Cement emulsion asphalt mortar and its preparing method as well as application in rilroad and in ballastless track of city light rail

A technology of cement-emulsified asphalt and emulsified asphalt, which is applied in the field of building materials, can solve the problems of limited sources, complicated production process, and high price, and achieve the effects of improved irrigation performance, simple production process, and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

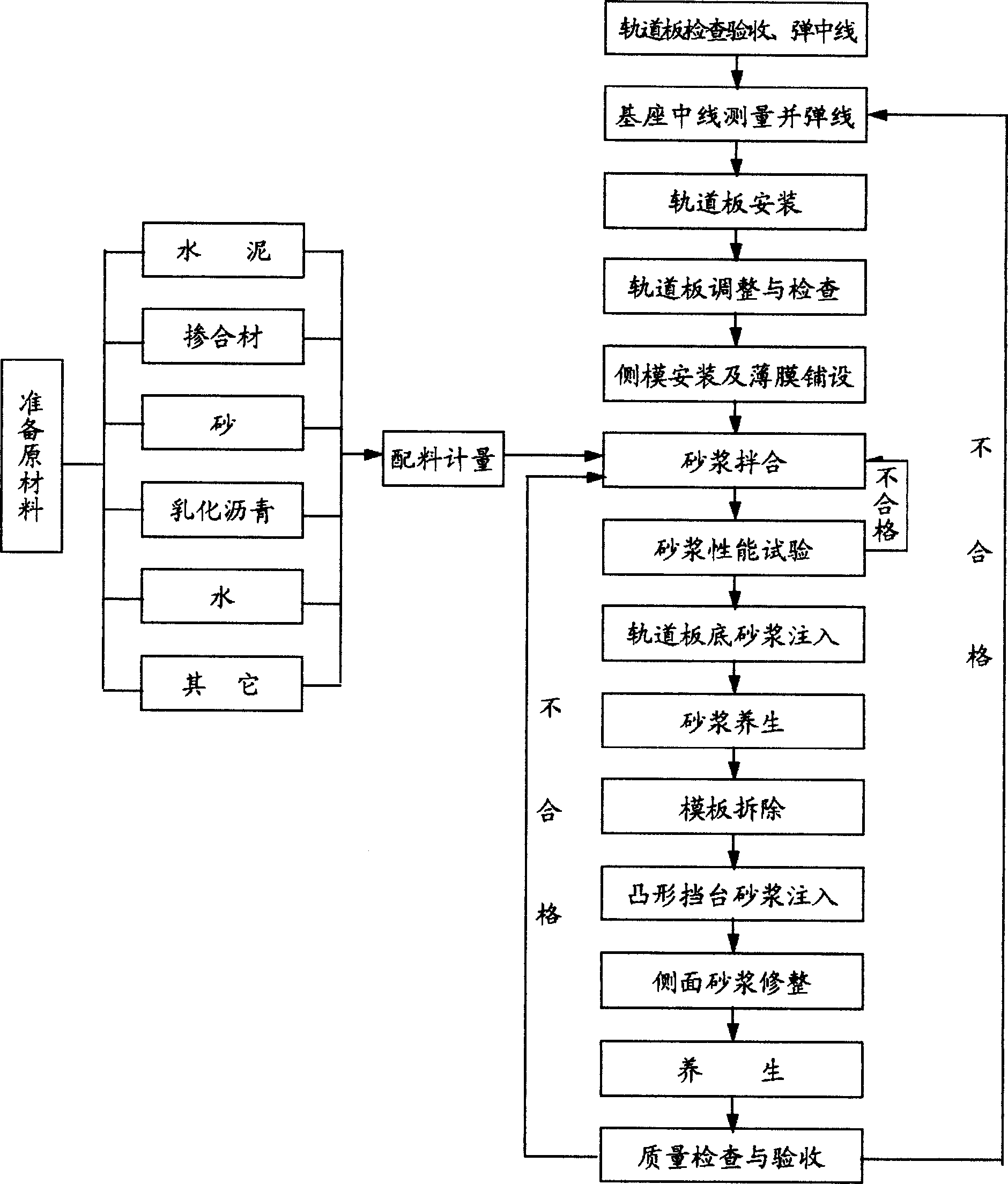

[0036] Real

Embodiment 1

[0038] Mixing ratio of emulsified asphalt:

[0039] Asphalt 600 g octadecyl trimethyl ammonium chloride 10 g

[0040] Polyvinyl alcohol 0.8 g water 390 g

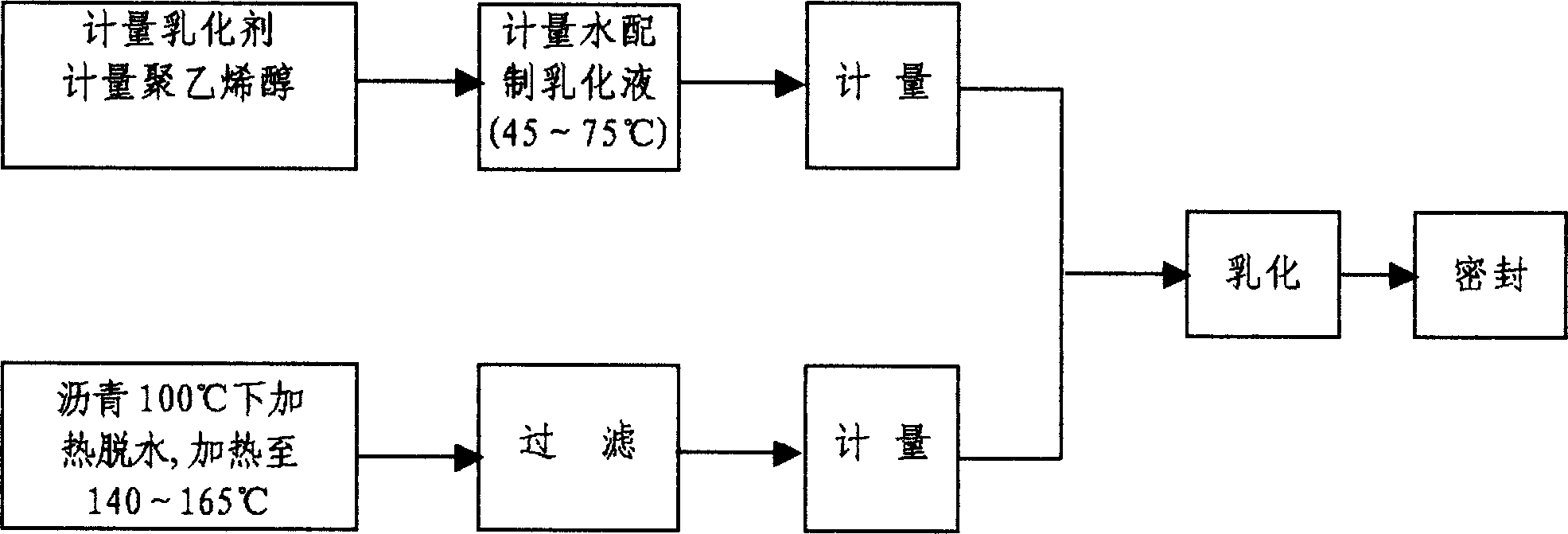

[0041] The preparation process of emulsified asphalt is as follows figure 1 :

[0042] 1. Weigh A-100 bitumen and heat it for dehydration before use. The temperature of bitumen heating and dehydration should be controlled below 100℃. Asphalt should be heated with warm fire to avoid deterioration of asphalt coking. Asphalt must be completely dehydrated, no air bubbles on the surface, and in a calm state. The heating temperature must be controlled at 140°C~165°C before it can be emulsified. It must be filtered with a screen to remove impurities.

[0043] 2. Heat the water to 45℃~75℃.

[0044] 3. Weigh out the emulsifier octadecyl trimethyl ammonium chloride (stir well before use to avoid uneven effective content each time) and stabilizer polyvinyl alcohol.

[0045] 4. Dissolve the emulsifier octadecyl trimethyl ammonium chloride...

Embodiment 2

[0062] Mixing ratio of emulsified asphalt:

[0063] A-70 pitch 600 g cetyl trimethyl ammonium bromide 9 g

[0064] Polyvinyl alcohol 0.7 g water 390 g

[0065] The production process of emulsified asphalt is as described in Example 1.

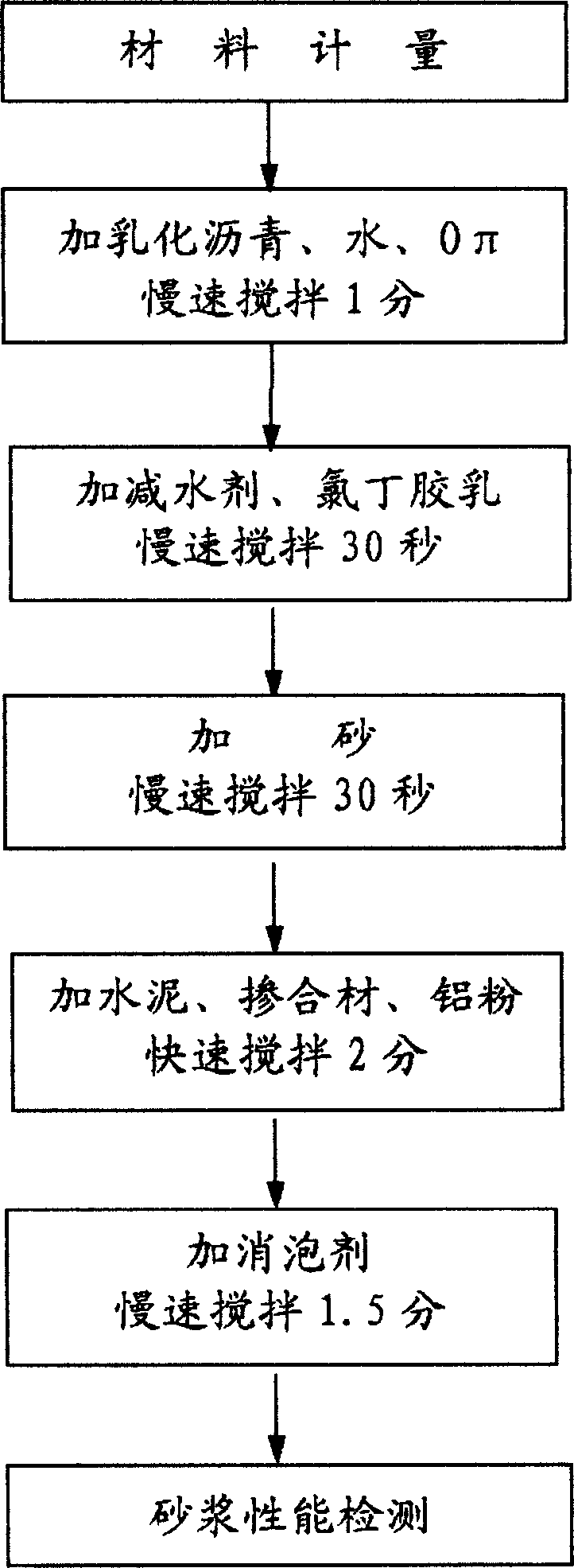

[0066] Preparation of cement emulsified asphalt mortar: (The ratio of raw materials is shown in Example 2 in Table 1)

[0067] The admixture used is a U-shaped concrete expansion agent produced by Wuhan Good New Materials Co., Ltd. in Hubei Province; the water reducing agent used is FFT water reducing agent, and the defoaming agent used is dibutyl phosphate.

[0068] The preparation method and the pouring construction method of the cement emulsified asphalt mortar are the same as in Example 1.

[0069] The composition ratio of the raw materials in Example 3-4 is shown in Table 1. The production process of emulsified asphalt, the preparation method of cement emulsified asphalt mortar, and the pouring construction method are the same as in Example 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com