Dual-fuel bulk cargo ship

A dual-fuel, bulk carrier technology, applied in ship construction, ship components, ships, etc., can solve the problems of difficult layout, large volume of LNG fuel tank, complex LNG fuel gas supply system, etc., and achieve the effect of small integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the following examples.

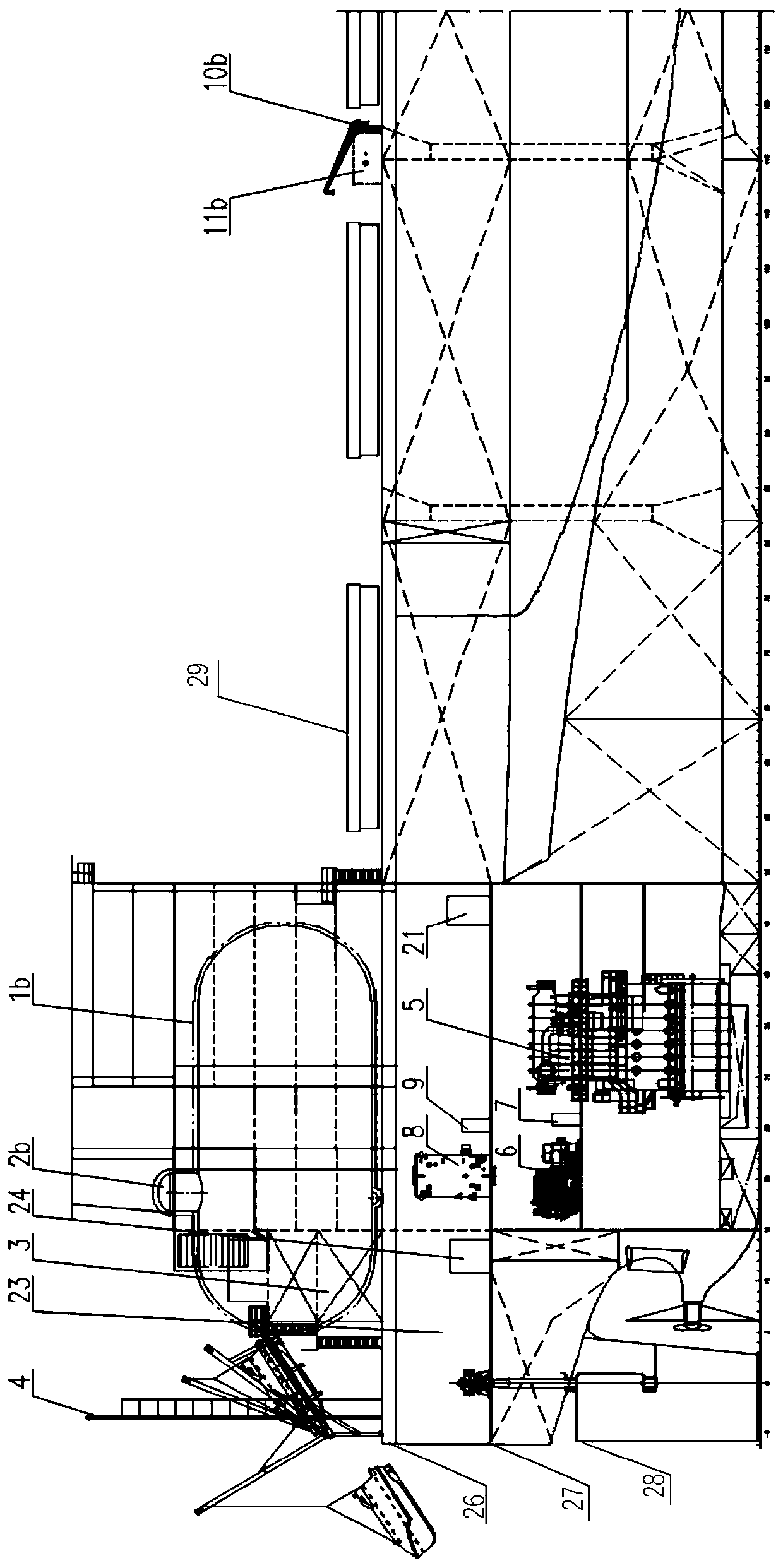

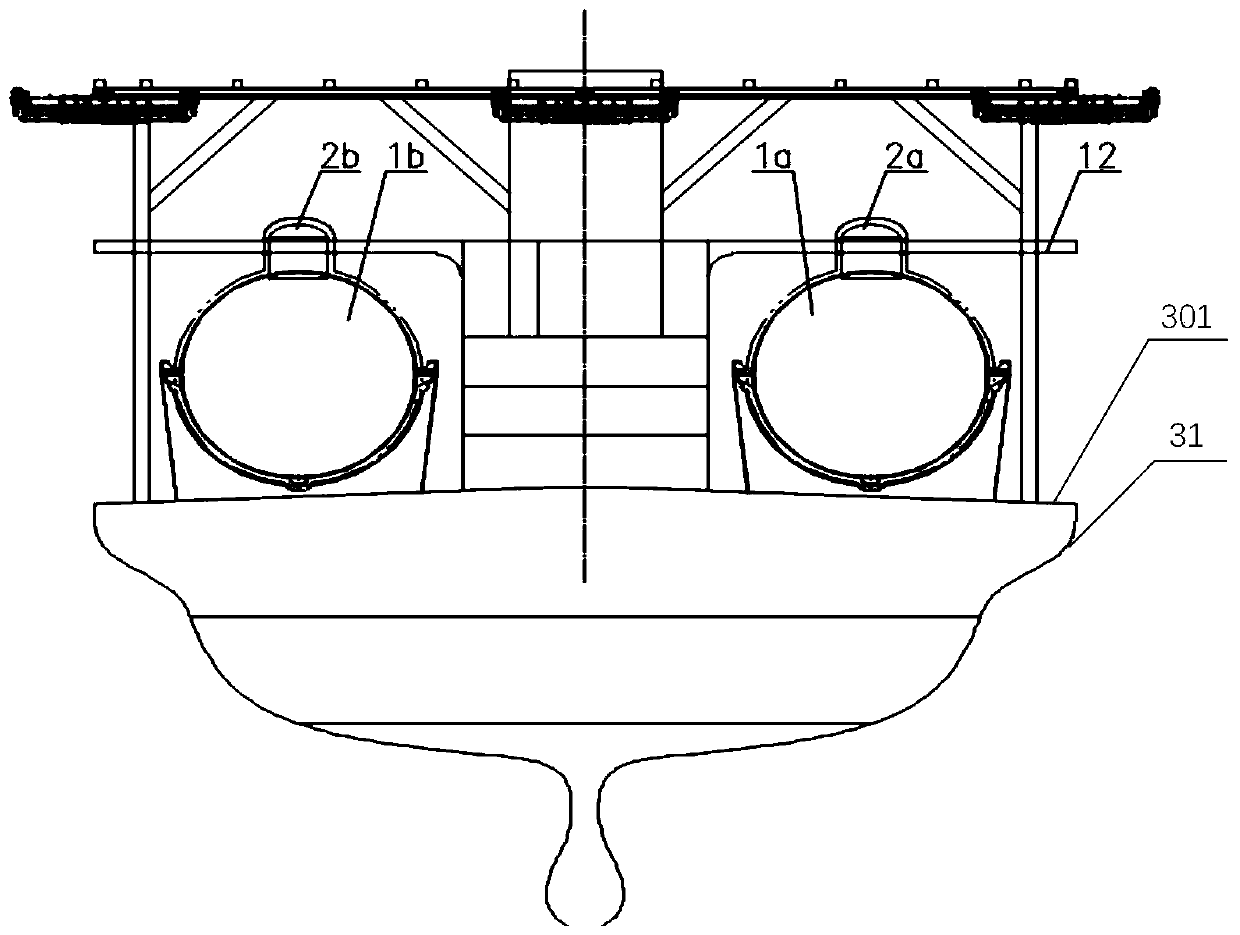

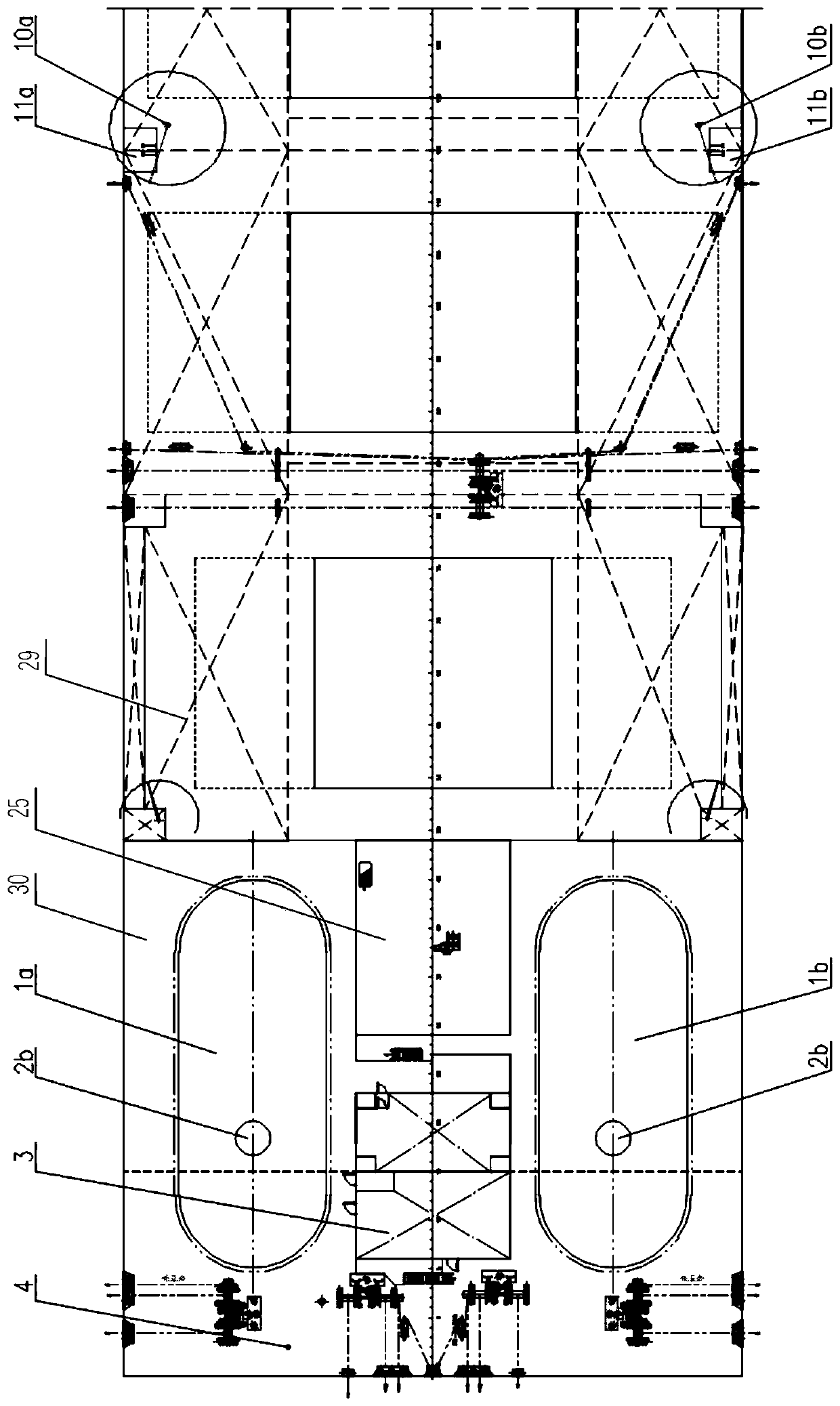

[0095] Such as figure 1 , 2 , 3 and 7, the present embodiment discloses a dual-fuel bulk carrier, including a dual-fuel bulk carrier air supply system, the main deck 26 of the dual-fuel bulk carrier includes a cargo hold area 29 and a stern area 30, the stern area The area 30 includes an extension area 301. The extension area 301 is located on both sides of the stern and extends away from the midship. The side of the stern area 30 close to the cargo hold area 29 is provided with a superstructure 25. The dual-fuel bulk carrier gas supply system include:

[0096] LNG fuel tanks 1a, 1b, the LNG fuel tanks 1a, 1b are arranged above the open stern area 30, and are located on the left and right sides of the superstructure 25;

[0097] Engine room, the engine room is arranged below the main deck 26;

[0098] Gas process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com