Grouting material for underground mine roadway and grouting water control method

A technology of grouting materials and roadways, which is applied in underground chambers, tunnels, tunnel linings, etc., can solve the problems that the grouting effect does not meet the design requirements, and achieve optimized grouting construction technology, economical and reasonable, and good grouting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: The specific process of the grouting water control method for the local underground mine roadway is as follows.

[0029] (1) Project overview: The roadway excavation project in the middle section of the ramp-400m, on a certain day in 2015, when it was constructed to 483.5m along the vein roadway, it encountered a broken zone, and a large amount of bedrock fissure water gushed out, with a water inflow of 21.3m 3 / h. This is the junction of ore and rock. The ore body develops longitudinally along the roadway, and the extrusion deformation and crushing are serious, and the fissures are very developed, accompanied by water gushing from bedrock fissures. The drainage pressure of the local drainage system ensures the safety of shaft construction.

[0030] (2) Construction plan:

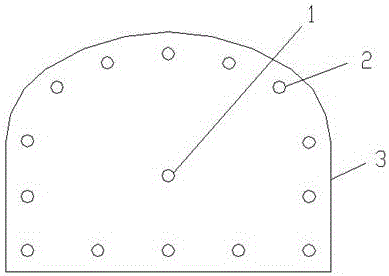

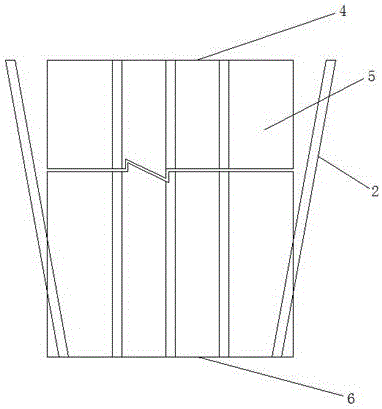

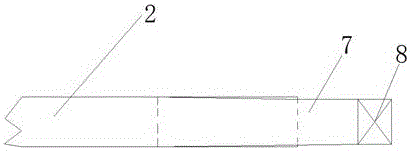

[0031] A. Deep hole grouting method and grouting hole layout: According to the development degree of cracks and the characteristics of large water inflow in this project, both ends ad...

Embodiment 2

[0037] Embodiment 2: The specific process of the grouting water control method for the local underground mine roadway is as follows.

[0038] (1) Project overview: The roadway excavation project in the middle section of the ramp-375m, on a certain day in 2016, when it was constructed to the 104.0m of the double-track transportation roadway, it encountered a broken zone, the surrounding rock was broken, and the cracks developed longitudinally along the roadway, and there were cracks in the bedrock The water gushes out, and the water gushing volume on the working face reaches 24.5m 3 / h. The TRT advanced detection was carried out on the working face, and the results showed that there were three sections of the broken zone, the first section was within the range of 9 meters to 38 meters in front of the working face, the second section was within the range of 41 meters to 58 meters in front of the working face, and the third section was within the range of Within the range of 66 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com