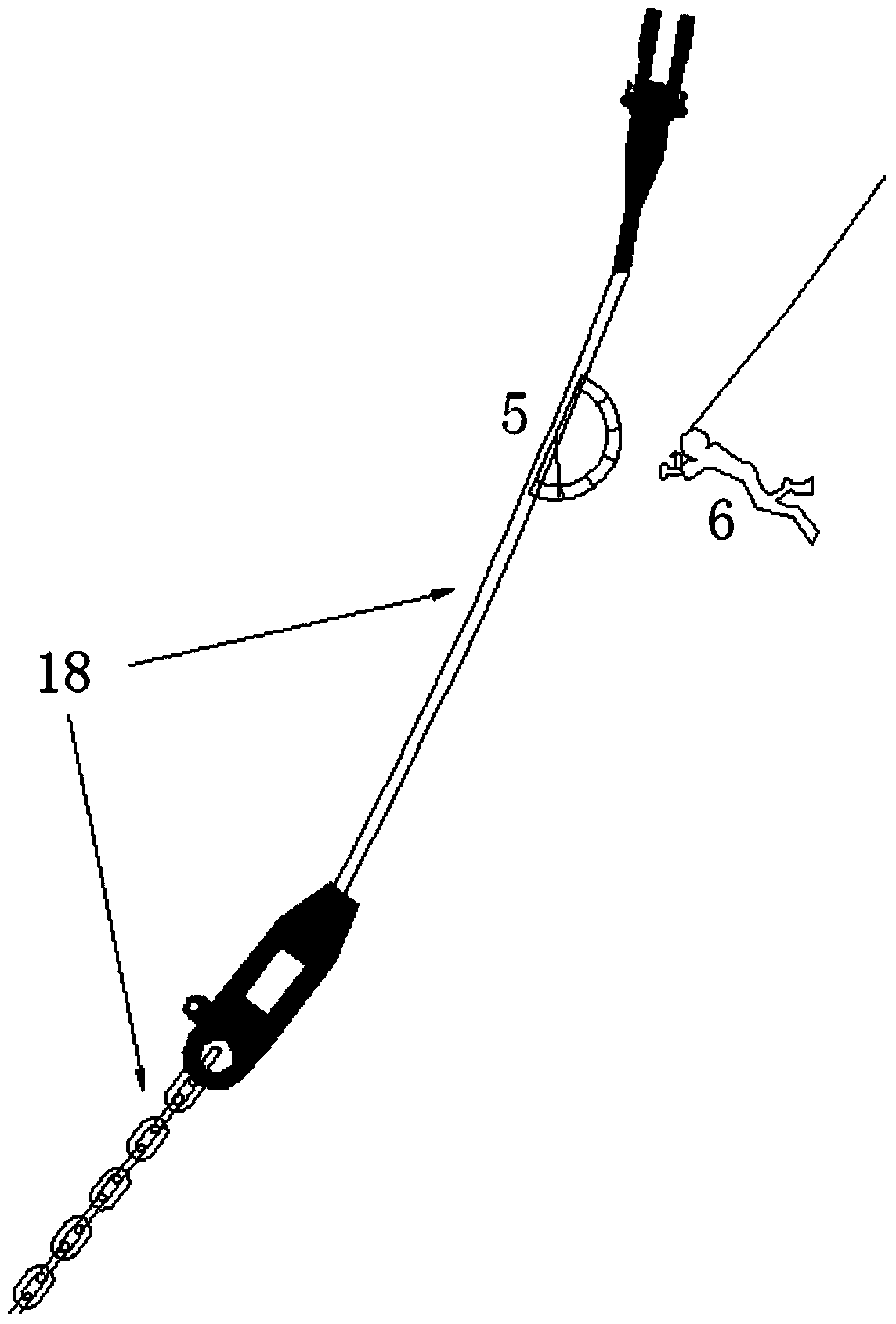

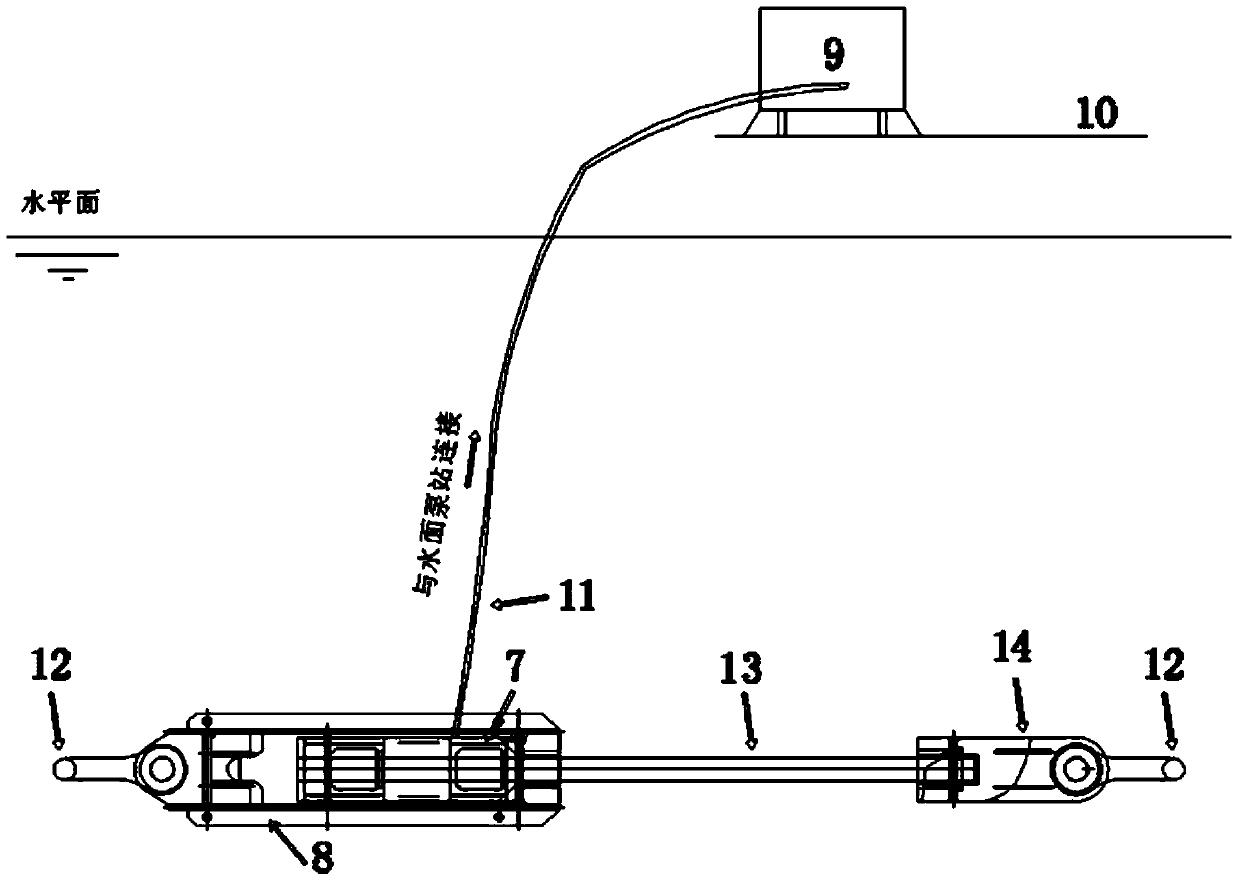

[0050] The first step: if figure 1 As shown, several limit tugboats are arranged at the stern of the FPSO 3, and the tugboats are used to restrict the rotation of the FPSO 3 under the action of wind, waves and currents, so that its heading is at a constant The angle is close; among them, the number and horsepower of the limit tugboat need to be comprehensively determined according to factors such as the size of the floating production storage and offloading tanker 3, the influence of wind and wave current, the influence of internal wave flow, and the maneuverability of the tugboat. Generally, it is determined by a main limit tugboat 1 It is composed of two auxiliary limit tugboats 2; the limit work of the floating production storage and offloading tanker 3 is mainly divided into two types: one is the construction operation of saturation diving, and the other is the disassembly and ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com