Temperature controlled valve core

A temperature control valve and valve core technology, applied in multi-way valves, safety valves, balance valves, etc., can solve the problems of difficult to control water flow, rapid changes in water flow, and difficult to accurately adjust and set temperature, and achieve stable constant temperature effect. , The effect of accurate temperature setting and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

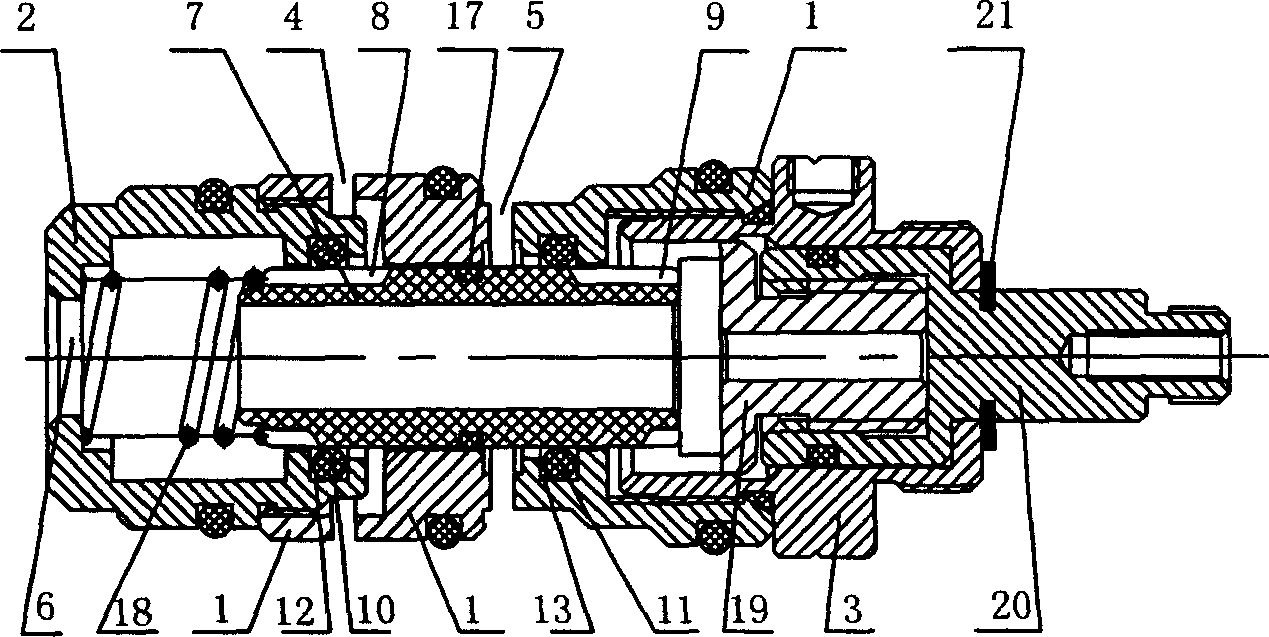

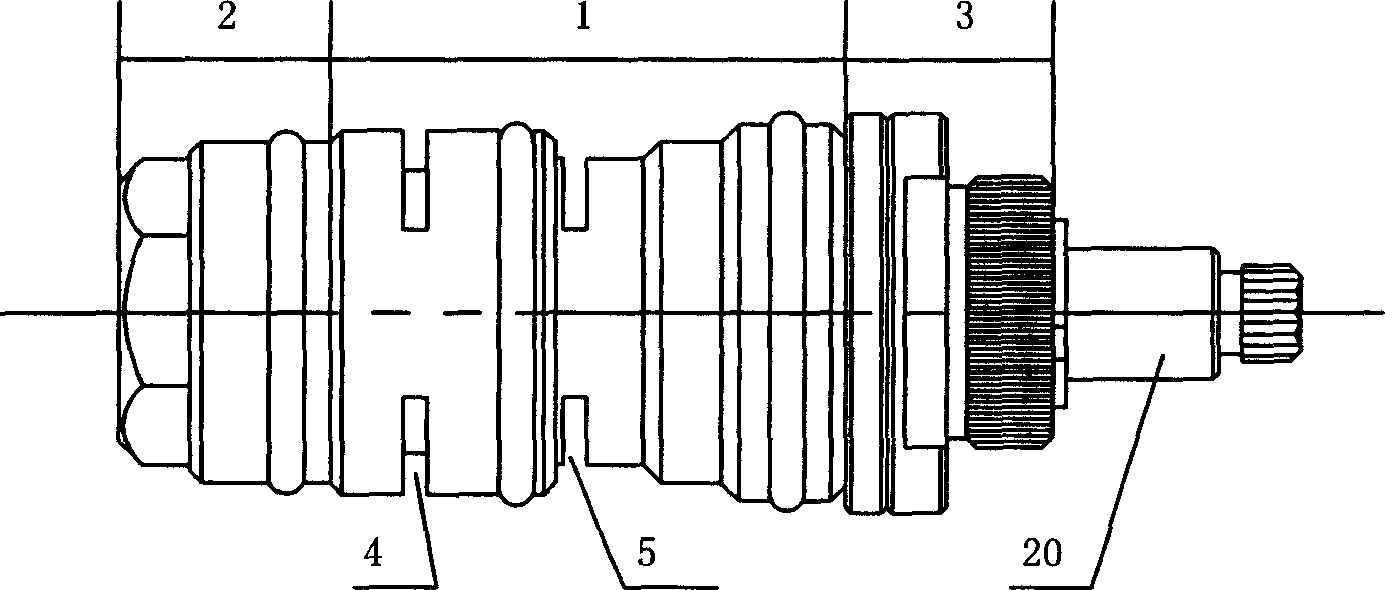

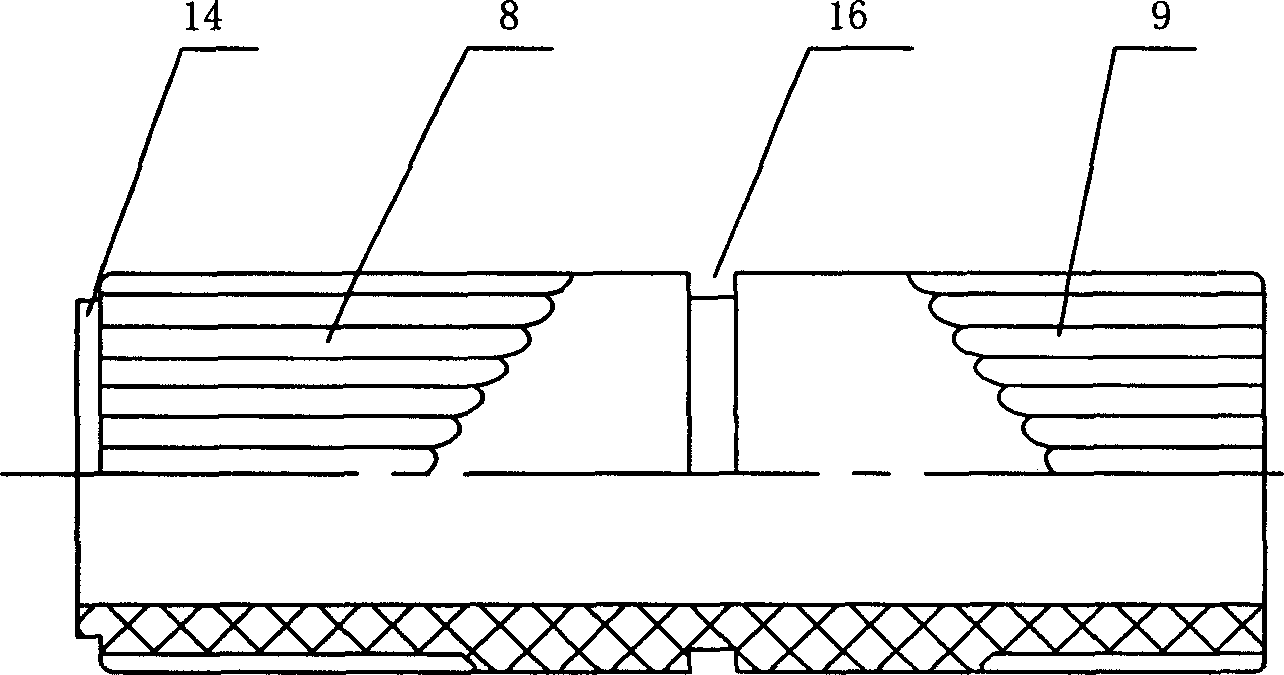

[0035] See figure 1 , figure 2 , a temperature control valve core, including a valve core sleeve composed of a middle sleeve 1, a water outlet sleeve 2 threaded to one end of the middle sleeve 1, and a pressure sleeve 3 threaded to the other end of the middle sleeve 1. The first water inlet 4 (i.e. the hot water channel) and the second water inlet 5 (i.e. the cold water channel) are set on the cover 1, the water outlet 6 (i.e. the mixed water channel) is arranged on the water outlet cover 2, and the middle cover 1 is equipped with The spool inner core 7, the main body of the spool inner core 7 is a hollow cylinder, the spool inner core 7 is limited by the inner core spring 18 and the abutment head 19, the abutment head 19 cooperates with the adjustment screw 20 through threads, and the adjustment screw 20 passes through The pressure sleeve 3 is also clamped by the collar 21, and one end of the inner core spring 18 is pressed against the water outlet sleeve 2, and the other e...

Embodiment 2

[0040] See Figure 7 , the difference between this embodiment and the first embodiment lies in the structure of the notch 15, the notch 15 is another deformation of the protrusion 14, which is used to cooperate with the outer circumference of the inner core spring 18, and its function is the same as image 3 The effect of the protrusion 14 in is exactly the same.

Embodiment 3

[0042] See Figure 8 The difference between this embodiment and the first embodiment is that there are only two first through-slots 8 and two second through-slots 9, the lengths of the two first through-slots 8 are different, and the lengths of the two second through-slots 9 are different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com