Fuel pump

A fuel pump, high-pressure fuel pump technology, applied in the direction of fuel injection pump, pump, fuel injection device, etc., can solve problems such as mechanical failure of pump piston fuel pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

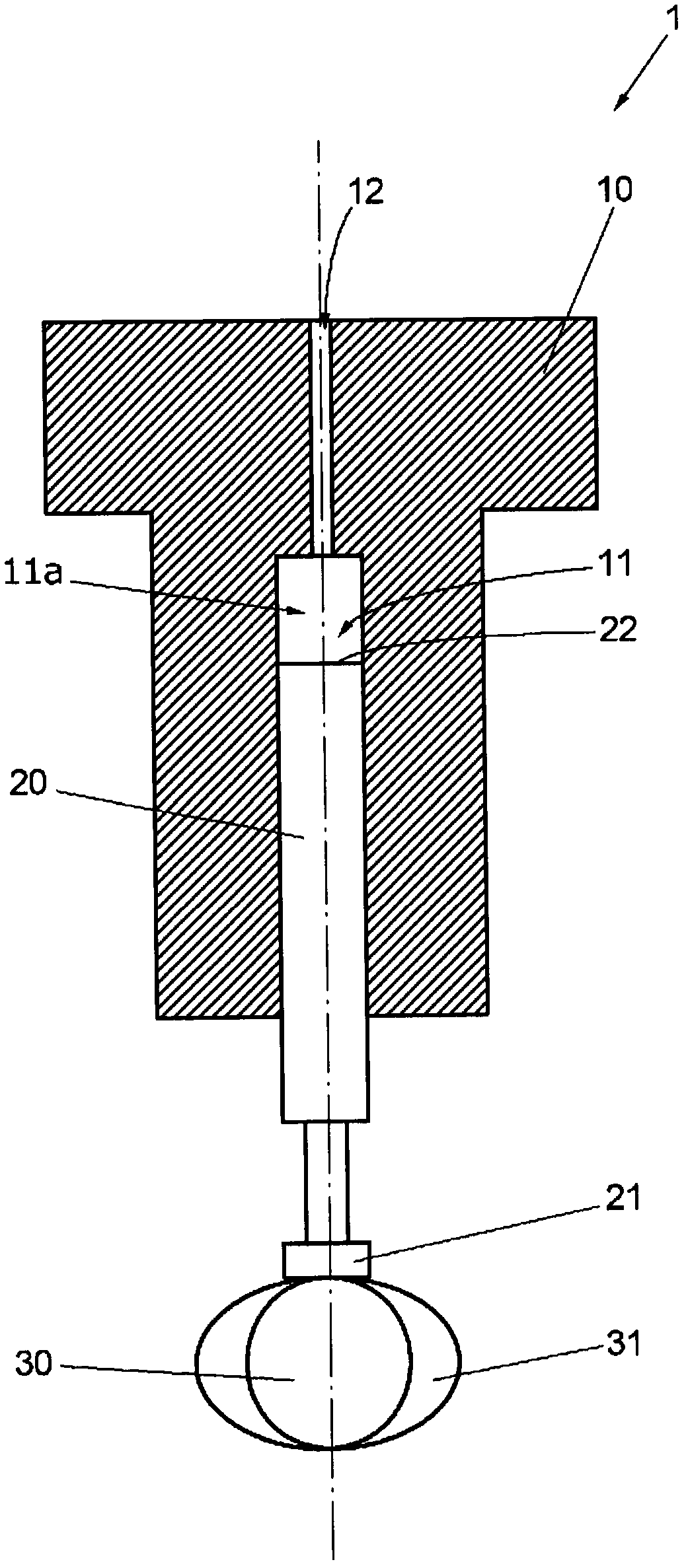

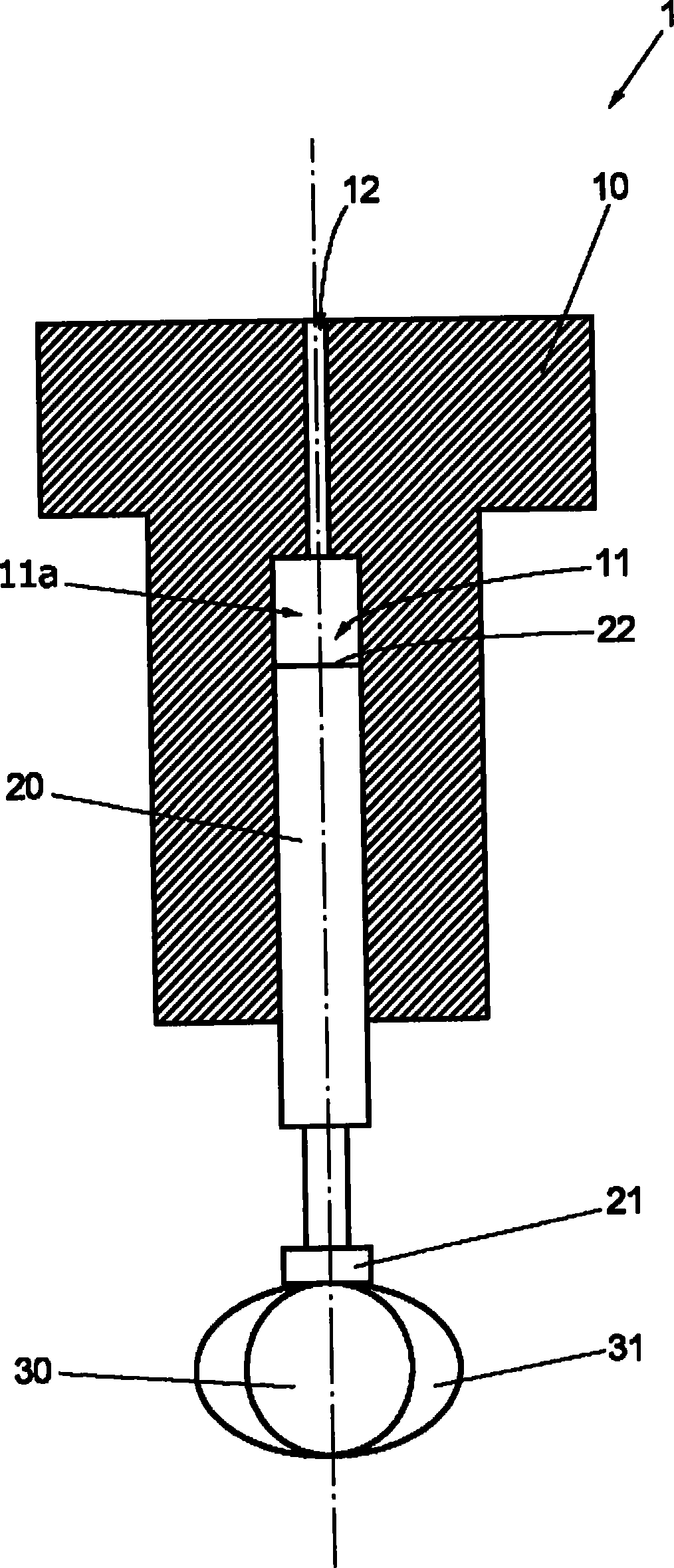

[0021] Such as figure 1 As shown, the fuel pump 1 according to the invention is here preferably configured as a high-pressure fuel pump (not completely shown) of a common rail fuel system, which has a pump cylinder 10 and a recess 11 in the pump cylinder 10 that can The movably mounted or guided pump piston 20 .

[0022] The pump piston 20 is controlled by at least one cam 31 arranged on a rotationally driven shaft 30 so as to be movable up and down in the pump cylinder 10 , wherein the fuel is moved down by the pump piston 20 through the fuel formed in the pump cylinder 10 The channel 12 is sucked into the area not occupied by the pump piston 20 or the pump chamber 11a of the recess 11 of the pump cylinder 10, and the sucked fuel is moved upward by the pump piston 20, passing through the fuel channel 12 and the not shown intermediate The storage device (for example, a delivery line here) is fed to a consumer (not shown), for example an injection valve of a fuel system.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com