Ultrahigh pressure three-plunger water pump

An ultra-high pressure and plunger technology, applied in the direction of pumps, multi-cylinder pumps, liquid displacement machinery, etc., can solve problems such as water leakage, poor sealing, and low work efficiency, and achieve improved service life, long service life, and self-lubricating Good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

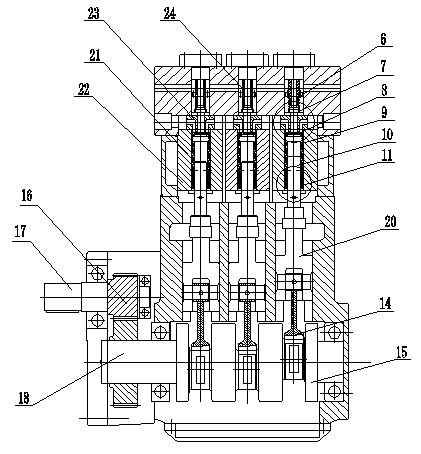

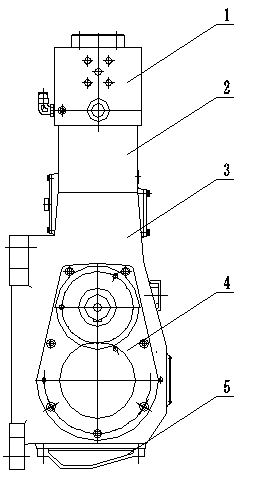

[0011] The invention points of the present invention will be described in detail below in conjunction with the accompanying drawings.

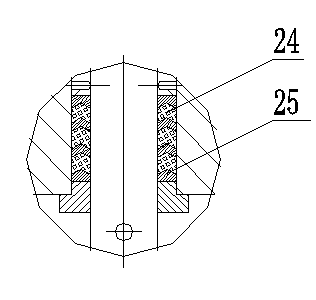

[0012] The technical solutions adopted by the present invention to solve the technical problems are as follows: 1. A combined seal with a special structure is installed between the ceramic plunger 10 and the cylinder 22. The seal is composed of a four-layer sponge-type ceramic spacer 25 and a three-layer ultra-high molecular PE (polymer polyethylene board) sealing body 24. The sealing body has high mechanical strength, low thermal expansion coefficient, excellent self-lubrication and good self-cooling effect, thereby ensuring a long service life and good sealing characteristics. 2. Both the suction valve plate 8 and the drain valve plate 7 are made of heat-resistant stainless steel substrate, ceramic plated on the surface, and precision ground structure. This type of valve disc has excellent wear resistance and minimal thermal deformation, has g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com