Method for molding aluminum and aluminum alloy powder

a technology of aluminum alloy and powder, which is applied in the direction of turbines, mechanical equipment, transportation and packaging, etc., can solve the problems of inconvenient powder injection molding method, difficult inability to manufacture high-density sintered bodies, etc., to achieve good corrosion and weathering resistance, low density, and high thermal conductivity and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

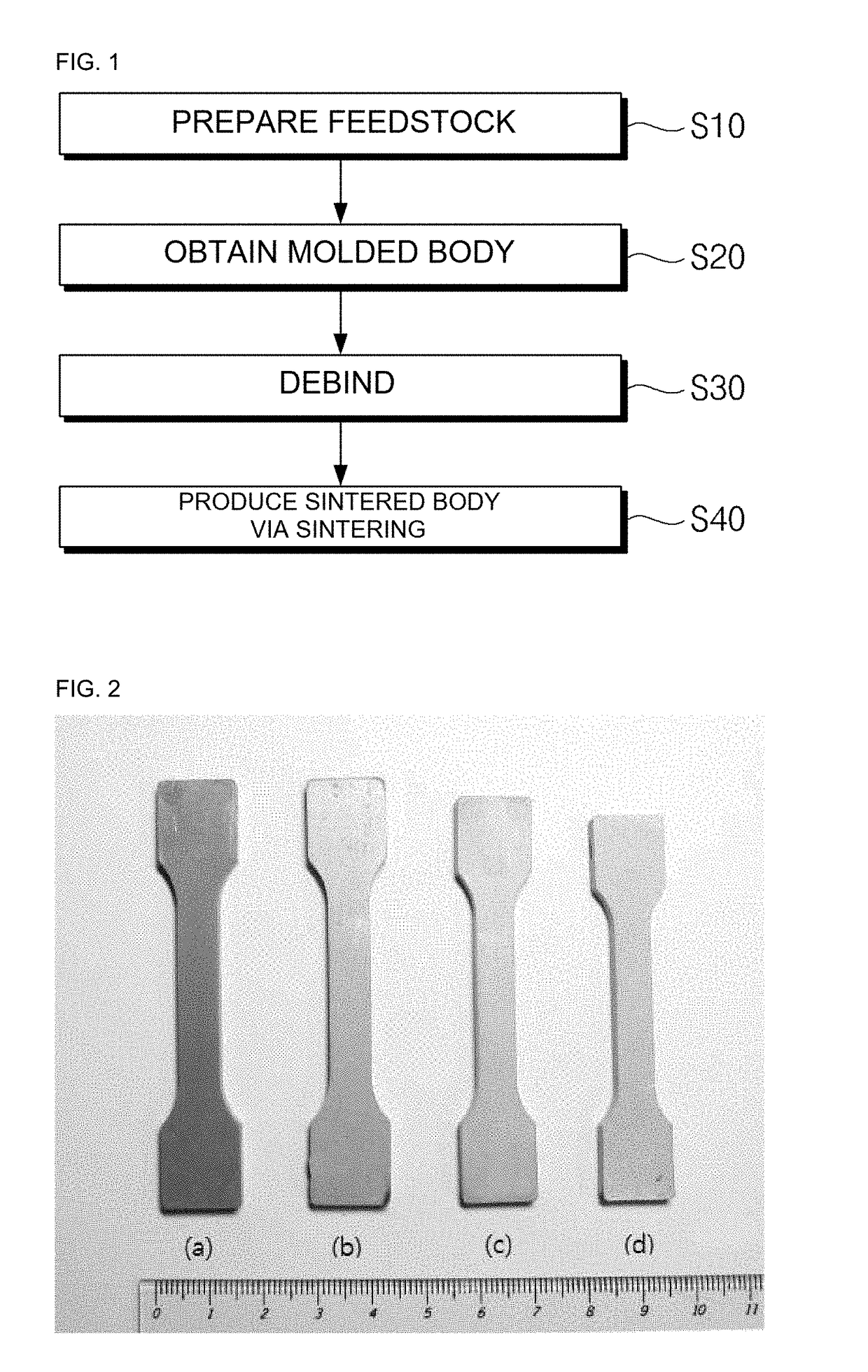

[0088]A 300 g of feedstock having a solids loading of 62% was prepared by kneading aluminum powder having purity of 99.5% and an average particle size of about 6 μm (MEP 105, Ecka Granules, Germany) and an organic binder containing 70 wt % of paraffin wax, 16 wt % microcrystalline wax, 6 wt % maleic anhydride grafted polyethylene (DP-730, Hyundai EP, Korea) as a polyethylene copolymer having a carbonyl group, and 8 wt % polyethylene wax in a pressurized kneader at 140° C. for 2 hours. The resulting feedstock was crushed into about 6 mm sized granules, charged into an injection molding machine having clamping force of 80 tons, and injection-molded to produce an injection molded body of a tensile test specimen of ASTM subsize standard (ASTM E8).

[0089]The injection molded body was cut and inspected visually to examine presence of an internal defect and also through an X-ray non-destructive test, and it was confirmed that the injection molded body was defect-free.

[0090]After placing the...

example 2

[0093]About 50 g of feedstock having a solids loading of 65% was prepared at 135° C. for 2 hours by kneading, in a twin-cam mixer (Rheocord 90, Haake, Germany), gas-atomized 99.8% purity aluminum powder (Aluminum powder company, U.K.) having an average particle size of about 6 pm and an organic binder containing 60 wt % paraffin wax, 26 wt % microcrystalline wax, 8 wt % maleic anhydride grafted polyethylene (DP-730, Hyundai EP, Korea) as the polyolefin copolymer having a carbonyl group, and 6 wt % polyethylene wax.

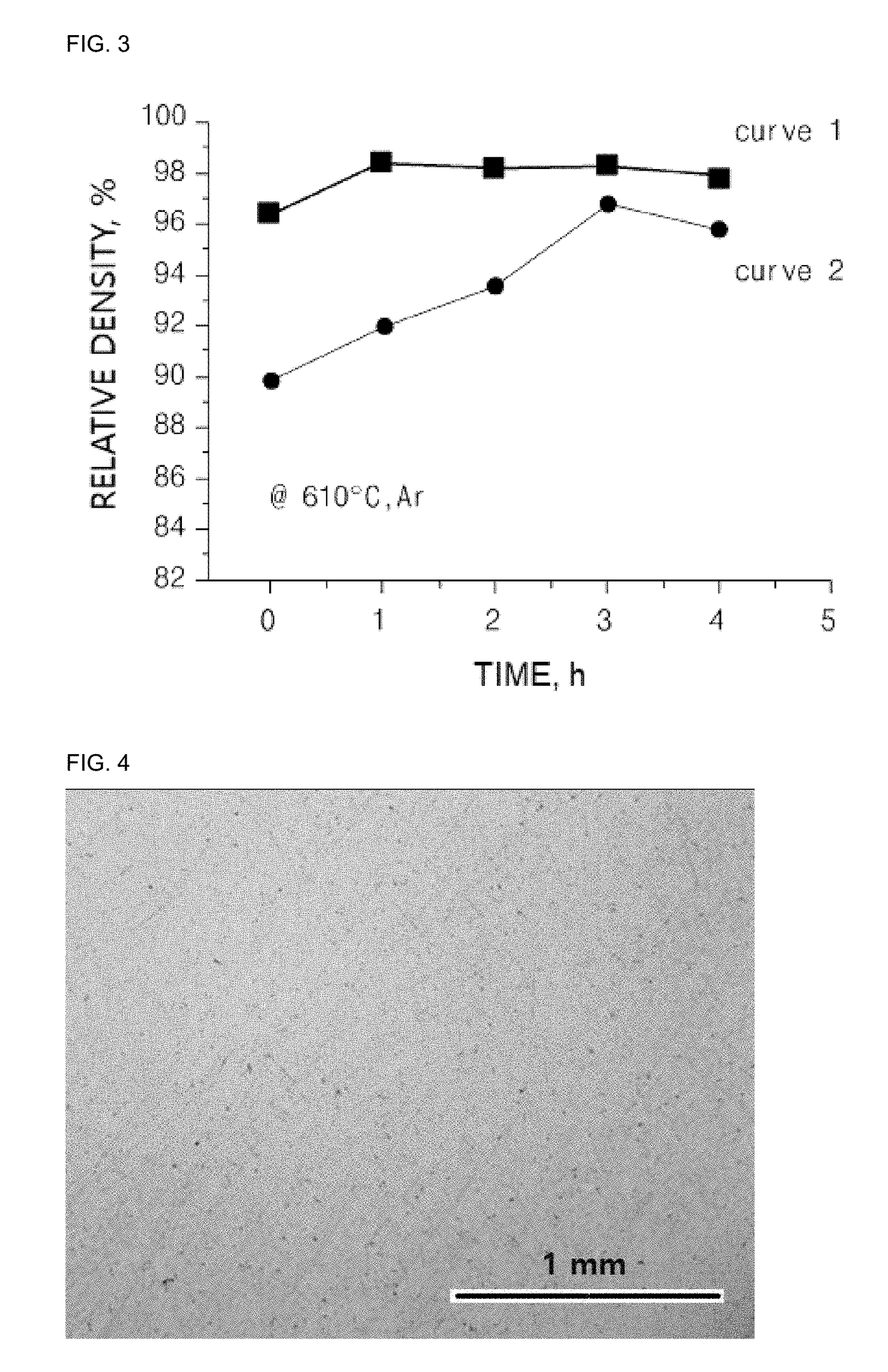

[0094]The feedstock was crushed into about 3 mm granules by using a steel mortar and pestle, charged into a steel mold preheated to 120° C., and then compression-molded under pressure of 20 MPa to manufacture an molded body of a small and non-standard tensile test specimen having a total length of 50 mm, a length of a parallel section of 20 mm, a width of a grip section of 16 mm, and a width of the parallel section of 5 mm.

[0095]After placing the molded body of the tensile...

example 3

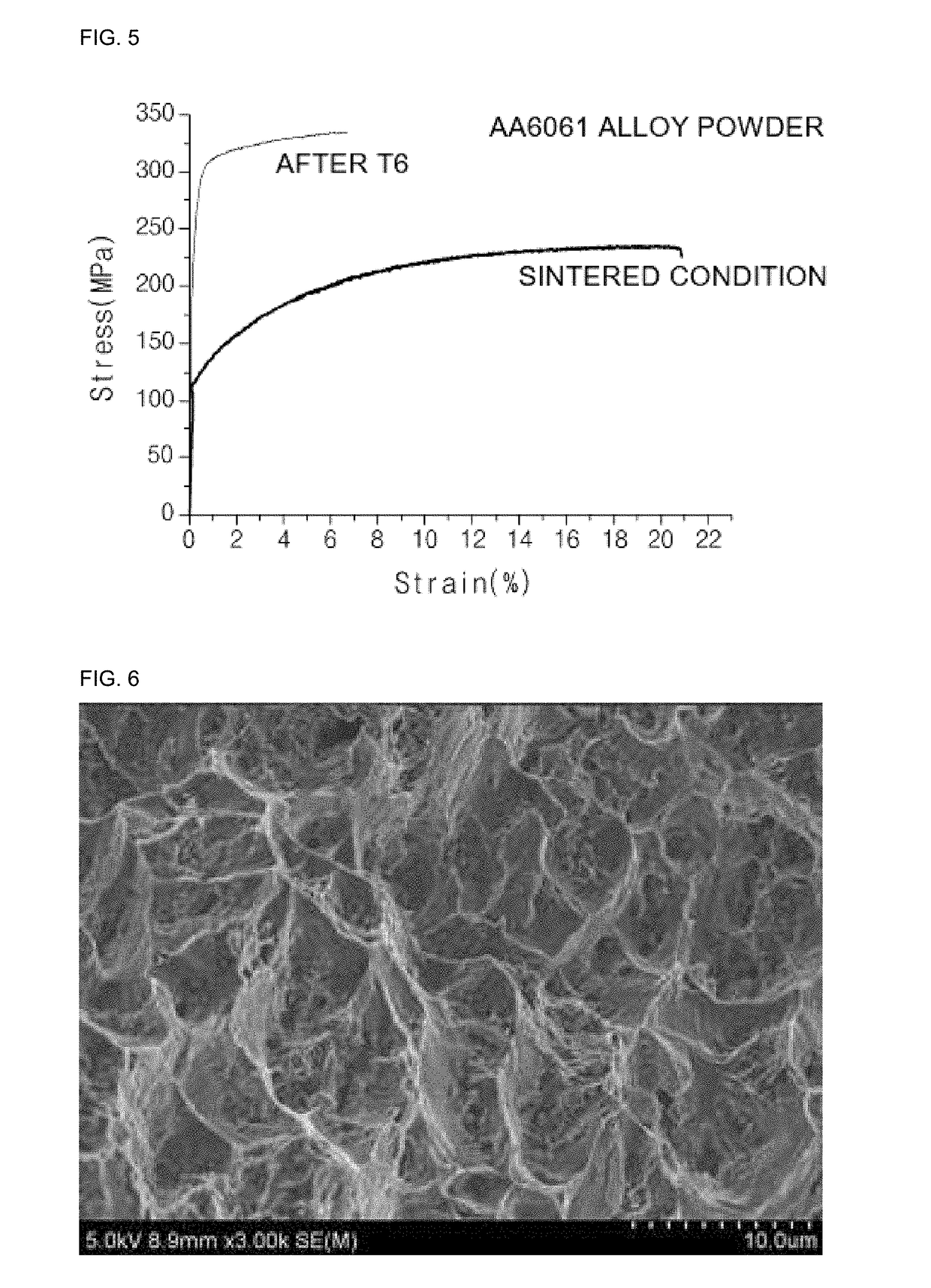

[0096]A 500 g of feedstock having a solids loading of 67% was prepared by kneading gas-atomized AA6061 aluminum alloy powder (Al-0.91 wt % Mg-0.70 wt % Si-0.26 wt % Cu, Aluminum powder company, U.K.) having an average particle size of about 6 μm with an organic binder containing 58 wt % paraffin wax, 26 wt % microcrystalline wax, 10 wt % maleic anhydride grafted polyethylene (DP 730, Hyundai EP, Korea) as a polyolefin copolymer containing a carbonyl group, and 6 wt % polyethylene wax, in a double-blade planetary mixer at 140° C. for 2 hours. The resulting feedstock was crushed into granules, charged into a hopper of an injection molding machine, and injection-molded to form a defect-free injection molded body of a tensile test specimen without any internal defect. In addition, another specimen having a disc shape with a diameter of 20 mm and a height of 4 mm was prepared via warm compression molding using a steel mold preheated to 118° C.

[0097]The tensile test specimen was placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com