A continuous carbon fiber sucker rod with wear-resistant protective layer and its preparation method

A sucker rod and carbon fiber technology, used in drill pipes, earth-moving drilling, drilling equipment, etc., can solve the problems of continuous sucker rod eccentric wear, etc., to ensure continuity, prolong service life, and improve anti-eccentric wear characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

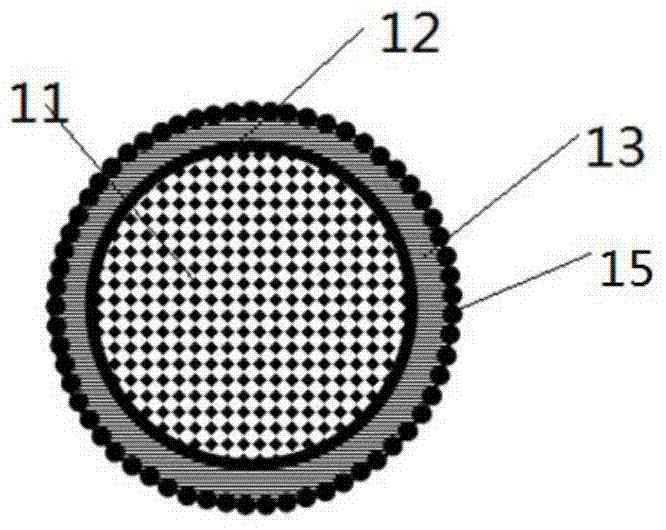

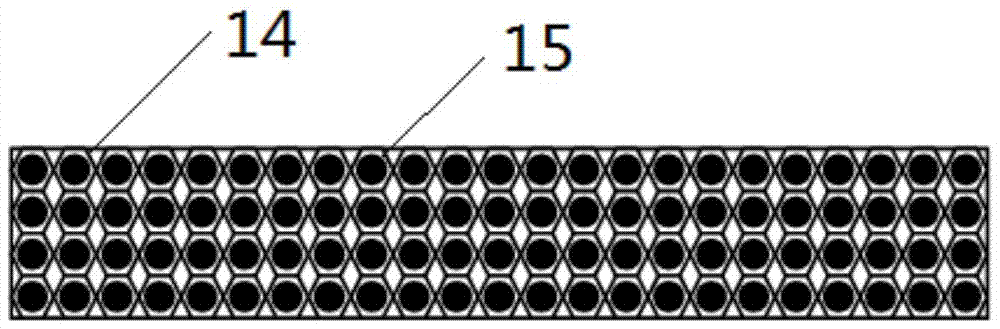

[0042] Preparation of wear-resistant layer prepreg tape: the reinforcing fiber used in the preparation of prepreg narrow tape is a hybrid fiber of basalt fiber and alumina fiber, the ratio of the two fibers is 2:1, and the reinforcing fiber fabric adopts "mesh cloth / unidirectional cloth / mesh The resin matrix used is polyurethane resin, and the polyurethane resin is made into a film in advance, and silicon carbide hard particles with a total content of 10% of the prepreg tape are pre-dispersed into the film, and the particle size is 0.5 microns. Lay the resin film of pre-mixed silicon carbide hard particles on the release paper, and apply the release paper with the resin film on the upper and lower surfaces of the laminated structure. The fiber fabric forms a prepreg tape, the final resin content of the prepreg tape is 40%, and the width of the prepreg tape is 90mm.

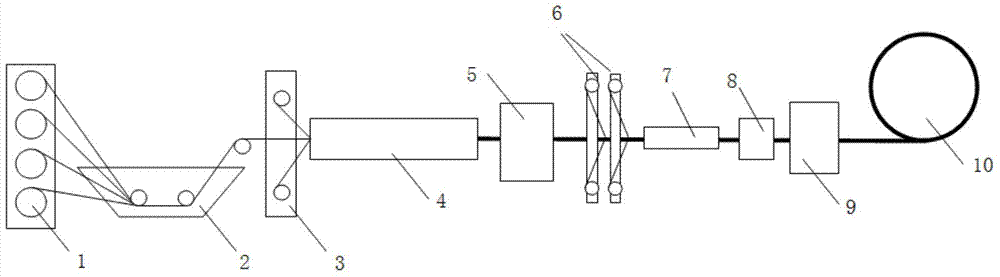

[0043] like figure 1 As shown, the preparation of a new type of continuous carbon fiber composite sucker rod w...

Embodiment 2

[0045] Preparation of wear-resistant protective layer prepreg tape: the reinforcing fiber used in the preparation of prepreg narrow tape is a hybrid fiber of silicon carbide fiber and alumina fiber, the ratio of the two fibers is 4:1, and the "mesh cloth / plain weave / twill cloth / mesh cloth "Laminated structure, the resin matrix used is polyurethane resin, and the polyurethane resin is pre-made into a film, which is pre-dispersed into the film with silicon carbide hard particles with a total content of 15% of the prepreg tape, and the particle size is 0.4 microns. Lay the resin film with pre-mixed hard particles on the release paper, apply the release paper with the resin film on the upper and lower surfaces of the laminated structure, and combine the film and the fiber fabric by continuous hot-melt impregnation A prepreg tape is formed, the final resin content of the prepreg tape is 35%, and the width of the prepreg tape is 10 mm.

[0046] Preparation of new continuous carbon f...

Embodiment 3

[0048] Preparation of wear-resistant protective layer prepreg tape: the reinforcing fiber used in the preparation of prepreg narrow tape is a hybrid fiber of silicon carbide fiber and basalt fiber, the ratio of the two fibers is 1:3, and the "mesh cloth / plain cloth / satin cloth / mesh cloth Cloth” laminated structure, the resin matrix used is polyethylene resin, the polyethylene resin is made into a film in advance, and the film is pre-dispersed into the aluminum oxide hard particles with a total content of 15% of the prepreg tape, and the particle size is 0.2 microns . Lay the resin film with pre-mixed hard particles on the release paper, apply the release paper with the resin film on the upper and lower surfaces of the laminated structure, and combine the film and the fiber fabric by continuous hot-melt impregnation A prepreg tape was formed, the final resin content of the prepreg tape was 33%, and the width of the prepreg tape was 30 mm.

[0049] Preparation of new continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com