Hybrid carbon nanotube reinforced wear-resistant anti-friction ceramic coating and preparation method thereof

A technology of ceramic coating and carbon nanotubes, which is applied in the field of cermet coatings, can solve the problem that there is no effective way to improve the strength of carbon nanotubes and coatings, and that carbon nanotubes can not fully utilize the crack resistance and wear resistance of carbon nanotubes to enhance coatings. Features, carbon nanotubes and low coating strength, etc., to achieve the effects of easy promotion and application, low curing temperature, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

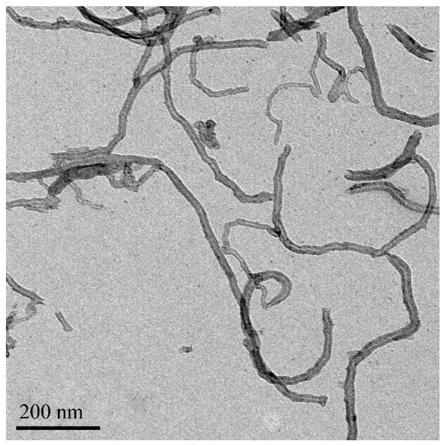

[0037] (1) Add 1 g of carbon nanotubes to 40 ml of mixed acid (HNO 3 :H 2 SO 4 =1:3) in the solution, react at 140° C. in an oil bath for 2 hours, and the obtained product is washed three times with absolute ethanol and deionized water, respectively, and centrifuged to dry to obtain acidified carbon nanotubes; acidified carbon nanotubes such as figure 1 shown.

[0038] (2) 1 g of zinc acetate and 5 ml of deionized water were added to 150 ml of diethylene glycol, and the reaction was carried out in an oil bath at 180° C. for 5 minutes to obtain a zinc oxide sol.

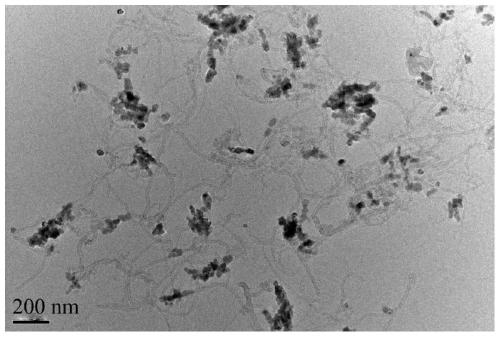

[0039] (3) 1 g of acidified carbon nanotubes were added to 150 g of zinc oxide sol, the oil bath temperature was 180° C., and the magnetic stirring was performed for 2 hours. Hybrid carbon nanotube composites. The resulting complex is figure 2 shown.

[0040] (4) Weigh an appropriate amount of ceramic aggregate, curing agent and adhesive. The content of the ceramic aggregate, curing agent and adhesive is: alum...

Embodiment 2

[0047] (1) Add 1 g of carbon nanotubes to 40 ml of mixed acid (HNO 3 :H 2 SO 4 =1:4) solution, react at 120° C. in an oil bath for 1.5 hours, and the obtained product is washed three times with absolute ethanol and deionized water, respectively, and centrifuged and dried to obtain acidified carbon nanotubes.

[0048] (2) 1 g of zinc acetate and 6 ml of deionized water were added to 160 ml of diethylene glycol, and the reaction was carried out in an oil bath at 200° C. for 3 minutes to obtain a zinc oxide sol.

[0049] (3) 1.5 g of acidified carbon nanotubes were added to 150 g of zinc oxide sol, the temperature of the oil bath was 200° C., and the magnetic stirring was performed for 1.5 hours. A hybrid carbon nanotube composite is obtained. .

[0050] (4) Weigh an appropriate amount of ceramic aggregate, curing agent and adhesive. The content of the ceramic aggregate, curing agent and adhesive is: alumina (35 microns) 55%; zirconia 2%; magnesium oxide 1%; zinc oxide 1%, a...

Embodiment 3

[0057] (1) Add 1 g of carbon nanotubes to 40 ml of mixed acid (HNO 3 :H 2 SO 4 =3:7) solution, react at 150° C. in an oil bath for 2.5 hours, and the obtained product is washed three times with absolute ethanol and deionized water, respectively, and centrifuged and dried to obtain acidified carbon nanotubes.

[0058] (2) 1 g of zinc acetate and 3 ml of deionized water were added to 140 ml of diethylene glycol, and the reaction was carried out in an oil bath at 160° C. for 6 minutes to obtain a zinc oxide sol.

[0059] (3) 0.2 g of acidified carbon nanotubes were added to 150 g of zinc oxide sol, the temperature of the oil bath was 160° C., and the magnetic stirring was performed for 2.5 hours. A hybrid carbon nanotube composite is obtained.

[0060] (4) Weigh an appropriate amount of ceramic aggregate, curing agent and adhesive. The content of the ceramic aggregate, curing agent and adhesive is: alumina (35 microns) 45%; zirconia 6%; magnesium oxide 4%; zinc oxide 4%, alum...

PUM

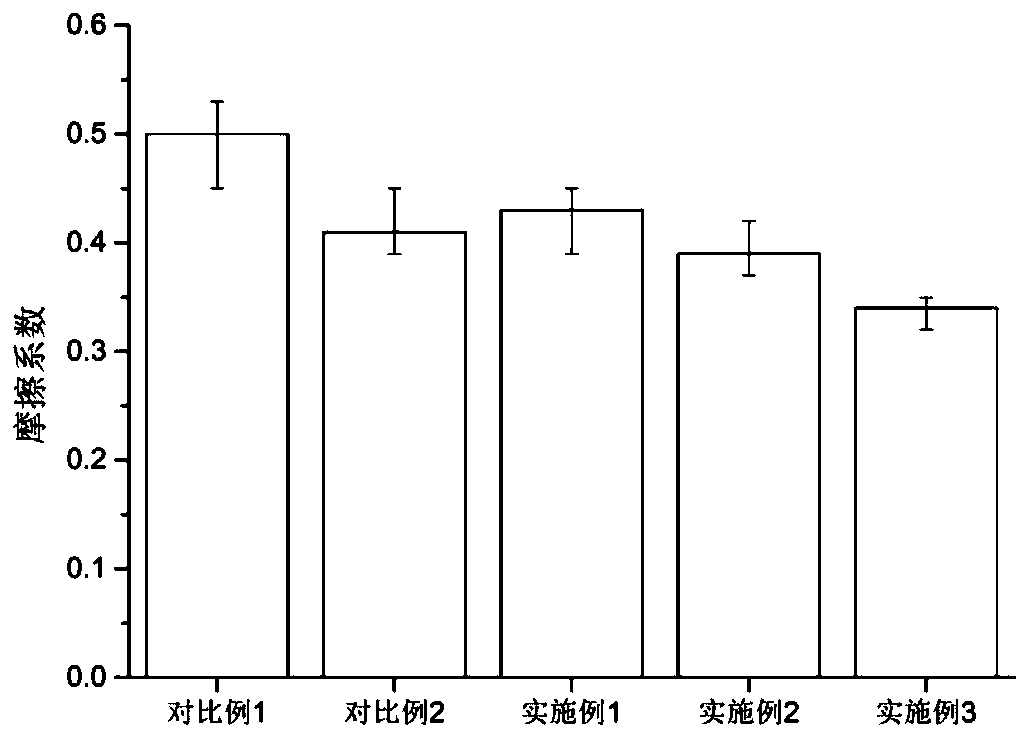

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com