Method for producing beryllium prill using plasma auxiliary rotating electrode

A technology of auxiliary rotation and metal balls, which is applied in the field of beryllium pebble beds, can solve the problems that beryllium metal balls cannot be replaced, the mechanical strength of beryllium beads is poor, and the sphericity of beryllium beads is not good, so that the surface of powder particles is smooth and clean, spherical The effect of good density and monodispersity and narrow powder particle size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

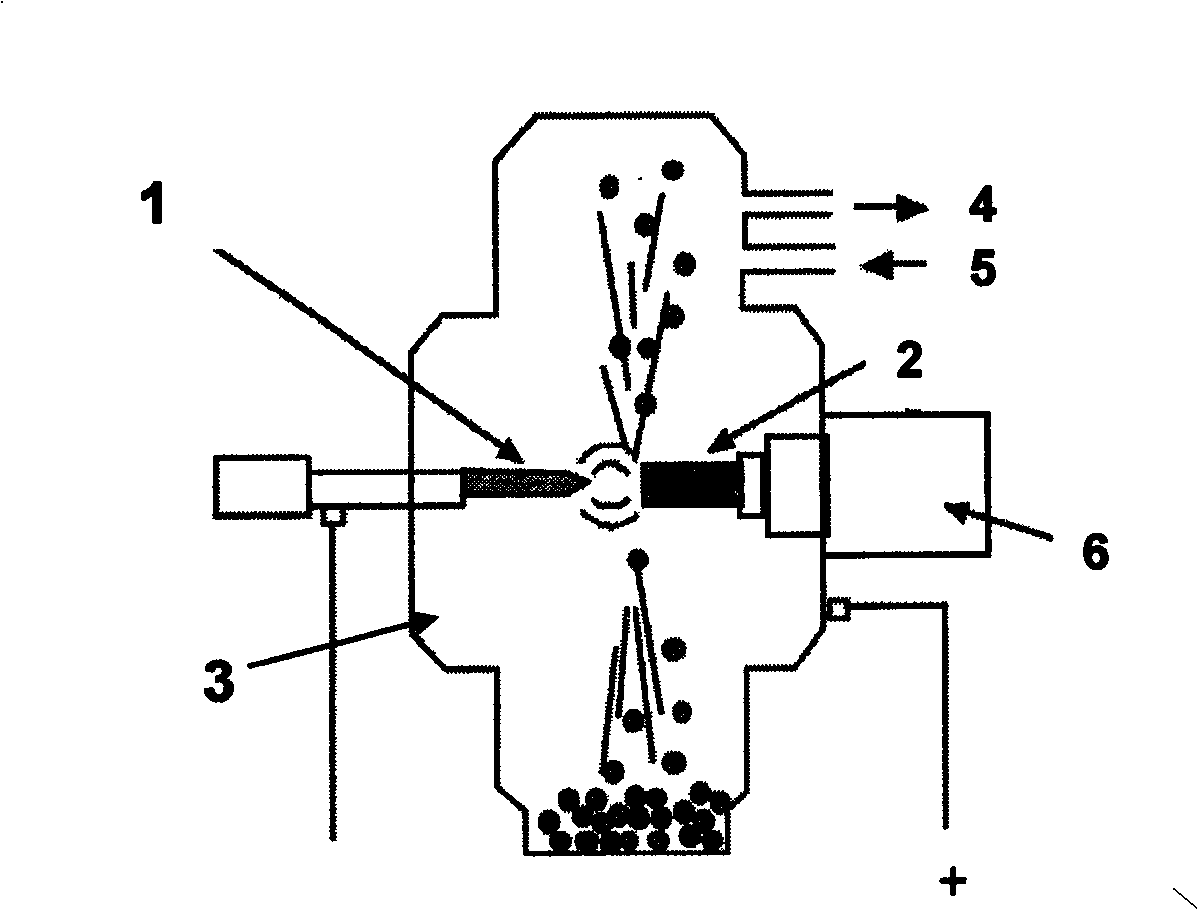

[0022] The method for preparing beryllium metal pellets by using plasma-assisted rotating electrodes is implemented according to the following steps:

[0023] (1) Preparation of anode electrode rods: refining metal beryllium into standard rods, and then finishing it into a plasma gun rotating electrode that can run at a high speed of 8000-10000 revolutions per second to prepare spherical powder. Dynamic seal Electrode rods that run smoothly in the center; the preparation process of electrode rods is: a. Mechanically pulverize beryllium metal raw materials (beryllium blocks or beryllium beads) to obtain beryllium metal powder; b. Pre-process beryllium metal powder through a cold isostatic press Pressing to obtain a rod-shaped blank with a relative density of 60-70%; c, densifying the rod-shaped blank obtained by cold isostatic pressing through a hot isostatic press to obtain a beryllium rod with a relative density greater than 97%; d, heat, etc. The beryllium rods obtained by s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com