Improved method for installing reinforcement cage in beam column joint zone of reinforced concrete frame structure

A technology of reinforced skeleton and column joints, which is applied in the direction of building construction, construction, and building material processing, etc., and can solve problems such as difficult operation, unawareness, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

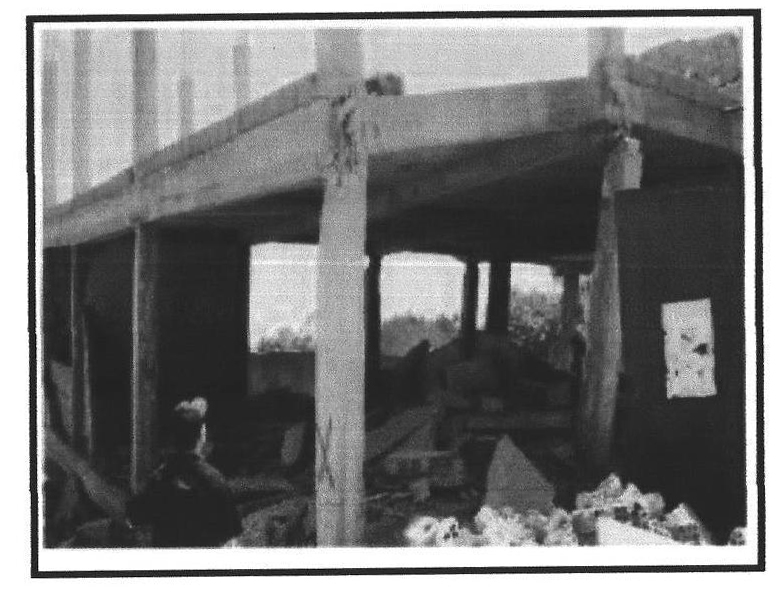

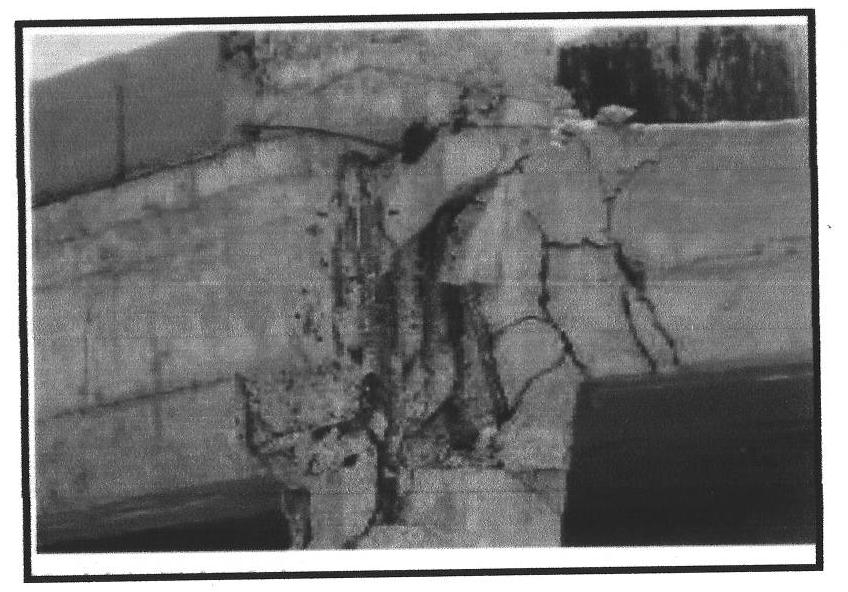

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

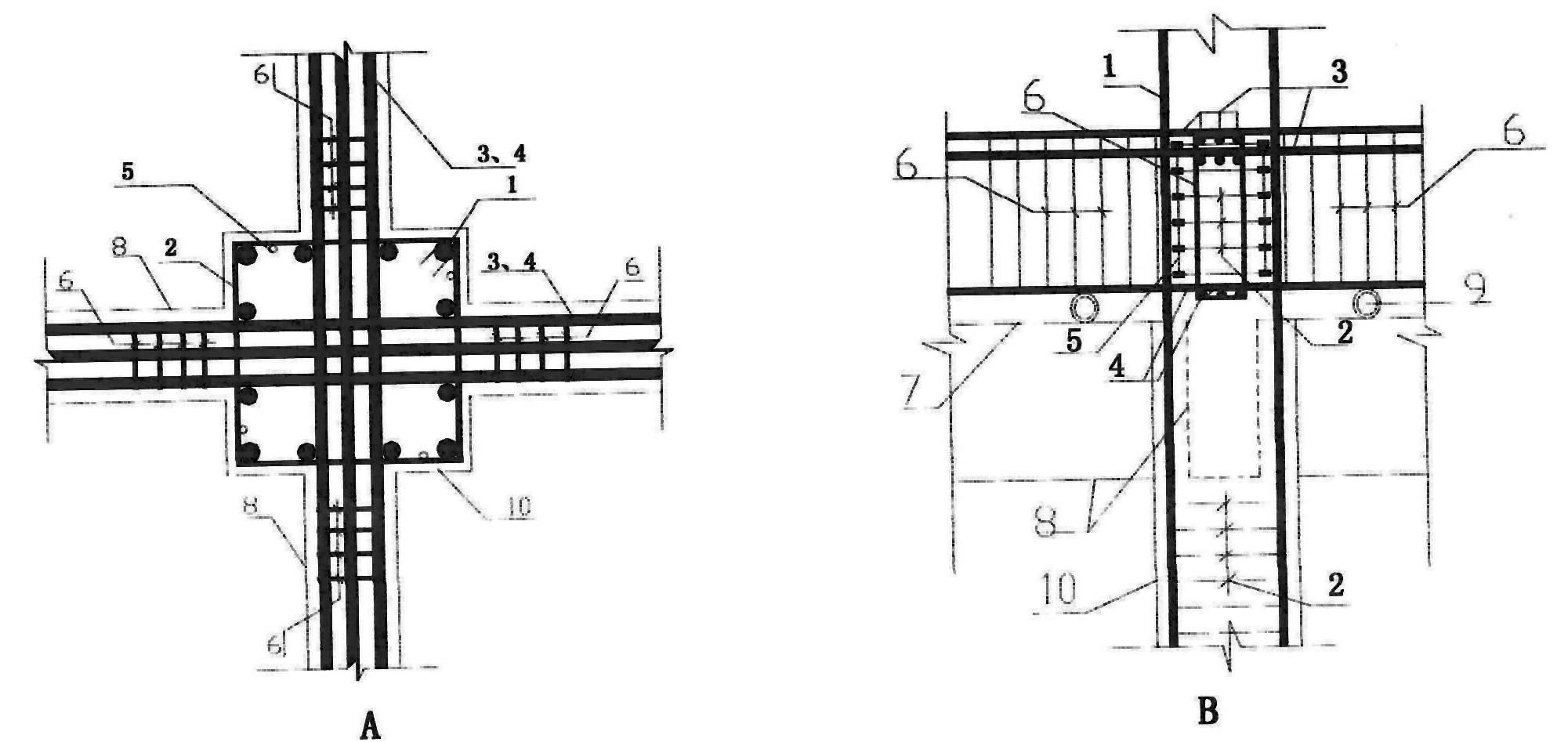

[0013] 1. Make the column stirrup limit mold rod, the structure is as follows Figure 4 Middle B picture. The length of the reinforcing bar head 5 on the limiting mold bar is equal to the height of the larger beam section at the core area of the beam-column joint, the diameter of the short reinforcing bar section 11 is the diameter of the column stirrup, and the length 13 is 2 to 3 cm, and the distance 12 between a pair of short reinforcing bar sections 11 is the column Stirrup diameter, the distance 14 between two pairs is the column stirrup spacing; The manufacturing material of mold bar is the steel bar waste of construction site, can adopt Φ8, Φ10 steel bar to get final product. The specific implementation is as follows: ① Firstly, the mold plate made by prefabricating the limit mold bar with cement mortar (with steel wire mesh inside) is used in the corner of the on-site steel bar processing workshop (details Figure 5 A picture in middle) or a mold that is processed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com