MoS2-group self-lubricating wear-resistant corrosion-resistant alloy and preparation method thereof

An anti-corrosion and alloy technology, applied in the field of alloys, can solve the problems of poor wear resistance and corrosion resistance, and achieve the effects of low burning loss of alloy components, easy control of components, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

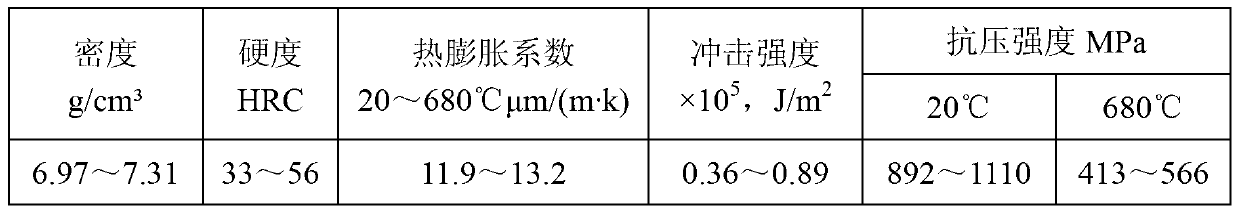

Image

Examples

preparation example Construction

[0026] The above-mentioned MoS 2 The preparation method of the base self-lubricating wear-resistant and corrosion-resistant alloy comprises the following steps:

[0027] Step 1. In a pollution-free environment, weigh C: 0.3-0.4%, N: 0.03-0.08%, Cu: 2-5%, Ni: 8-16%, and MoS respectively according to mass percentage 2 : 2-25%, the balance is aluminum-based, the sum of the mass percentages of the above components is 100%, and then mixed homogeneously with a three-dimensional mixer;

[0028] Step 2, put the homogeneous mixture mixed in step 1 into a molding mold for pre-compression molding, then isostatically press to make the density reach 99.99%, and then sinter under nitrogen environment at a temperature of 1450-1510°C to obtain MoS 2 Based on self-lubricating wear-resistant and corrosion-resistant alloy.

[0029] The composition of the alloy is precisely controlled within the above range because:

[0030] (1) C: Element C mainly interacts with alloying elements Ni, Al, Cu a...

Embodiment 1

[0043] Step 1. In a pollution-free environment, weigh C: 0.3%, Cu: 3%, Ni: 12%, MoS 2 : 20%, the balance is aluminum-based, the mass percentage sum of the above components is 100%, and then mixed homogeneously with a three-dimensional mixer;

[0044] Step 2, put the homogeneous mixture mixed in step 1 into a molding mold for pre-compression molding, and then isostatically press to make the density reach 99.99%, and then sinter in a nitrogen environment at a temperature of 1450°C to obtain MoS 2 Based on self-lubricating wear-resistant and corrosion-resistant alloy.

Embodiment 2

[0046] Step 1. In a pollution-free environment, weigh C: 0.4%, Cu: 5%, Ni: 8%, MoS 2 : 25%, the balance is aluminum-based, the mass percentage sum of the above-mentioned components is 100%, and then mixed homogeneously with a three-dimensional mixer;

[0047] Step 2, put the homogeneous mixture mixed in step 1 into a molding mold for pre-compression molding, and then isostatically press to make the density reach 99.99%, and then sinter in a nitrogen environment at a temperature of 1510°C to obtain MoS 2 Based on self-lubricating wear-resistant and corrosion-resistant alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com