Corrosion resistance aluminum alloy plate for aviation and preparation method of corrosion resistance aluminum alloy plate

An aluminum alloy sheet, corrosion resistance technology, applied in the field of aluminum alloy processing, can solve problems such as poor corrosion resistance, and achieve the effect of improving corrosion performance and toughness, excellent overall performance, high temperature resistance and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment also provides a method for preparing an aluminum alloy plate for aviation, the specific steps are as follows:

[0041] S1: design the composition of aluminum alloy, the mass percentage of the chemical composition of the aluminum alloy is:

[0042] 0.1% zirconium, 0.1% scandium, 4.0% zinc, 4.0% magnesium, 3.5% copper, 0.3% silver, 0.1% lithium, 1.2% manganese, 0.8% silicon, 0.25% titanium, 0.08% ruthenium, the balance is aluminum and not Impurities to avoid, impurity about 0.05%.

[0043] S2: preparing an aluminum alloy ingot, comprising the steps of:

[0044] S21: According to the composition of the aluminum alloy in step S1, carry out batching, melt under an argon atmosphere, and the melting temperature is 800 ° C. After the pure aluminum raw material is completely melted, add zirconium, copper, and silver in sequence, and stir for 5 minutes after the alloy components are completely melted. .

[0045] S22: Under an argon atmosphere, adjust the meltin...

Embodiment 2-5

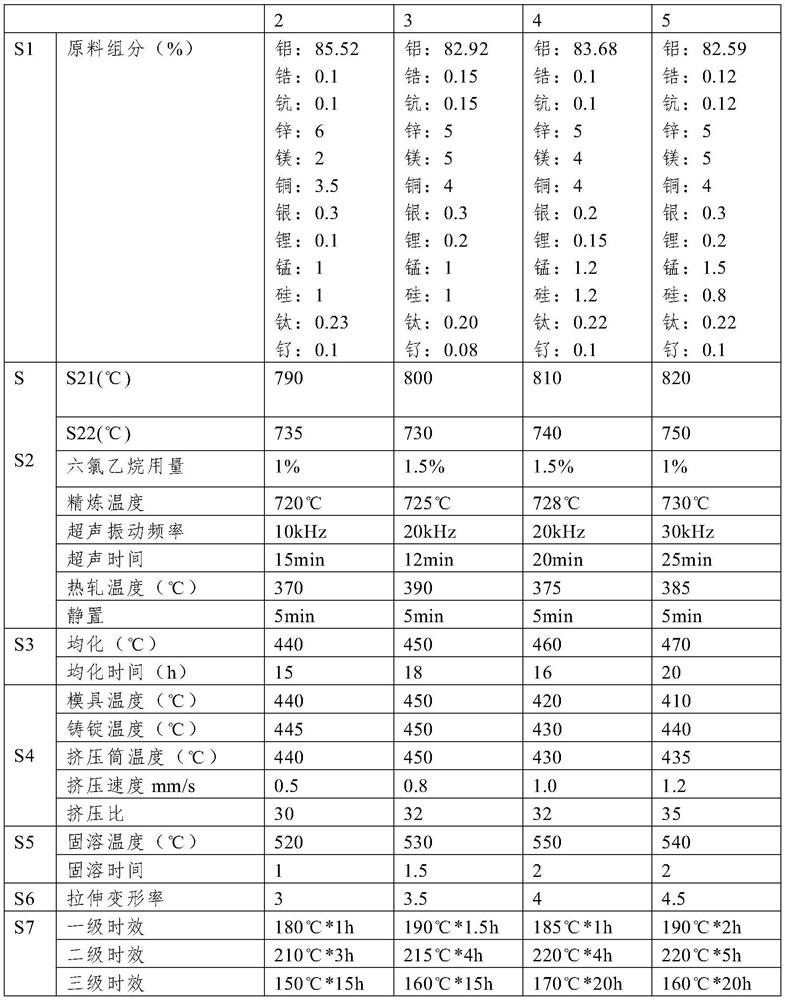

[0056] The process parameter conditions of the aluminum alloy plate preparation of embodiment 2-5 are shown in table 1:

[0057] The process parameter condition of aluminum alloy sheet material preparation in the embodiment 2-5 of table 1

[0058]

[0059] Example performance test

[0060] The properties of the aluminum alloy plates prepared in Examples 1-5 were tested, and the results are shown in Table 2.

[0061] The performance test result of the aluminum alloy sheet material that table 2 embodiment 1-5 makes

[0062] Example Vickers hardness (Hv) Yield strength MPa Tensile strength (MPa) Elongation (%) 1 190 562 656 12 2 178 536 610 10 3 185 560 624 10.5 4 184 555 638 11.6 5 175 520 605 9.4

[0063] It can be seen from Table 2 that the performance indicators of the aluminum alloy plates prepared in Examples 1-5 are: Vickers hardness 175-190Hv, yield strength 520-562MPa, tensile strength 605-656MPa, elongati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com