Multifunctional linkage device integrating sewage time-sharing sampling and permeation coefficient testing and working method of multifunctional linkage device

A technology of water permeability coefficient and linkage device, which is used in sampling devices, measuring devices, permeability/surface area analysis, etc., can solve the problems of wasting water resources, difficult to measure, and difficult to stabilize water pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

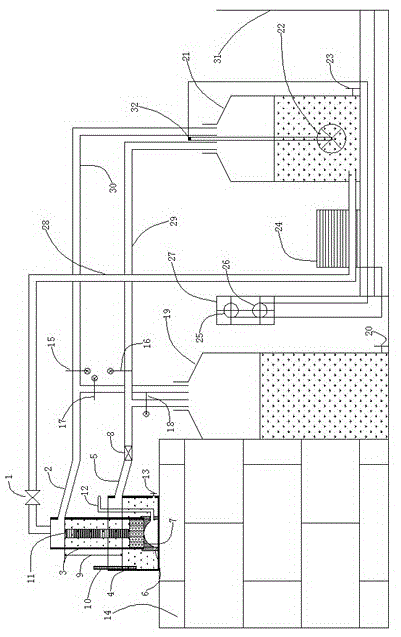

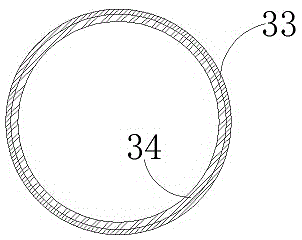

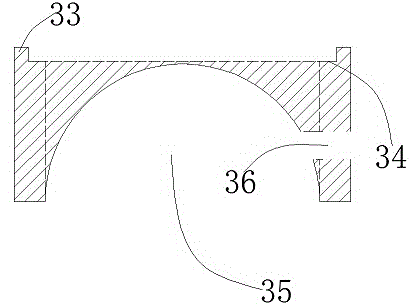

[0096] like figure 1 , 2 , Shown in 3, a kind of multifunctional linkage device that collects time-divided sampling and water permeability test as one, the main components are water supply channel 1; cylinder overflow port 2; water cylinder 3; overflow tank 4; tank overflow Orifice 5; sample bracket 6; sample 7; flow meter 8; water level difference 9; electronic thermometer 10; Control valve 15; second drainage control valve 16; third drainage control valve 17; fourth drainage control valve 18; drainage bucket 19; drainage bucket can control water discharge valve 20; working bucket 21; propeller 22; 23; water pump 24; water pump electric control 25; propeller electric control 26; power switch 27; water supply conduit 28; first drainage conduit 29; second drainage conduit 30; workbench B31; These components belong to two parts, named Apparatus A and Apparatus B respectively.

[0097] The shape and connection method of each part of device A are as follows: The overflow tank 4...

Embodiment 2

[0101] Sewage time-sharing sampling and water permeability test are carried out at the same time, simulating the environment of sample 7 filtering sewage for a long time. First close the working bucket to control the drain valve 23, put 10 parts of quality impurities and 90 parts of quality clear water into the working bucket according to a certain ratio, turn on the power, turn on the power switch 27, adjust the propeller electric control 26, make the propeller 22 with a certain Rotate at a certain speed to fully mix the sewage in the working bucket 21. At this time, the concentration of the sewage in the bucket remains constant at 10%. Closing the overflow tank can control the drain valve 13, the third drain control valve 17 and the fourth drain control valve 18. The first drain control valve 15 and the second drain control valve 16 are opened, and the water discharged from the cylinder overflow port 2 and the tank overflow port 5 in the device A flows to the working bucket ...

Embodiment 3

[0127] A method of using a multi-functional linkage device that integrates time-collecting sewage water sampling and permeability coefficient testing:

[0128] (1) Single measurement of permeability coefficient. The test water quality is clear water, and the instruments used include device A, water pump 24 and working bucket 21. The specific operation steps are as follows:

[0129] A. Fill most of the bucket of water into the working bucket 21, the temperature is controlled at 20±3°C, and the water discharge valve 23 can be controlled by closing the working bucket. Prepare a stopwatch with an accuracy of 1s. Prepare a vernier caliper with a division value of 1mm and a range greater than 100mm. Prepare three cylinders with a diameter D of 100 mm and a thickness L of 50 mm as samples and mark them.

[0130] B. Use a vernier caliper to measure the diameter D and thickness L of the cylindrical sample, measure 3 times respectively, and take the average value. The result is accur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com