Label winding and sticking device

A labeling and labeling technology, applied in the direction of labels, etc., can solve the problems of difficult installation, disassembly, maintenance, high production process requirements, complex production and manufacturing, etc., to ensure relative position accuracy and consistency, high degree of automation, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

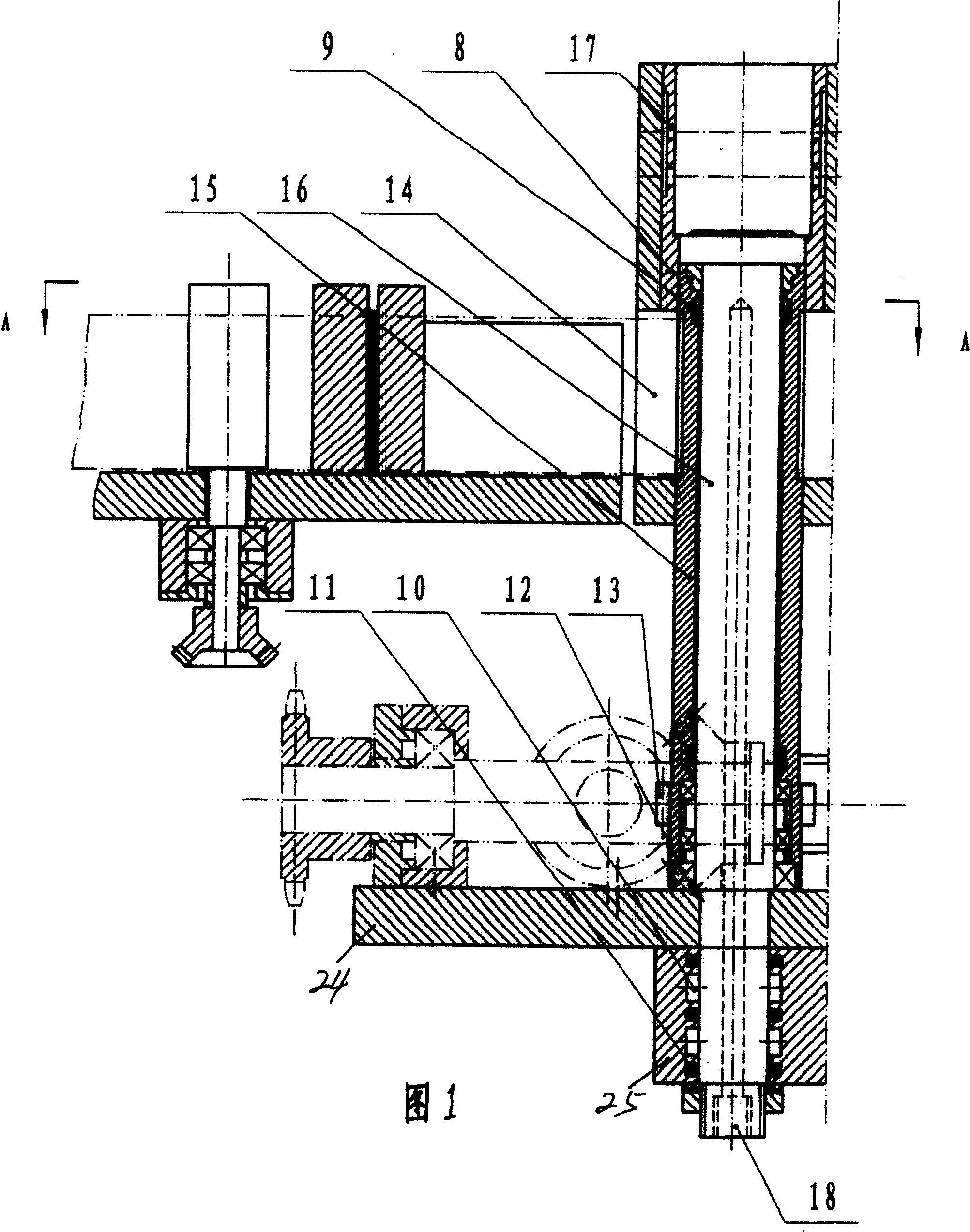

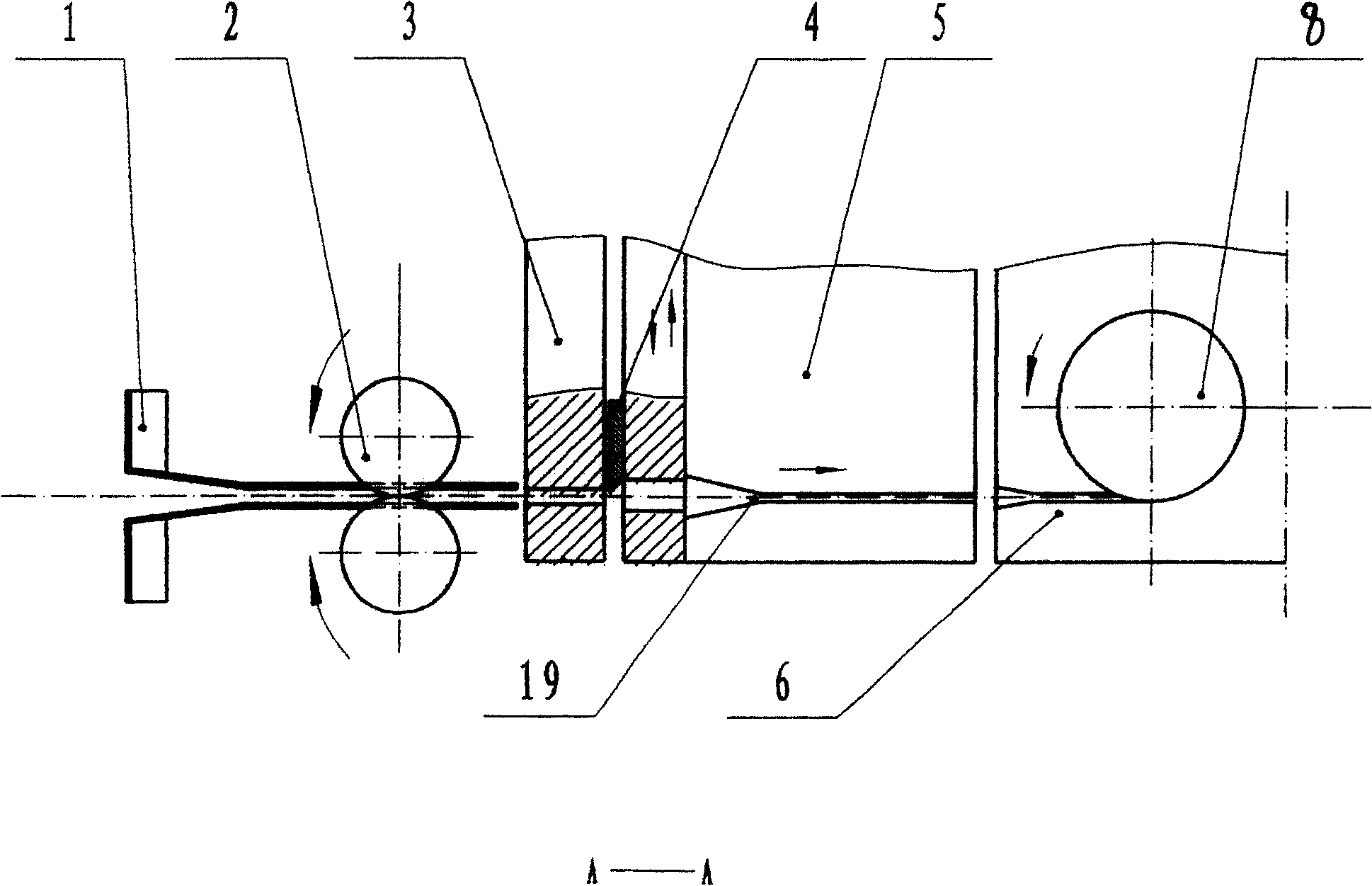

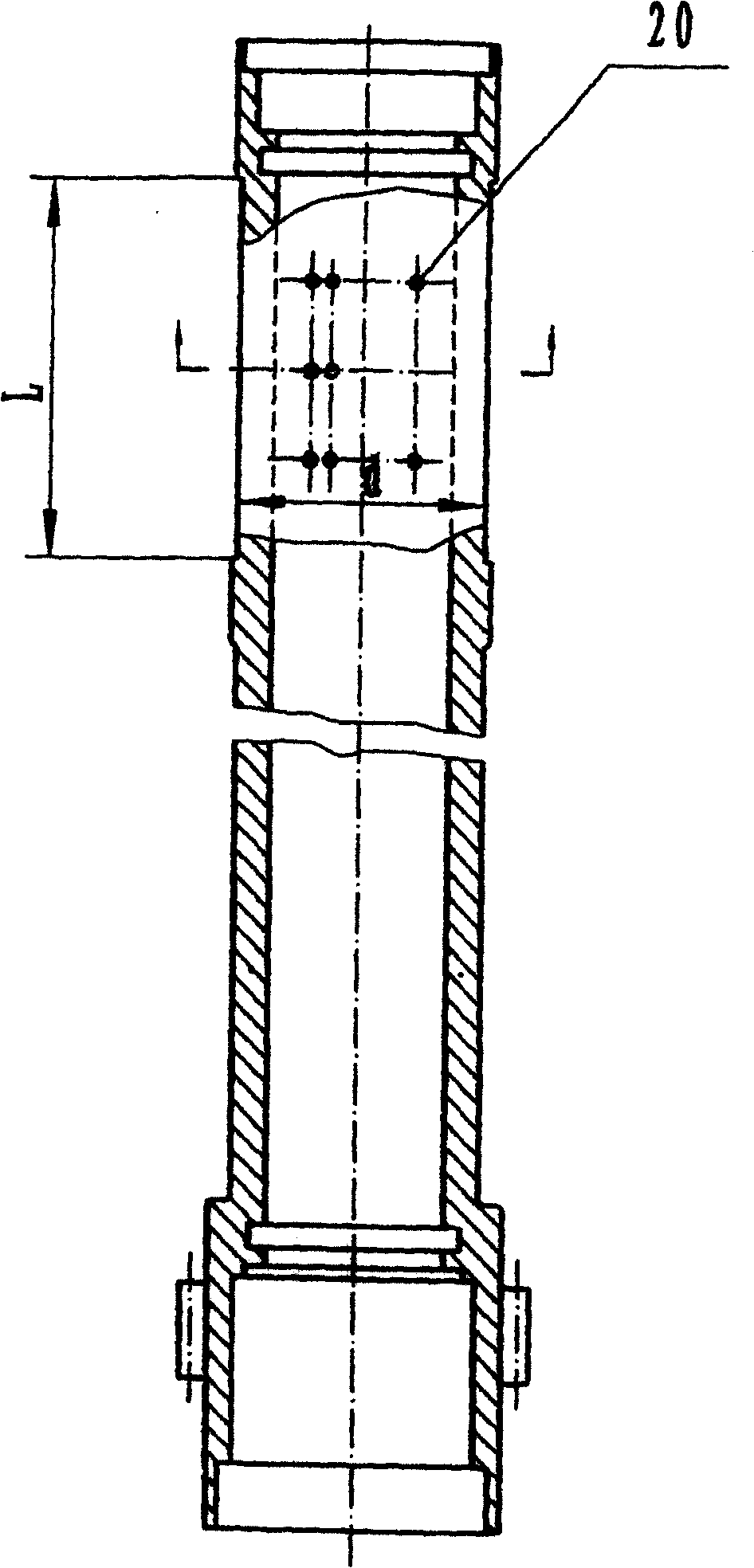

[0022] Embodiment 1: roll label labeling device, as shown in Figure 1, is provided with the suction label sleeve 15 with vacuum suction hole 20 in the label entry mold 14, is provided with the label suction mandrel 16 in the label suction sleeve 15, is positioned at The forming inner mold 8 above the standard entering mold 14 is sleeved on the outer periphery of the label suction sleeve 15, and the side wall of the forming inner mold 8 is provided with a vacuum suction hole 17. as shown in Figure 1 or image 3 Or as shown in Figure 5, the vacuum suction hole 20 on the side wall of the described label suction sleeve 15 communicates with the vacuum pipeline 21 in the described label suction mandrel 16, and the vacuum suction hole that is provided with on the molding inner mold 8 17 communicates with the vacuum pipeline provided on the side wall of the forming mold 6 . as shown in Figure 1 or figure 2 As shown, the standard entry die 14 is provided with a side gap entry channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com