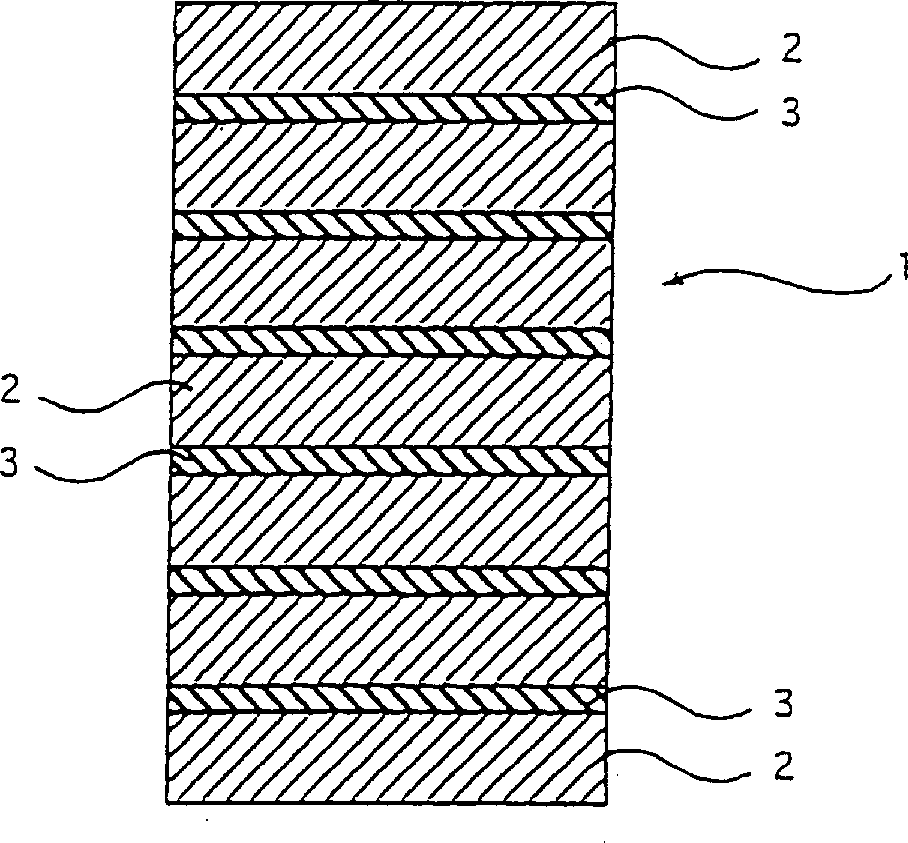

Rubber composition for seismic isolation laminates

A technology of rubber composition and laminate, applied in the direction of rubber layered products, shock absorbers, layered products, etc., can solve problems such as hardening and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

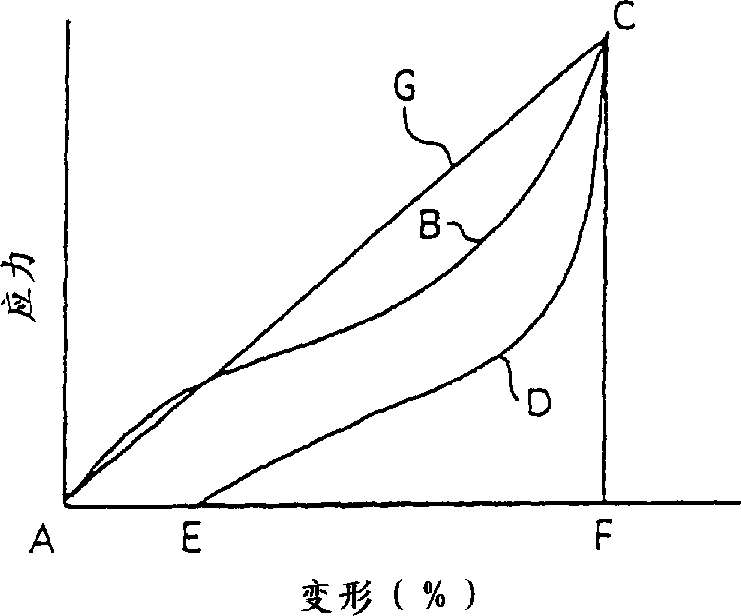

Method used

Image

Examples

example 1~7 and comparative example 1~10

[0047] Preparation of unvulcanized rubber composition: natural rubber and carbon black in various ratios shown in Tables 2 and 3; 5 parts by weight of aromatic oil per 100 parts by weight of rubber content; 40 parts by weight of resin; 5 parts by weight of zinc white; 1 part by weight of stearic acid; 1.5 parts by weight of sulfur; and 1.0 part by weight of CBS as a vulcanization aid were kneaded.

[0048] The rubber component and auxiliary agents other than vulcanization auxiliary agent (CBS) and sulfur were kneaded for 5 minutes in a Banbury internal mixer (model B, manufactured by Kobe Steel Works, 1.8 L). A vulcanization aid and sulfur were added to the mixture, and the mixture was kneaded in an 8-inch laboratory roll mill for 4 minutes to obtain the rubber composition.

[0049] The contents of the various components shown in Tables 2 and 3 are all in parts by weight. The properties of the carbon blacks used in the Examples and Comparative Examples are listed in Table 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com