Device for manufacturing hollow filter stick

A production device and hollow technology, applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problems of high price, limited filtering effect of harmful components, complex structure, etc., to increase the steam hardening device, shorten the curing time, and promote hardening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

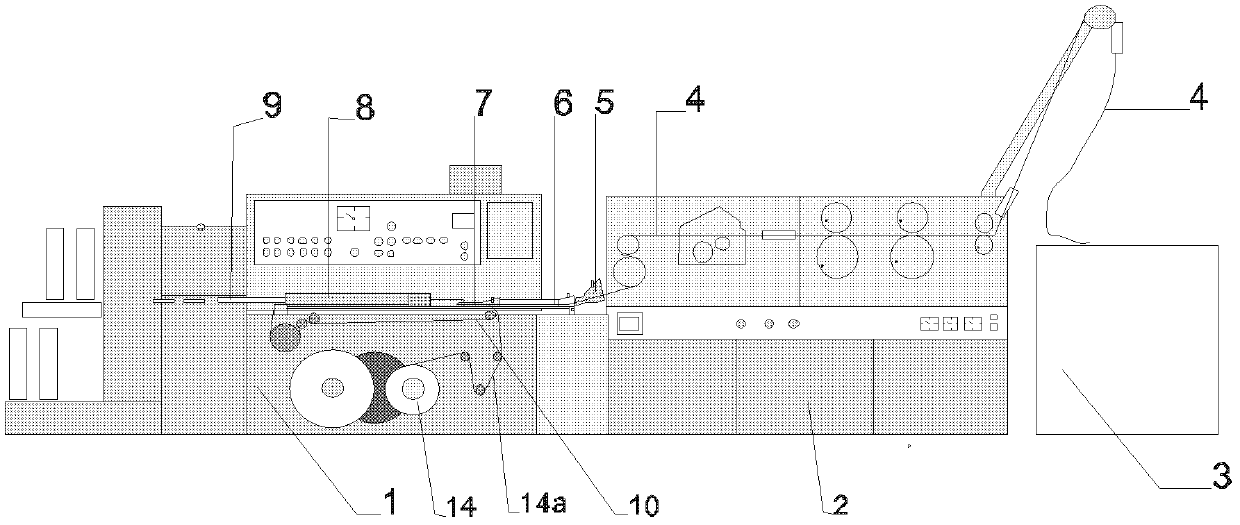

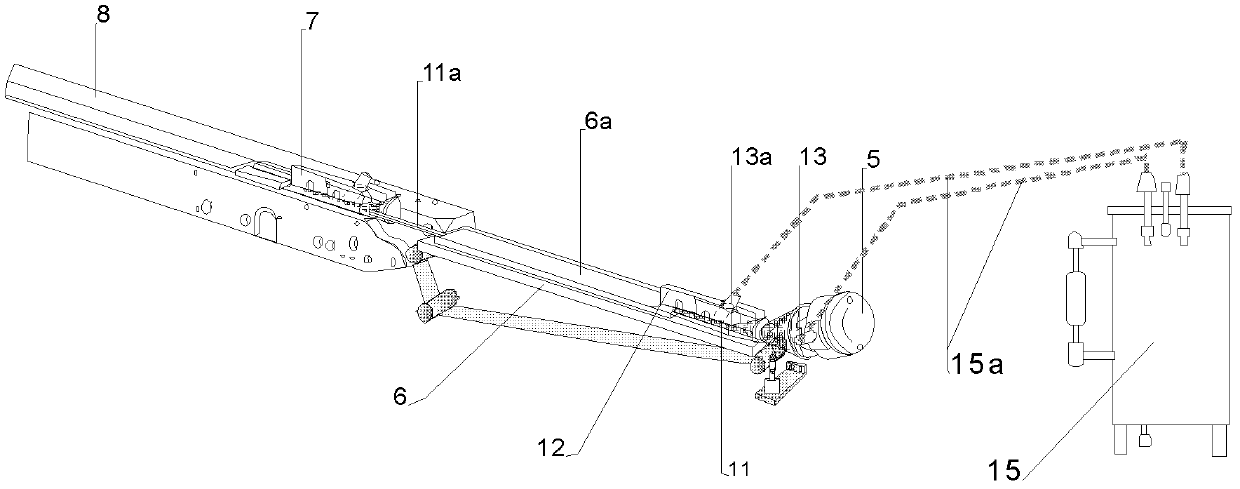

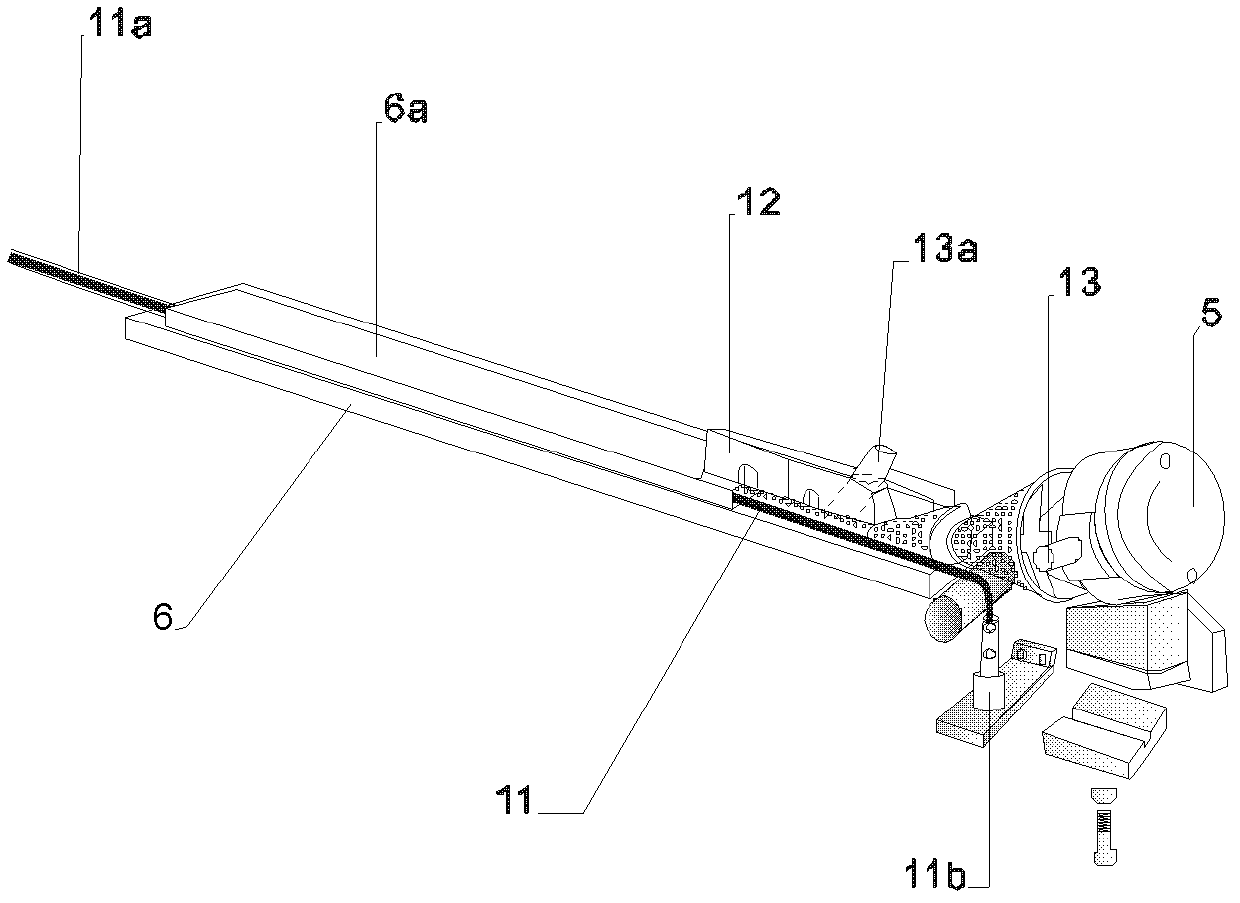

[0018] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] A production device for hollow special-shaped filter rods, including a forming machine 1 and an opening machine 2, a certain distance is spaced between the forming machine 1 and the opening machine 2, and a steam hardening device 6 is installed in this distance, the described The steam hardening device 6 includes a group of high-pressure air nozzles 5, forming tongues 12, a tape cloth mechanism 10 for clamping the tow tape to move forward, a bong channel 6a, and a steam generator 15; the tape cloth mechanism 10 and the host drive device connected, and the high-pressure air nozzle 5 is connected with the opener 2 for receiving the ribbon 4 conveyed by the opener 2, the output end of the high-pressure air nozzle 5 communicates with the forming tongue 12, and sends the tow belt 4 into the forming tongue 12 Among them, the front end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com