An immersion lithography machine immersion liquid flow field maintenance anti-collision system

A lithography machine and immersion technology, which is applied in the field of immersion lithography machine immersion liquid flow field maintenance anti-collision system, can solve the problems of negative exposure quality and impact, and achieve the effects of reducing impact, avoiding collision, and improving spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

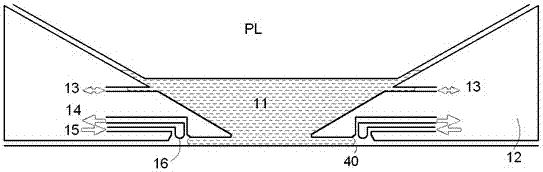

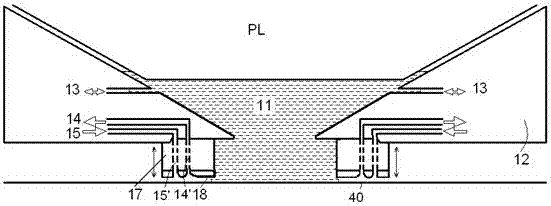

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] The purpose of the present invention is to provide an immersion liquid flow field maintenance system for an immersion photolithography machine. In the gap between the existing liquid supply system and the wafer stage, a buffer telescopic device is added, and the buffer telescopic device can freely Move in the direction of the optical axis or rotate about at least one axis perpendicular to the optical axis.

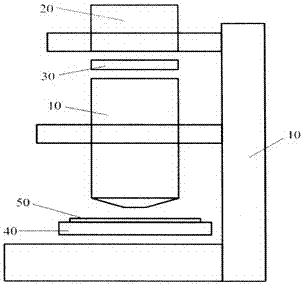

[0034] figure 1 It is a schematic structural diagram of an existing photolithography machine, which reveals a structure of an existing photolithography machine. In the lithography machine, the main frame supports an illumination system 20 , a projection objective lens 10 and a silicon wafer stage 40 on which a silicon wafer 50 coated with photosensitive photoresist is placed. The pattern of the integrated circuit on the reticle 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com