Pure titanium or titanium alloy and surface hardening method thereof

A technology of titanium alloy and pure titanium, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of difficult control of hardened layer structure, rough surface hardened layer of pure titanium or titanium alloy, etc., and achieve improvement Hardening effect, good appearance, anti-oxidative discoloration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

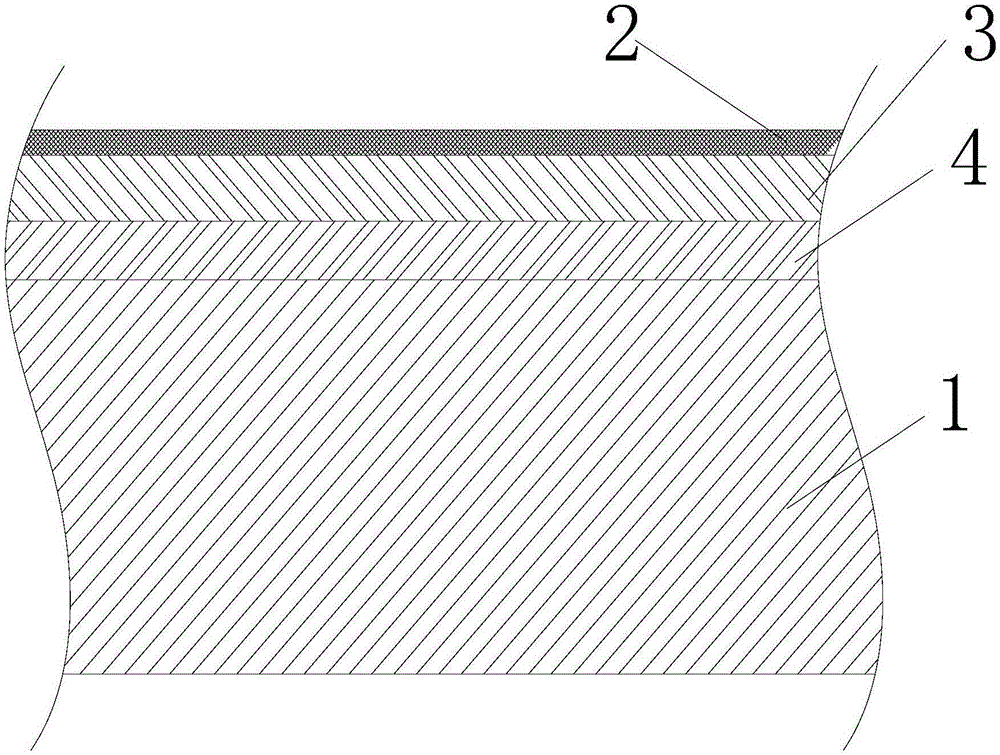

[0032] like figure 1 As shown, a kind of pure titanium or titanium alloy provided in this embodiment includes a substrate 1 made of pure titanium or titanium alloy, and is characterized in that: the surface of the gold substrate 1 is provided with three oxidation hardened layers, and the The three-layer oxidation hardening layer is respectively the surface transparent oxide layer 2, the outer diffusion layer 3 and the inner diffusion layer 4 from the outside to the inside.

[0033] The three-layer oxidation hardened layer on the surface of pure titanium or titanium alloy can well protect the base material 1 and make it have high hardness and high gloss.

[0034] Among the above-mentioned three layers of oxidation hardening layer, the thickness of the surface transparent oxide layer 2 is the thinnest, so that it will not cause discoloration due to light interference; the oxygen concentration in the outer diffusion layer 3 is the highest, and the thickness of the outer diffusion...

Embodiment 2

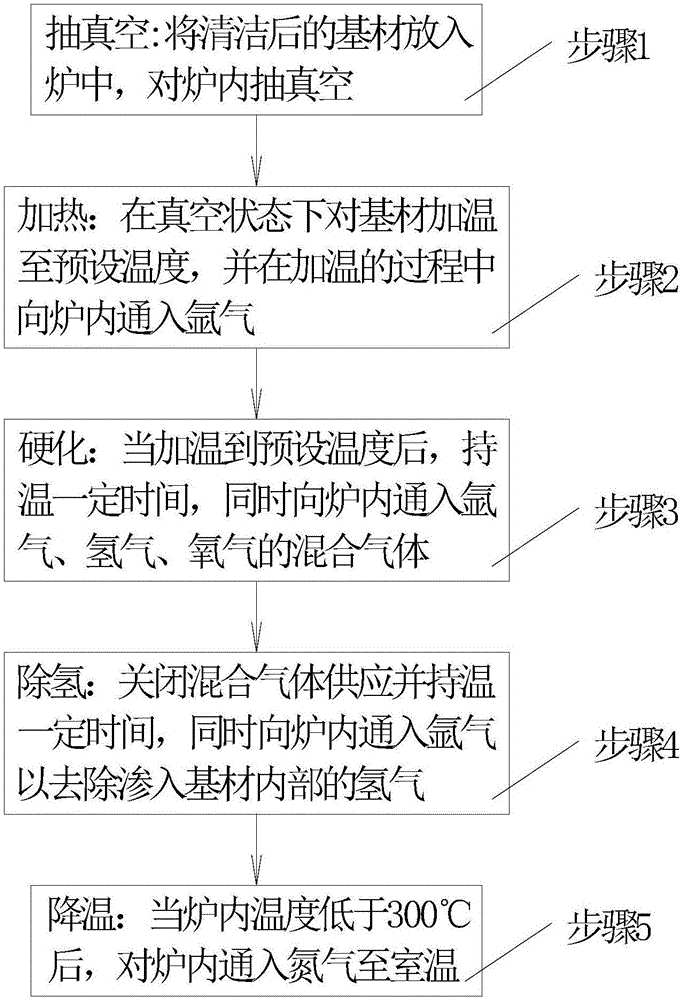

[0039] like image 3 As shown, a pure titanium or titanium alloy surface hardening method provided in this embodiment is characterized in that, comprising:

[0040] Step 1. Vacuuming: put the cleaned substrate into the furnace, and vacuum the furnace. The substrate is made of pure titanium or titanium alloy;

[0041] Step 2. Heating: heating the substrate to a preset temperature in a vacuum state, and feeding argon gas into the furnace during the heating process;

[0042] Step 3. Hardening: After heating to the preset temperature, hold the temperature for a certain period of time, and at the same time pass a mixed gas of argon, hydrogen, and oxygen into the furnace;

[0043]Step 4. Hydrogen removal: close the supply of the mixed gas and keep the temperature for a certain period of time, and at the same time pass argon gas into the furnace to remove the hydrogen gas infiltrated into the substrate;

[0044] Step 5, cooling down: when the temperature in the furnace is lower tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com