Water-feeding pump system driven by high-speed synchronous motor

A high-speed synchronous, electric motor technology, applied in the direction of machines/engines, pumps, pump devices, etc., can solve the problem of increasing the heat consumption of steam turbine generator sets, and achieve the effects of light weight, low consumption, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

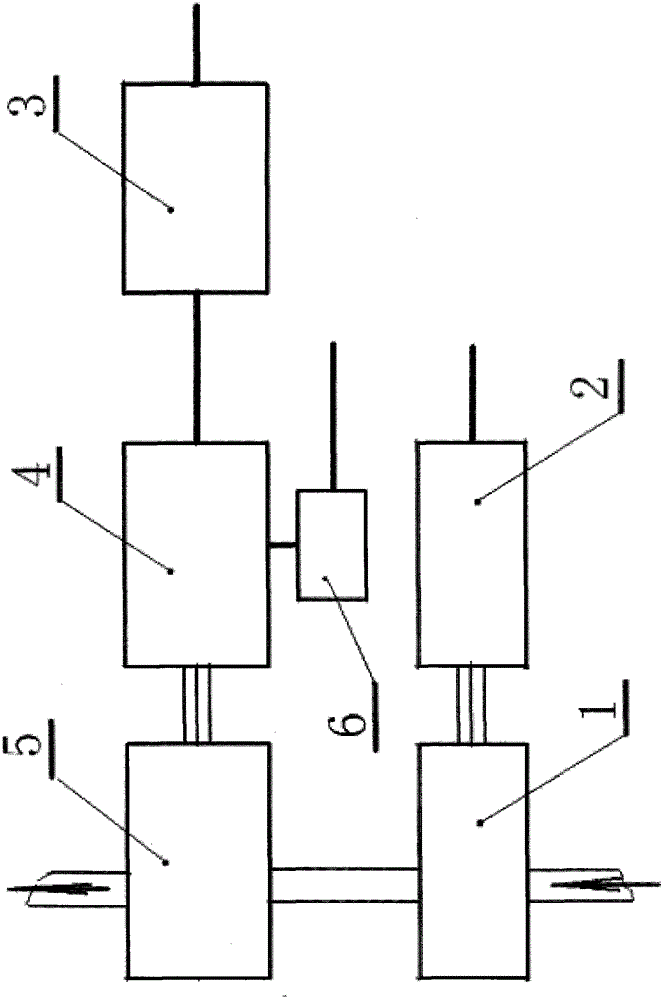

[0031] Combine now figure 1 Take a 1000MW class secondary reheat power station with main steam temperature / primary reheat steam temperature / secondary reheat steam temperature of 605°C / 623°C / 623°C, main steam pressure of 32.45MPa, and main steam flow rate of 2746t / h A boiler is taken as an example to illustrate the preferred way of implementing the invention.

[0032] The feedwater pump system driven by a high-speed synchronous motor of the present invention includes a low-speed pre-pump (1), a low-speed pre-pump motor (2), an intermediate frequency variable frequency power supply (3), a high-speed synchronous motor (4), and a high-speed feedwater pump (5) ), the static excitation device (6); the intermediate frequency variable frequency power supply (3) is connected to the 3-phase 10kV, 50Hz factory busbar, and outputs 3-phase 1Hz to 100Hz AC with good waveform, and the output voltage increases with the increase of the output frequency. When the output frequency reaches 100Hz...

Embodiment 2

[0038] Combine now figure 1Taking a 1000MW class, main steam temperature / reheat steam temperature of 605°C / 623°C, main steam pressure of 29.4MPa, main steam flow rate of 3033t / h double reheating power plant boiler as an example to illustrate the optimal way to realize the invention.

[0039] The feedwater pump system driven by a high-speed synchronous motor of the present invention includes a low-speed pre-pump (1), a low-speed pre-pump motor (2), an intermediate frequency variable frequency power supply (3), a high-speed synchronous motor (4), and a high-speed feedwater pump (5) ), the static excitation device (6); the intermediate frequency variable frequency power supply (3) is connected to the 3-phase 10kV, 50Hz factory busbar, and outputs 3-phase 1Hz to 100Hz AC with good waveform, and the output voltage increases with the increase of the output frequency. When the output frequency reaches 100Hz, the output voltage reaches 10kV; the high-speed synchronous motor (4) is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com