Efficient alloying method for smelting 38CrMoAl steel

An alloying and high-efficiency technology, applied in the field of iron and steel metallurgy, can solve the problems of reducing the life of the ladle, deteriorating the cleanliness of the molten steel, high gas content and inclusion content of the steel ingot, and ensuring stability, improving cleanliness, and low gas content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

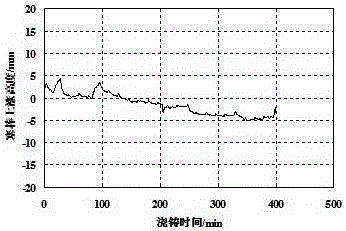

[0034] Five batches of 38CrMoAl steel were continuously produced in a steelmaking workshop. The process flow includes electric arc furnace melting, LF refining, VD vacuum refining, and continuous casting of blooms. The specific steps are as follows:

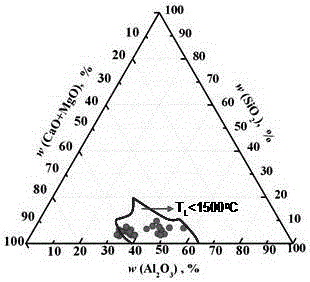

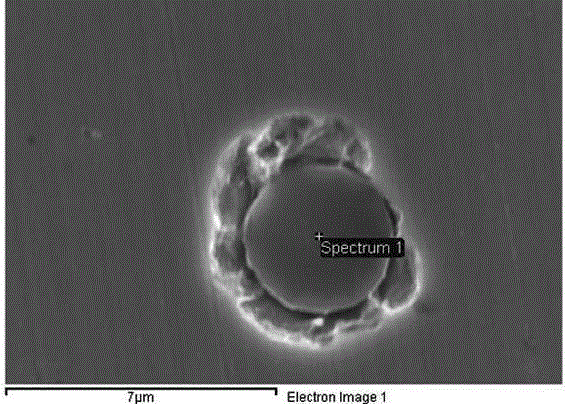

[0035] (1) Electric arc furnace smelting process: The furnace charge is composed of pig iron and scrap steel. The furnace charge is melted by electric arc heating and chemical reaction heat. During the smelting process, active lime is added to form slag. The binary alkalinity of the slag is controlled at 3-5. Most of the oxidized slag is let go, and the steel tapping process follows the order of "aluminum ingot → ferrosilicon → ferromanganese → ferrochrome → ferromolybdenum → pre-melting refining slag and lime" to add alloy and slag for pre-refining. The amount of aluminum ingot added 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com