Bottom power taking self-locking electric bus battery box system capable of quickly changing battery

A technology for electric buses and battery boxes, applied in electric vehicle charging technology, electric power devices, power devices, etc., can solve the problems of deformation of the grasping mechanism, difficult locking and unlocking, welding, etc., and achieve a reliable locking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below through the embodiments and in conjunction with the accompanying drawings.

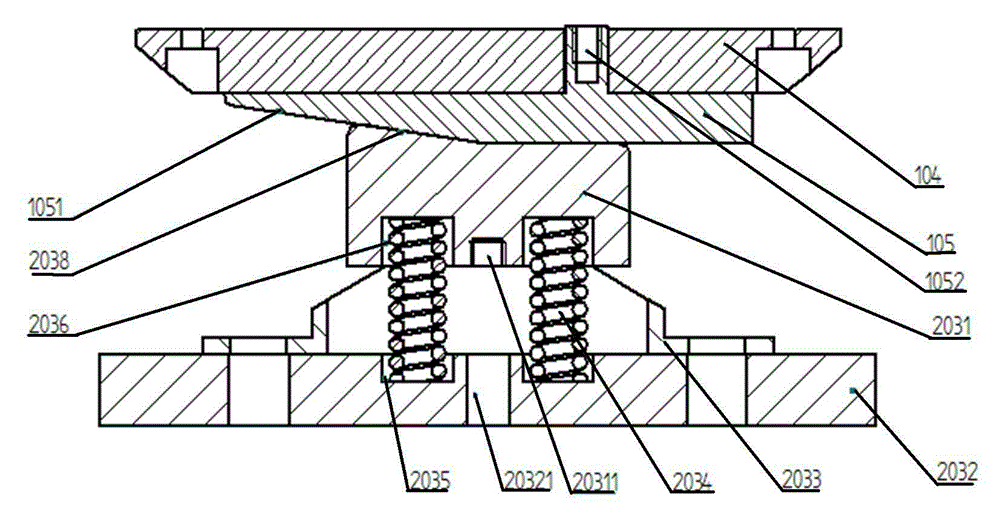

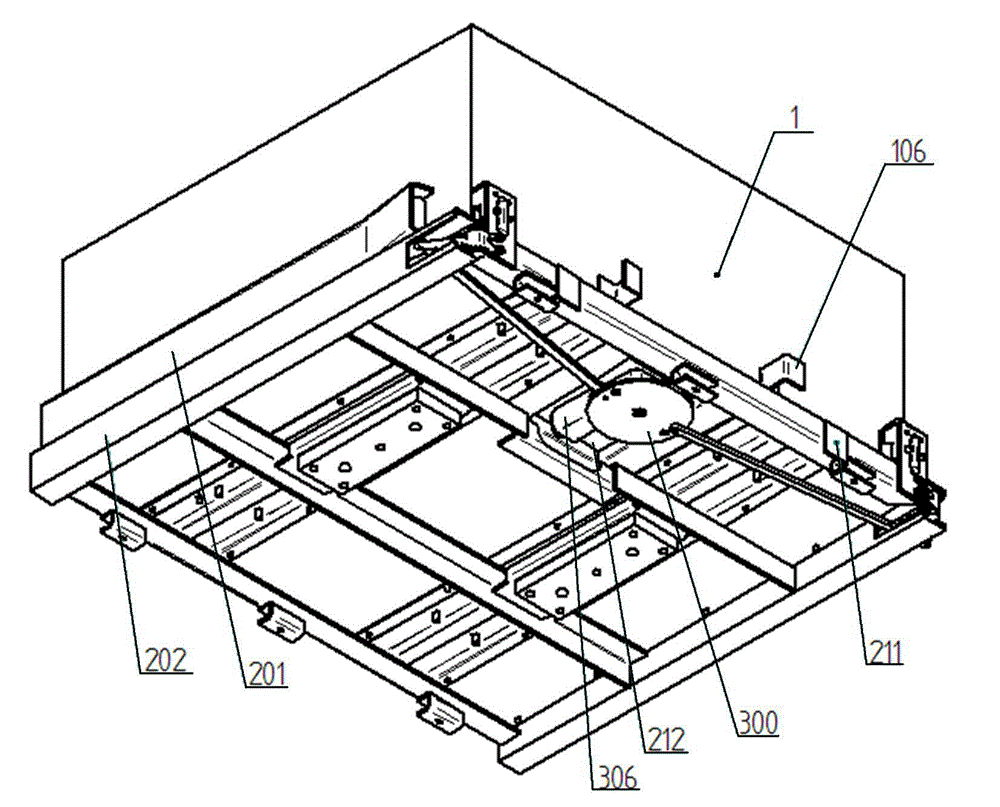

[0049] Such as figure 1 , figure 2 , image 3 As shown, the electric bus battery box system for self-locking and quick battery replacement of the electric bus at the bottom of the present invention includes a battery box 1, a tray 2 for carrying and positioning the battery box and installed on the electric bus, and a tray 2 for installing on the tray 2. The locking and unlocking device 3 for locking the battery box, the mobile device 4 for transporting the battery box, and the grabbing device 5 installed on the mobile device.

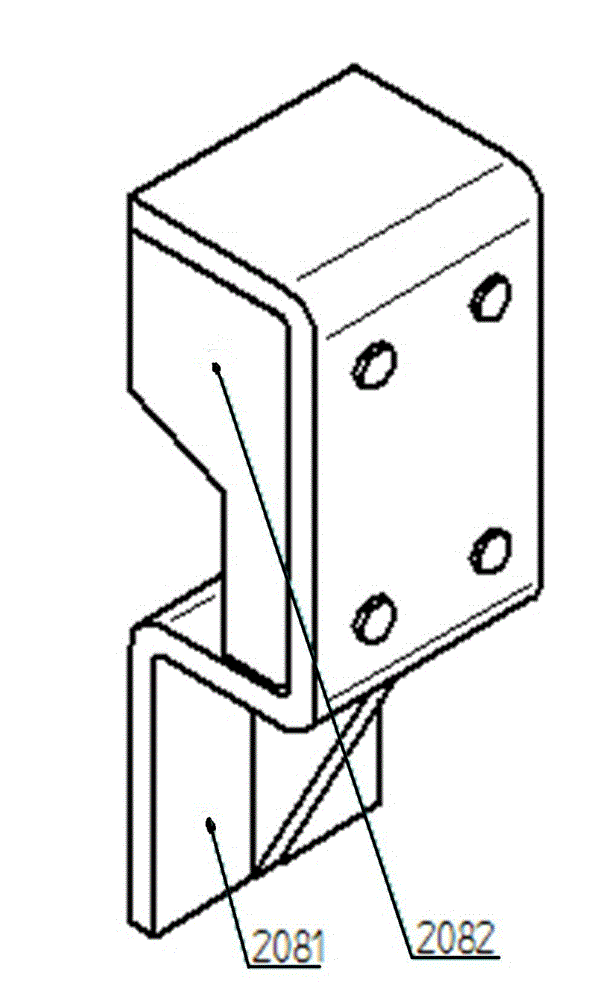

[0050] Such as Figure 4 , Figure 5A , Figure 5B As shown, the battery box 1 includes a box body 101 containing a cell module and a battery management system, wedge-shaped locking blocks 102 installed on both sides of the front end of the box body, and two symmetrical openings located in the middle of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com