Preparation method of porous tea residue biochar with high specific surface area

A high specific surface area, biochar technology, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve problems such as limited membrane blockage and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

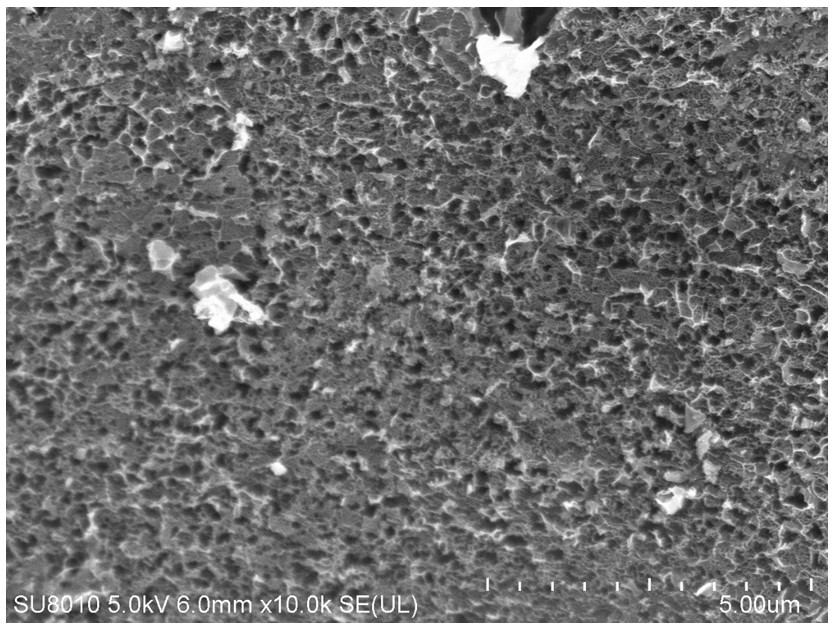

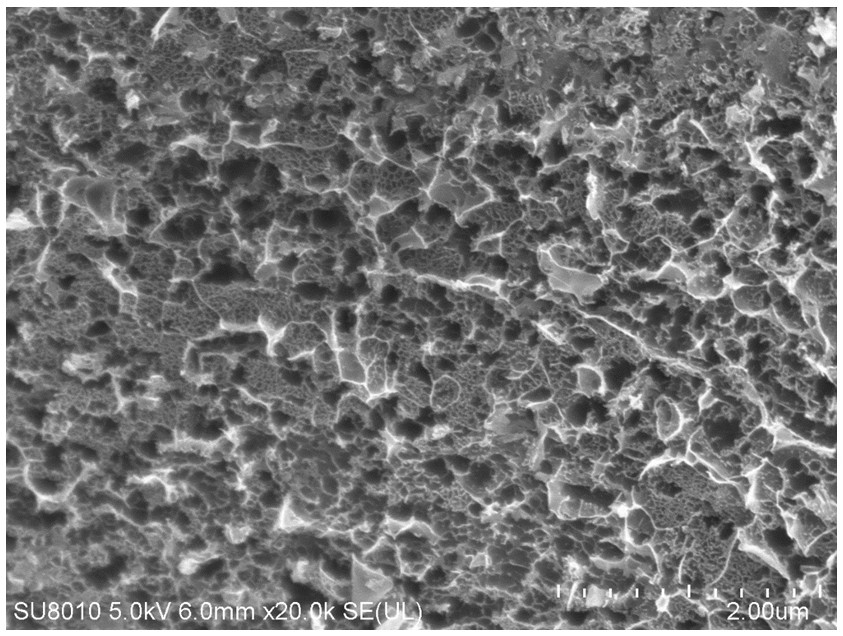

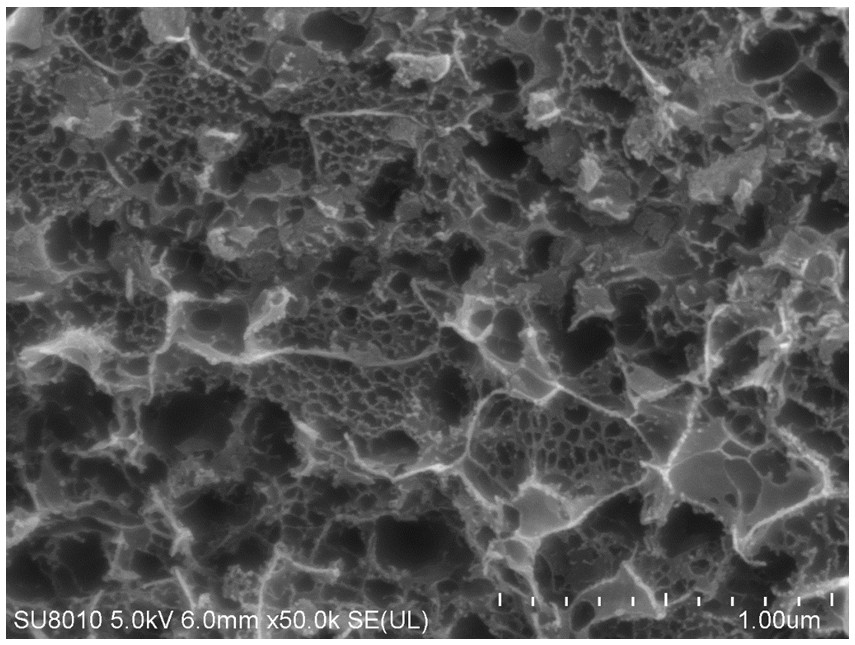

Image

Examples

Embodiment 1

[0038] The concrete preparation operation steps of tea dregs biochar of a kind of porous high specific surface area are as follows:

[0039] (1) Raw material pretreatment

[0040] The discarded tea dregs taken from the tea factory were washed with water to remove impurities. After washing, the tea dregs were put into a blast drying oven for drying. The temperature of the blast drying oven was 100°C for 10 hours. 60 mesh sieve, save for future use.

[0041] (2) Hydrothermal treatment

[0042] Mix 3 grams of tea residue and 50 ml of pure water into a hydrothermal reaction kettle, react at 200°C for 8 hours, and separate the solid and liquid to obtain hydrothermal charcoal; the hydrothermal charcoal is washed three times with absolute ethanol, and the hydrothermal charcoal and The ratio of water to ethanol is 1:20; it is dried in a blast drying oven at a temperature of 100°C for 10 hours to obtain hydrothermal charcoal.

[0043] (3) Modifier impregnation treatment

[0044] Mix ...

Embodiment 2

[0052] The concrete preparation operation steps of tea dregs biochar of a kind of porous high specific surface area are as follows:

[0053] (1) Raw material pretreatment

[0054] The waste tea dregs taken from the tea factory were washed with water to remove impurities. After washing, the tea dregs were put into a blast drying oven for drying. The temperature of the blast drying oven was 105°C and the time was 15 hours. 70 mesh sieves are stored for future use.

[0055] (2) Hydrothermal treatment

[0056] Mix 4 grams of tea residue and 65 ml of pure water into a hydrothermal reaction kettle, react at 200°C for 9 hours, separate solid and liquid to obtain hydrothermal charcoal, wash hydrothermal charcoal with absolute ethanol three times, hydrothermal charcoal and anhydrous The ratio of water to ethanol is 1:20, and it is dried in a blast drying oven at a temperature of 105°C for 15 hours to obtain hydrothermal charcoal.

[0057] (3) Modifier impregnation treatment

[0058...

Embodiment 3

[0065] The concrete preparation operation steps of tea dregs biochar of a kind of porous high specific surface area are as follows:

[0066] (1) Raw material pretreatment

[0067] The discarded tea dregs taken from the tea factory were washed with water to remove impurities. After washing, the tea dregs were put into a blast drying oven for drying. The temperature of the blast drying oven was 105°C for 24 hours. 80 mesh sieves are stored for future use.

[0068] (2) Hydrothermal treatment

[0069] Mix 5 grams of tea residue and 80 milliliters of pure water into a hydrothermal reaction kettle, react at 200°C for 10 hours, separate solid and liquid to obtain hydrothermal charcoal, wash hydrothermal charcoal with absolute ethanol three times, hydrothermal charcoal and The ratio of water to ethanol is 1:20, and it is dried in a blast drying oven at a temperature of 105°C for 24 hours to obtain hydrothermal charcoal.

[0070] (3) Modifier impregnation treatment

[0071] Mix hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com