A kind of low-friction self-lubricating acrylic resin and its preparation method and application, low-friction self-lubricating marine antifouling coating

An acrylic resin, marine antifouling technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of low substrate adhesion, poor durability, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

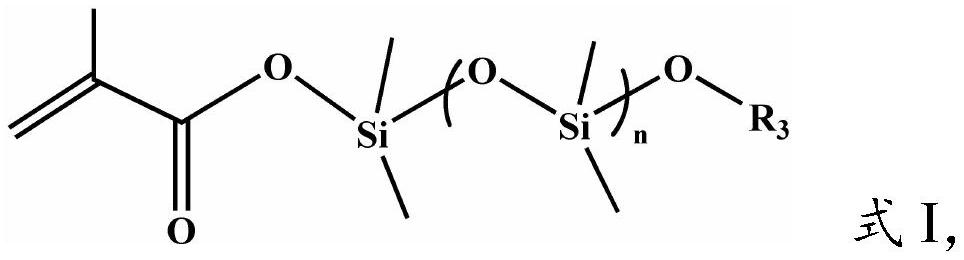

[0065] In the present invention, the preparation method of the polymerizable silicone oil monomer preferably includes the following steps:

[0066] Mixing hydroxypropyl silicone oil, isocyanoethyl methacrylate and dibutyltin dilaurate, and carrying out a catalytic reaction to obtain the polymerizable silicone oil monomer.

[0067] In the present invention, the molecular weight of the hydroxypropyl silicone oil is preferably 1500-2500, more preferably 1600-2400. In the present invention, the mixing of the hydroxypropyl silicone oil, isocyanoethyl methacrylate and dibutyltin dilaurate is preferably after the hydroxypropyl silicone oil and dibutyltin dilaurate are mixed, and then added to the resulting mixing system Add isocyanoethyl methacrylate. Before the hydroxypropyl silicone oil is mixed, the present invention preferably performs drying treatment on the hydroxypropyl silicone oil; the temperature of the drying treatment is preferably 120° C.; the time is preferably 4 hours...

Embodiment 1

[0132] Preparation of polymerizable silicone oil monomer: Dry hydroxypropyl silicone oil with a molecular weight of 2000 at 120°C for 4 hours under vacuum and decompression, and mix 0.1mol of dried hydroxypropyl silicone oil with 0.3g of dibutyltin dilaurate , the temperature was raised to 40°C, and 0.1mol of isocyanoethyl methacrylate was dropped into the reaction system at a rate of 2 drops / s at 40°C with a stirring rate of 600rpm, and the catalytic reaction was carried out after the dropwise addition was completed 4h, obtain polymerizable silicone oil monomer;

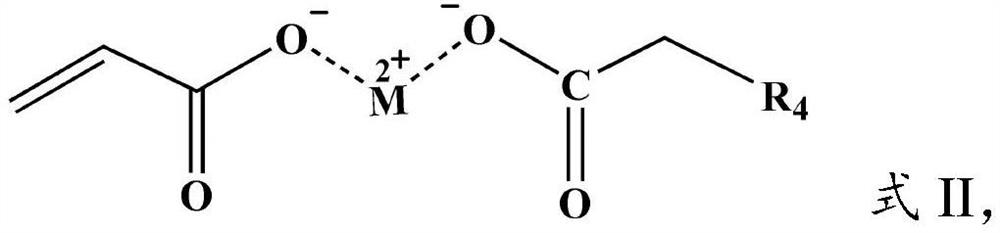

[0133] The preparation of unsaturated organic acid divalent metal ion salt monomer: the Zn(OH) of 8.2g 2 Mix with 15g ethylene glycol methyl ether to obtain the ethylene glycol methyl ether solution of zinc hydroxide; 6g acrylic acid, 10.2g benzoic acid and 20g ethylene glycol methyl ether are mixed uniformly to obtain a drop solution; Under the condition of 300rpm, the dropping liquid is added dropwise in the ethy...

Embodiment 2

[0136] Prepare polymerizable silicone oil monomer and unsaturated organic acid divalent metal ion salt monomer according to the method of Example 1;

[0137] Mix 10g ethylene glycol methyl ether, 10g xylene, 8g propylene glycol methyl ether acetate, 10g methyl methacrylate, 5g butyl acrylate, 10g ethyl acrylate and 6g polymerizable silicone oil monomer to obtain A liquid; 3-[N,N-dimethyl-[2-(2-methylprop-2-enoyloxy)ethyl]ammonium]propane-1-sulfonic acid inner salt, 15g ethylene glycol methyl ether , 10g propylene glycol methyl ether acetate, 8g xylene, 75g zinc acrylate monomer solution, 6g polymerizable silicone oil monomer, 10g 2-(perfluorooctyl) ethyl methacrylate, 25g methyl methacrylate , 4g of butyl acrylate, 11g of ethyl acrylate and 2g of azobisisobutyronitrile were stirred and mixed evenly to obtain liquid B; at 90°C and a stirring rate of 300rpm, liquid B was added dropwise to A at a rate of 1 drop / s. After the dropwise addition, keep warm for 3 hours to carry out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com