Manufacturing process for novel functional fabric

A production process and functional technology, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of not conforming to the trend of environmental protection, high cost, pollution, etc., to achieve good washability and adhesion, light weight, reduce environmental The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, this case is described in further detail.

[0020] This case involves the production process of a new type of functional fabric, which mainly includes the following steps:

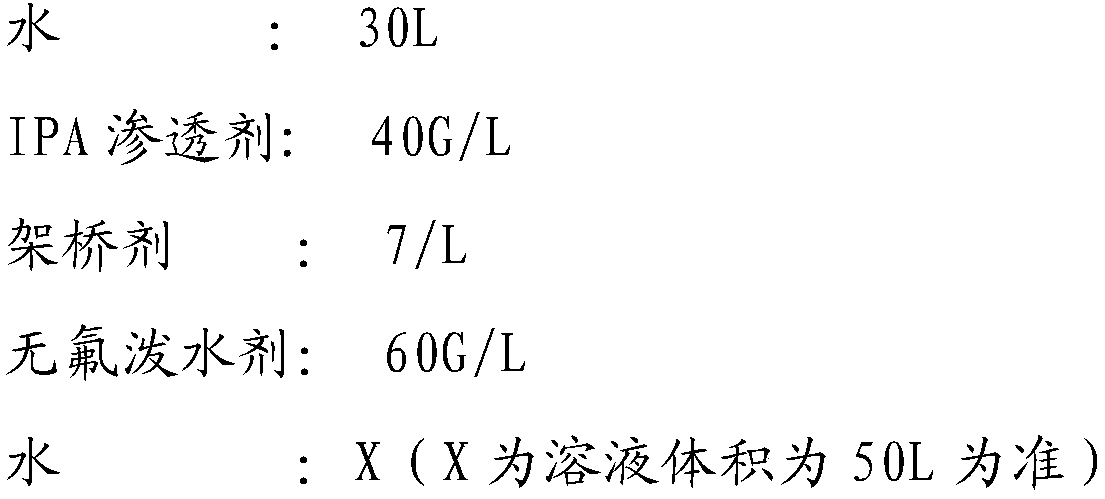

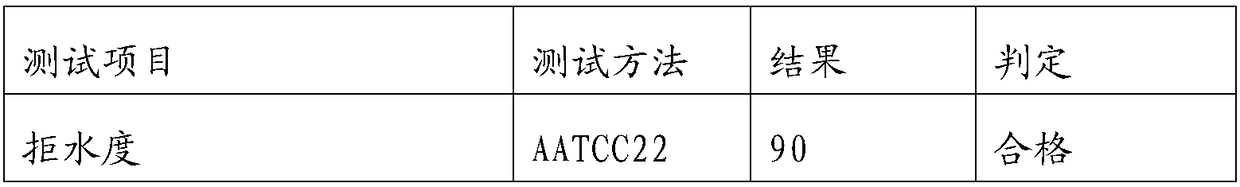

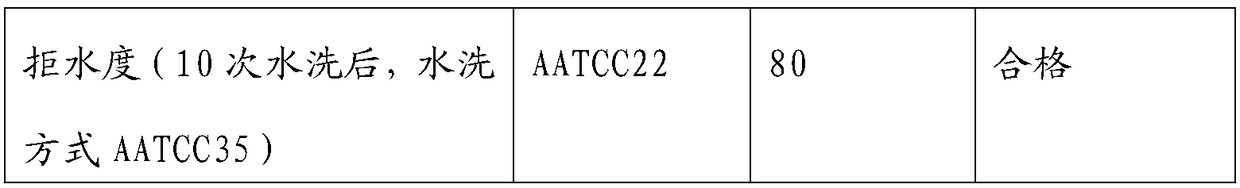

[0021] 1) Water-splashing treatment on dyed cloth;

[0022] 2) Calendering treatment before gluing;

[0023] 3) One-knife PU resin functional coating treatment: perform one-knife PU resin functional coating on the calendering surface, the functional coating is composed of the following components by mass: two-component polyurethane resin 60-70 parts, one-component type 25-30 parts of polyurethane resin, 5-10 parts of AC glue, 1-3 parts of silicon drying agent, 1-2 parts of bridging agent, solvent X; the amount of solvent X is added based on the viscosity of the rubber material 15000CPS.

[0024] Preferably, in the step 3), the dry glue coating amount of the one-knife PU resin functional coating is 13-15g. In addition, the knife type is 1.0R, the spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com